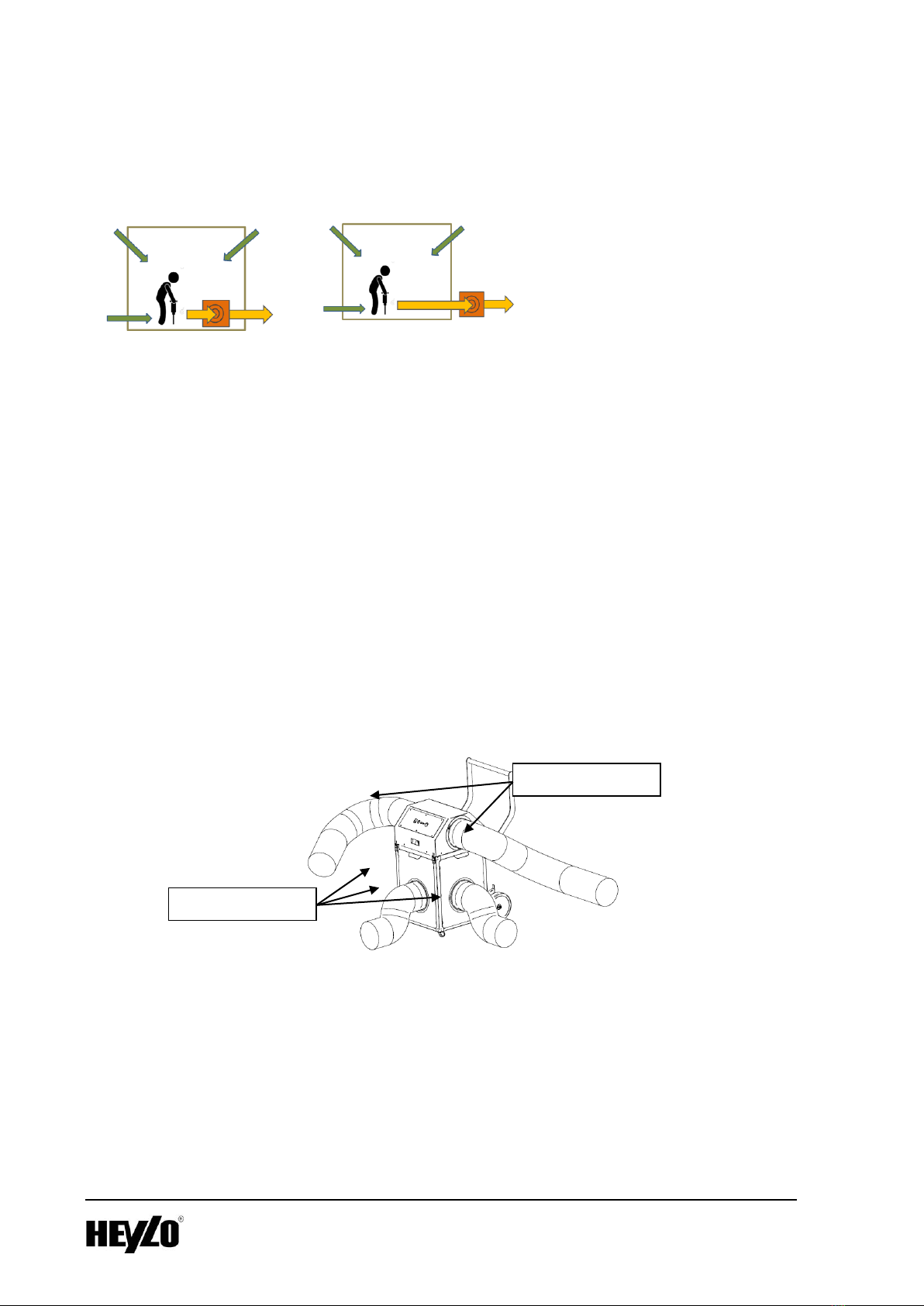

Ensure move of the suction hoses in the work area as close to time as possible. Hoses should be laid

without kinks, if possible, and in a straight line to the air filter. If and when necessary, auxiliary

constructions have to be set up for overcoming differences in height, for example (by chamfering of

supporting wood nailers, for example). In the area of the suction hoses, the constriction of the cross-

section by kinks increases the suction air flow. In the exhaust air hose, the exhaust air flow counter the

cross-sectional constriction by kinks.

The suction hose has to be arranged in such a way that contaminated air is removed from the

breathing area of the employees, and fresh air and/or purified air is supplied to the employees.

The purified exhaust air of the air filter has to be passed to well ventilated areas and/or to the outside.

A return of purified air into the working area is permitted only, if sufficient base ventilations with fresh

air is ensured at the same time. A second air filter may be set up for air ventilation, if and when

necessary. Please observe the national health and safety regulations.

Required air exchange: The required air exchange depends on the type and volume of air pollutants.

Correspondingly, air exchange rates of between triple and 20-fold of the room volume may be

required.

The professional associations recommend a 15-fold air exchange. The occupational exposure limit

value is 1,25 mg/cum in case of A dusts and 10 mg/cum for E dusts (TRGS 900).

Example: A 15-fold air exchange is required for a room volume of 100 cum.

The required air volume is 15 x 100 cum, thus at least 1,500 cum/h. When the filter

display has been activated, HEYLO PF 3500 continues to have an output of approx.

1,700 cum/h.

A sufficient air exchange is thus ensured.

The precise requirements are listed in the installation guidelines mentioned in chapter (8).

(7) Filter / change of filter

Filter system: The air filter PF 3500 uses a two-stage filter system which uses the latest HEPA filter

technique. The first filter stage consists of three pre-filters and the main filter stage of one robust

HEYLO drum filter in various filter classes.

Change of filter: Independent of the change of filter indicator, both filters have to be replaced after

every use involving contaminants. If the composition of the particles drawn in is not known, the filter

should be replaced completely after use on the respective building site. Both filters have to be

replaced so that the soiling (contamination) is not passed into clean areas.

Service life of filter: The service life of the filter depends on the quantity of dust drawn in. Very fine

dust may drastically reduce the service life. Saturated pre-filters have to be replaced; saturated main

filters can be cleaned up to a maximum of five times.

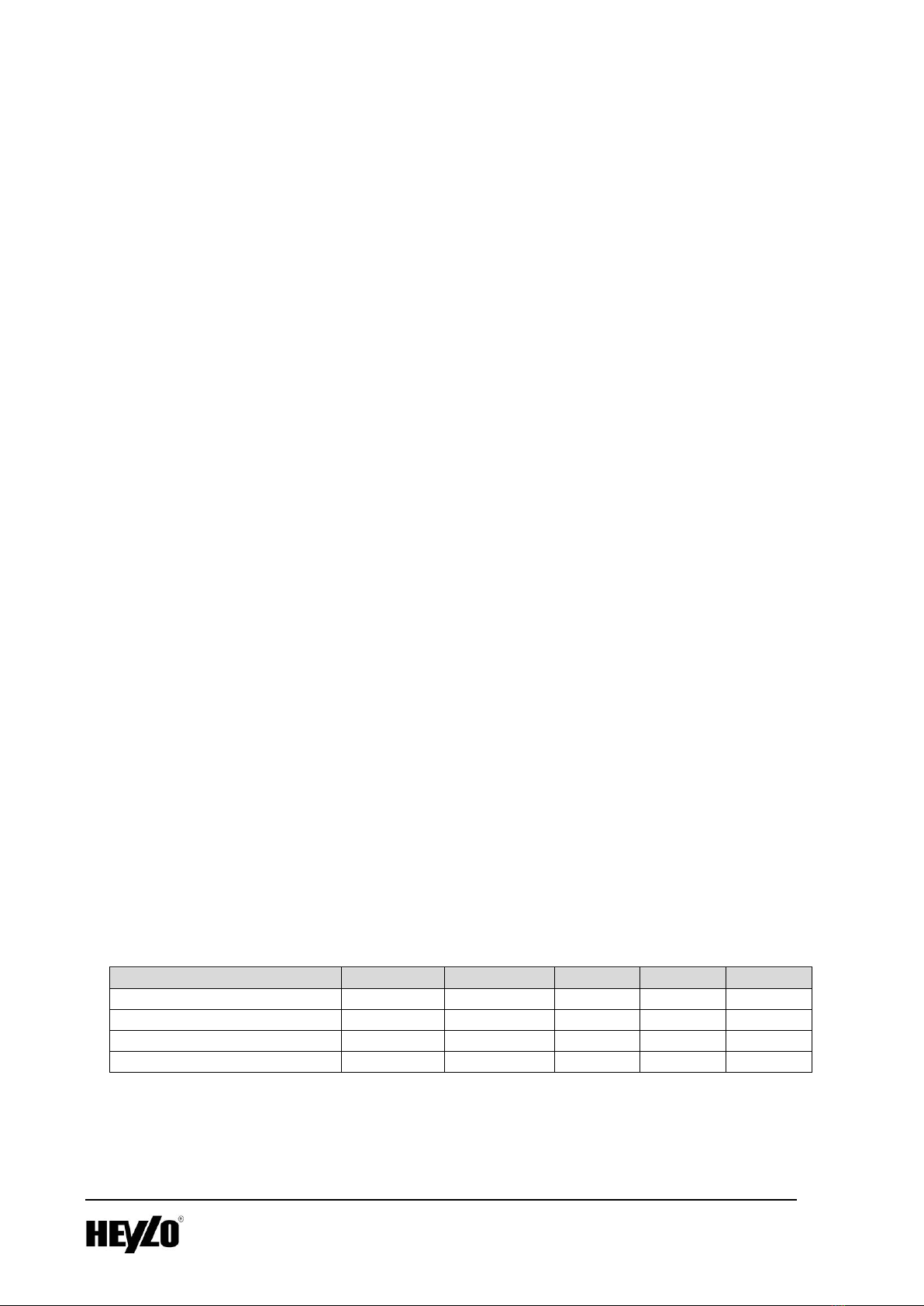

The calculated service life of the G4 filter and dust class H (HEPA H14) is rendered in the following

table: