Aquion OptiPure BWS175 User manual

BWS175

Simple Install

Guide

970-09729 Rev. A - 03/19

©2019 Aquion, Inc. All Rights Reserved

Access manuals, spec sheets and additional educational

materials for foodservice water treatment at our website.

www.optipurewater.com

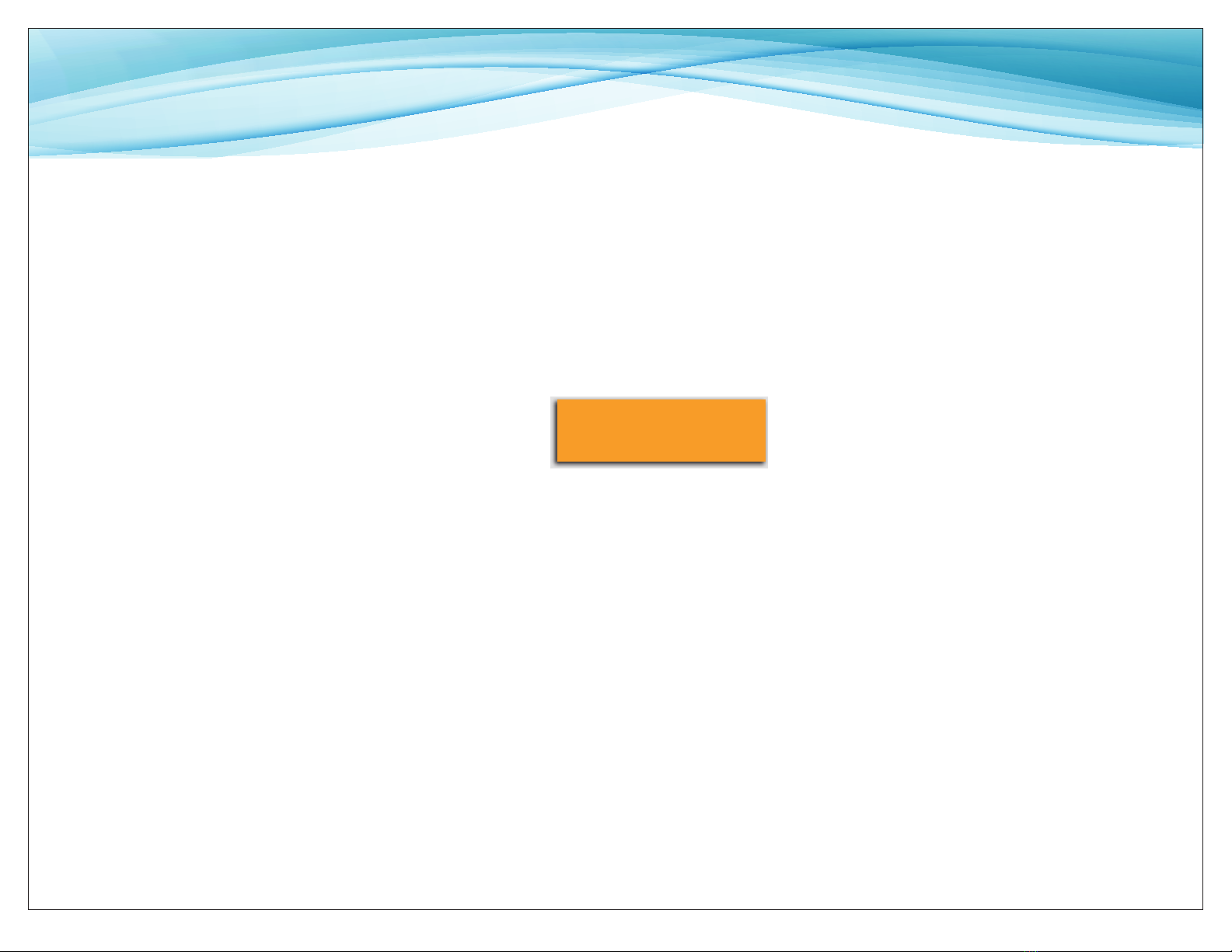

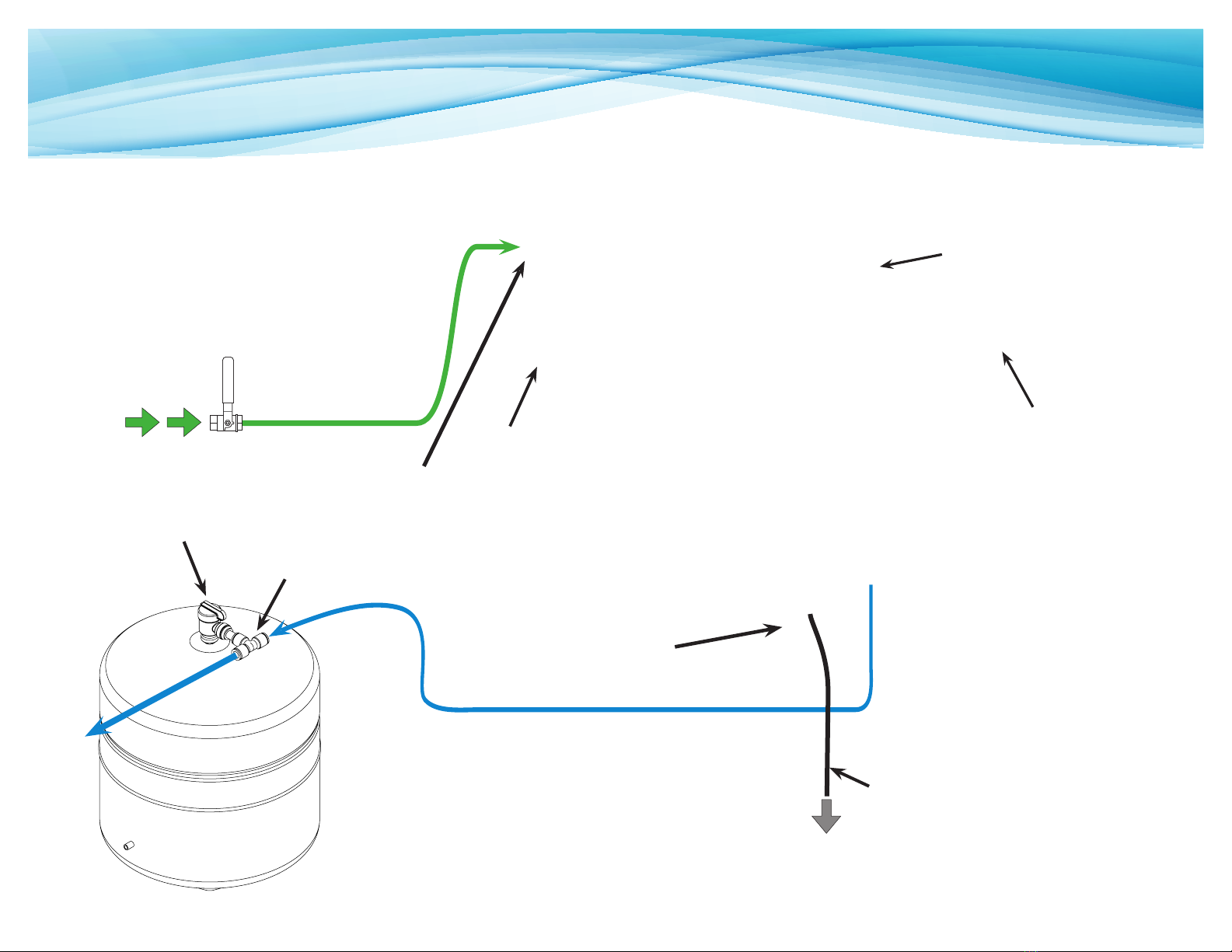

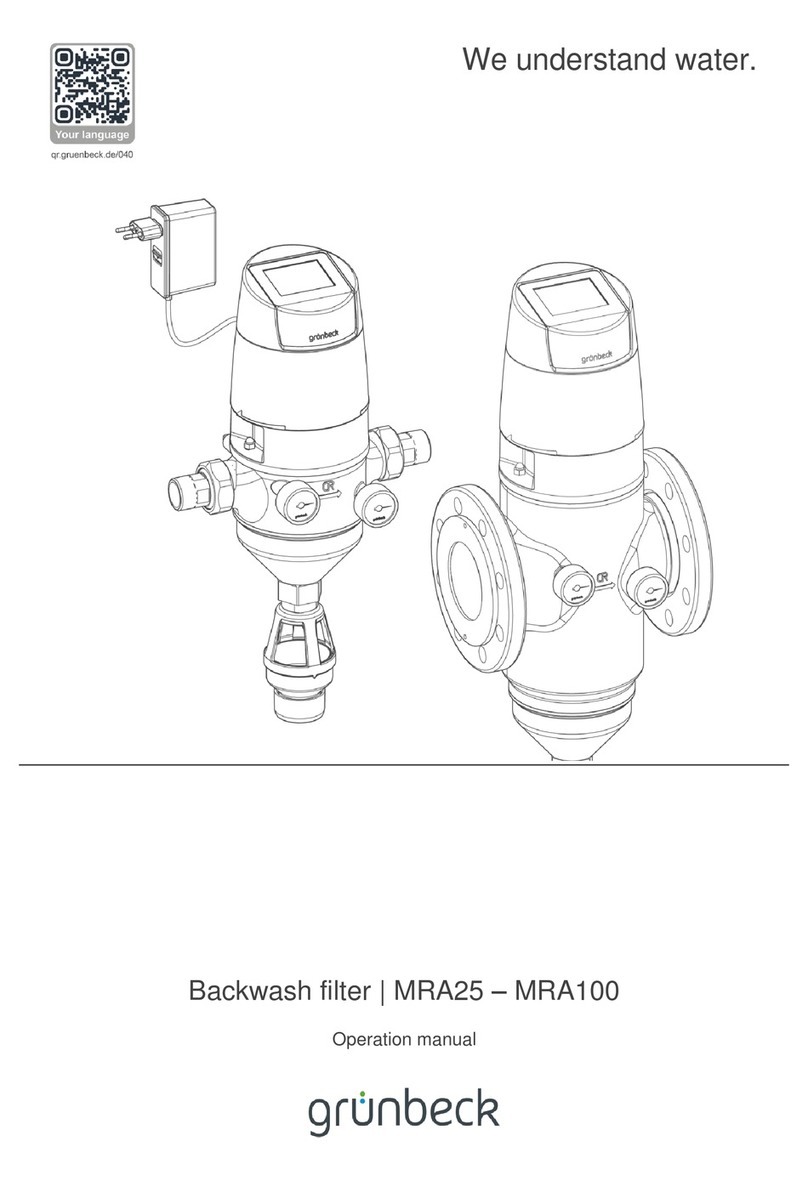

BWS175 Simple Install Guide 2

2.5 gals. Storage Tank Shown

Completed BWS175

Installation

Service Contact

For local maintenance and service information, please

contact your nearest Authorized Service Representative.

Service inquiries may be directed to technical support at:

OptiPure

101 South Gary Avenue, Suite A

Roselle, IL 60172 USA

Phone #: 972.881.9797

Environmental Conditions

1. Altitude up to 6562 ft (2000 m).

2. Ambient Temperature of 40˚ - 105˚F (5˚ - 40˚C).

3. Maximum Relative Humidity 80% at 88˚F (31˚C).

4. Installation Category II.

5. Pollution Degree II.

6. Indoor use only, protect from elements.

Safety Instructions

1. Please read and follow these instructions when

connecting and using the system.

2. Securely bolt processor to wall before operating.

3. Avoid cross-connections and install on cold water supply

only.

4. Use approved air gaps when connecting to drain lines.

5. Do not exceed system pressure rating and use water

hammer arrestors when water hammer is evident.

6. Turn off feedwater supply before filter or membrane

cartridge replacement.

General Information

The BWS175 is certified to operate under the following

conditions:

BWS175 Simple Install Guide 3

vInstallation Requirements

Operating a system on water supplies outside

of the parameters listed below may lead to

premature membrane failure. This product is

for commercial use only and must be installed

and maintained in accordance with

manufacturer’s guidelines and local regulatory

plumbing codes.

Operating Parameters

Typical Membrane TDS Rejection: 97+% Feed

Temperature: 40˚ - 100˚F (4˚ - 38˚C) Feed

Pressure: 50 - 80 psi (3.4 - 5.5 bar) at 1 gpm

Production (at 77˚F, 60 psi to atmosphere):

175 gpd (7.3 gph)

Recovery: Up to 33%

IMPORTANT NOTE: The production rate is

strictly dependent on feedwater temperature

and pressure.

For example: Operating pressure of 30

psi will reduce production by 50%, or

48˚F feedwater will reduce production by 50%.

Location

The system should be installed indoors, within

25 feet of the equipment water is being

supplied to, and protected from the elements.

Do not let the processor or storage tank freeze

or be exposed to rain or direct sunlight.

Feed Water Connection

An adequate flow and pressure of water to the

unit is essential for successful operation.

Drain

A drain should be located within 10 feet of

the system. Drain must allow a minimum ow

of 2 gals./min. Compliance with most local

plumbing codes requires installation of an

approved air gap in the drain line. The drain

connection should be accessible for system

set-up and service.

Feedwater Chemistry

Feed TDS: Up to 1200 ppm

Feed pH: 6 - 10

Hardness: 12 grains or less

Free Chlorine: <2 mg/L

Iron (Fe): 0.1 mg/L maximum

Turbidity: <0.05 NTU

Manganese: 0.05 mg/L maximum

Hydrogen Sulde: 0.0 mg/L

Note: The presence of silica or occulants

such as alum or cationic polymers in the

feedwater may cause membrane fouling and

may require special pretreatment. Please note

that membrane failure due to fouling is not

covered by the warranty.

Storage Tank

The tank must be located within 10 feet of

the water processor. The oor beneath the

storage tank should be smooth, clean and

free of sharp objects that could puncture the

bottom of the tank.

Optimized Water Lines to Equipment

Tubing, piping and associated ttings used to

connect optimized water to equipment should be

food grade material with a minimum pressure rating

of 75 PSI. Non-metal, plastic pipe or reinforced hose

or tubing are recommended. For distribution runs

longer then 15 feet use larger inside diameter tubing

or hose to minimize pressure drop.

BWS175 Simple Install Guide 4

vBWS175 Installation Diagram

Plumbing should be performed in

accordance with local codes.

Feed Water Line -

Green 3/8” - from Feed Water

Valve to Feed Water Inlet

Feed

Water Bypass Valve

Drain Line -

Black 1/4” - from

Permeate Pump to Drain

Reject Water

(To Drain)

User-Supplied

Feed Water

Valve

AMS-Q15 Membrane

Cartridge

To Tank Connection

When installing, locate the storage

tank as near the equipment as

possible to maximize water pressure

and ow. Cut tubing to an efficient

length using a proper tube cutter for

a clean, square cut. When routing

and securing tubing avoid loops or

kinks.

Membrane Reject

Connection

Optimized Water Line to Tank

- Blue 3/8” - from Processor “To

Tank” Connection to Tank Inlet

Storage

Tank Inlet (On Valve)

Optimized Water Storage Tank

- 2.5 gals. Bladder Tank Shown

Storage Tank

Valve

(Normally Open)

CTO-Q10 Pre-Filter

Cartridge

Feed Water Inlet

Water Processor

Optimized Water to

Equipment - Blue 3/8" -

from Tank to Equipment

IMPORTANT - PROTECT PROCESSOR AND TANK

FROM THE ELEMENTS. DO NOT INSTALL IN DIRECT

SUNLIGHT OR WHERE EXPOSED TO FREEZING

TEMPERATURES OR RAIN.

TDS Monitor

Install next to processor

TDS MONITOR

MODEL SM-1

o

ON/OFF

Blending Valve

BWS175 Simple Install Guide 5

Mount the system with the Pre-Installed Drain Line

(1/4” black), Bypass Assembly (3/8” red), and Blend

Valve Assembly (1/4" blue) as shown below.

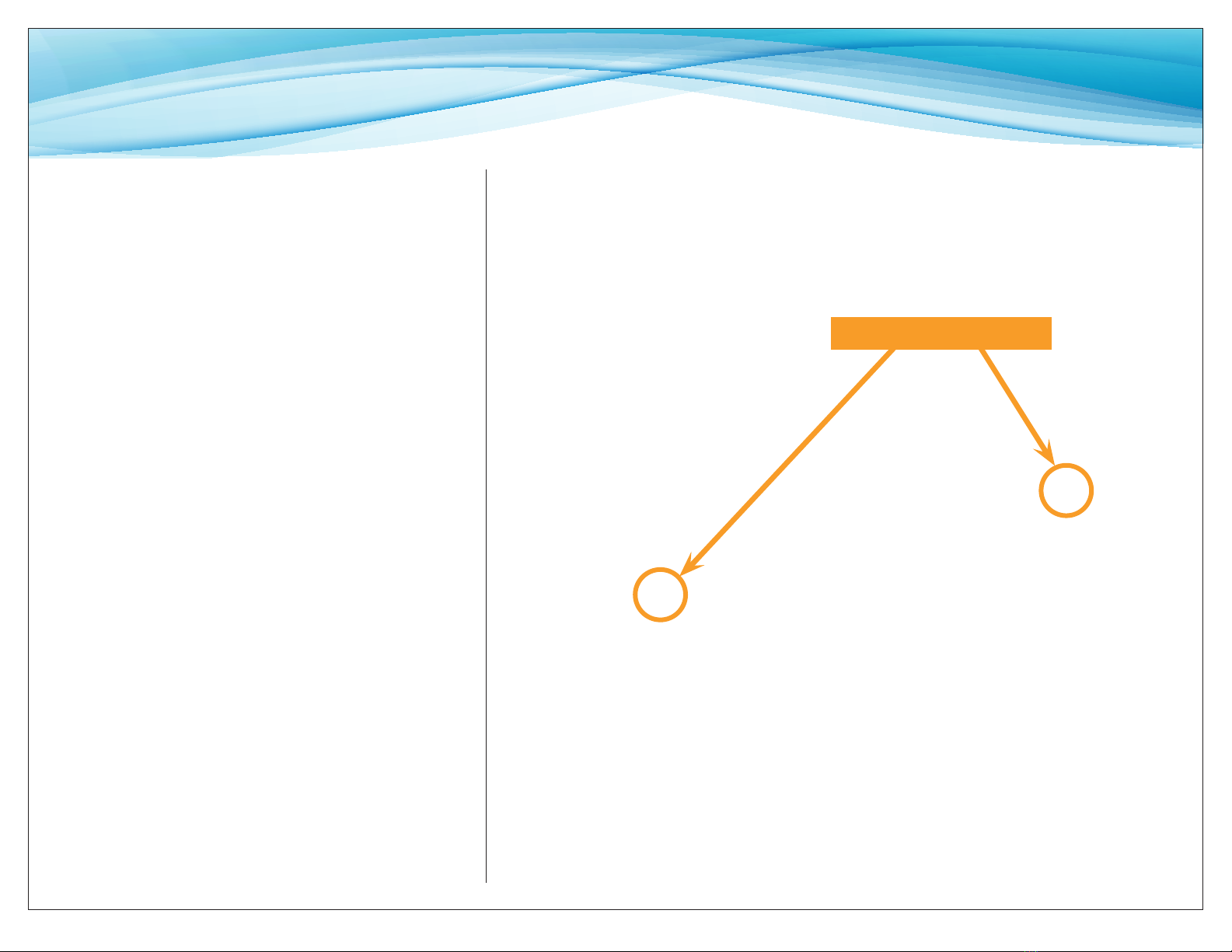

Step 1

Attach the system with 2 screws (user supplied) through the attachment keyholes shown

below. Use anchors or attach directly to studs. Be sure to allow at least 3” clearance

below cartridges for removal.

vMount Processor

Use Keyholes in Bracket

BWS175 Simple Install Guide 6

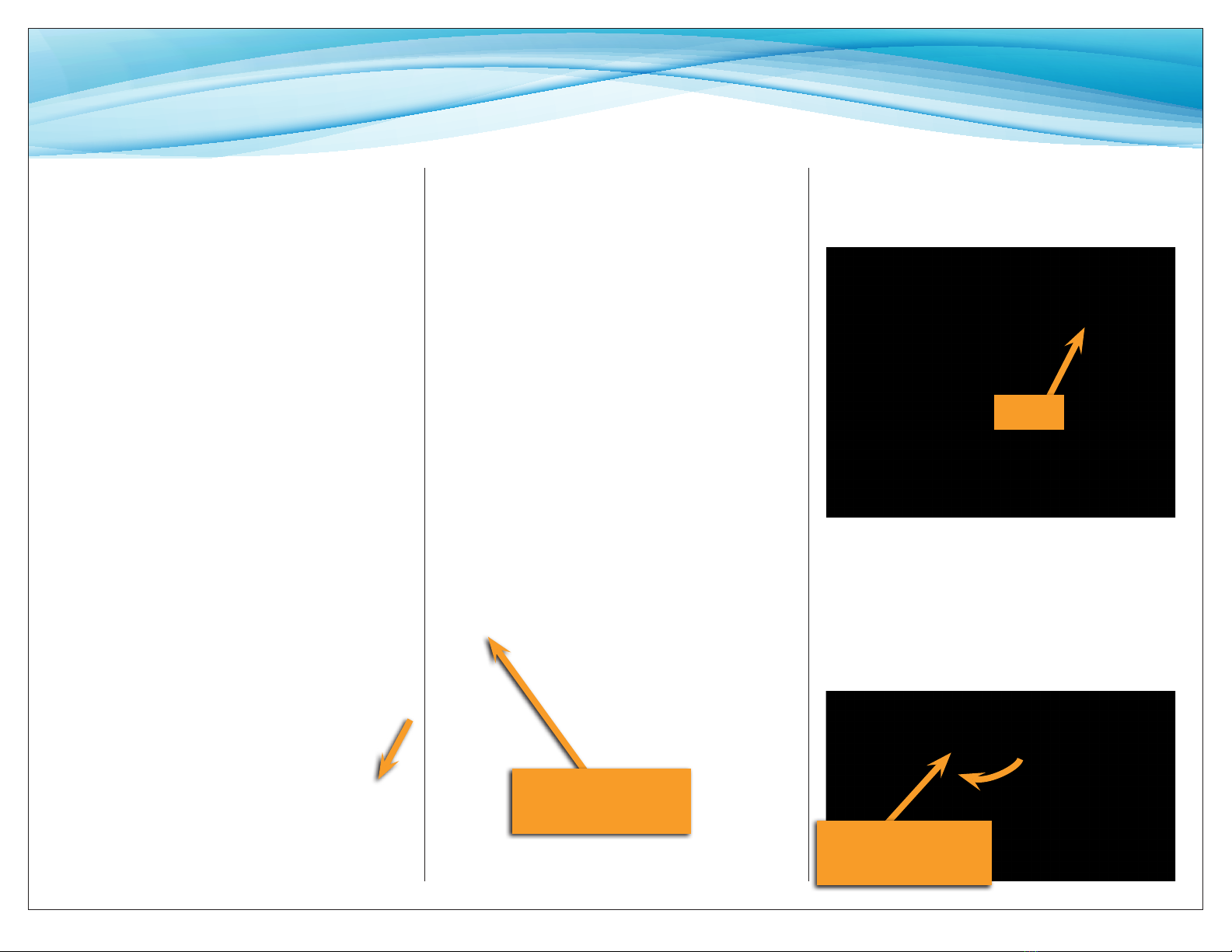

Step 2a

Insert the AMS-QT15 Membrane into the center

head and rotate it to the right 1/4 turn to lock.

Step 2b

Remove the plug from the tting at the bottom

of the Membrane and insert the end of the

black tubing coming from the lower left part of

the Permeate Pump.

Attention: Warranty will be void if

this step is not performed properly.

Step 3

Insert and lock the CTO-Q10 Cartridge into the

Pre-Filter Head as shown.

NOTE: The pre-lter head has a built-in shut o

valve. When the lter is removed, water will not

ow. When the lter is installed, water will ow

to the system.

vInstall Membrane

vInstall the Pre-Filter

...To Bottom

of Membrane

BWS175 Simple Install Guide 7

v

Make Drain Connection

vMake Feed Connections

Step 4

Route and connect the loose end of 1/4” black

(DRAIN) tubing coming from Permeate Pump on

processor to a suitable drain; cut to length and

fasten to the wall and at the drain connection.

(Some locations may require an approved air

gap. Optional OptiPure Air Gap available, part

number: 164-89905)

Step 5a

Install the Feedwater Adapter (from the

installation kit) into the user-supplied 1/2”

Feedwater Supply Valve. (Do not over-tighten.)

Step 5b

Connect a piece of 3/8” green tubing to the

Feedwater Supply Valve. Connect the other end

to the Feedwater Inlet on processor.

Step 6

Install the Tank Valve – hand tighten. Cut a piece

of 3/8” tubing 1 1/2” to 2” long and install the

3/8” Tee as shown above. Ensure the Valve is

CLOSED.

Step 6

Feedwater Adapter

(Supplied)

v

Install Tank Valve

and Tee Assembly

Tank Valve in

CLOSED position

BWS175 Simple Install Guide 8

Follow instructions below and proceed to next step.

Step 7a

Connect a piece of 3/8” blue tubing to the

Optimized Water Fitting from the processor.

Connect the other end to the Tank Tee as

shown below.

Step 7b

The remaining connection at the Tank Tee is the

Optimized Water Outlet. Connect a piece of 3/8”

blue tubing to the Tank Tee. This will later be

the water supply connection to downstream

equipment.

Do not connect to equipment at this

time.

vMake Optimized Water Connections

Step 7a

Step 7a

Step 7b

BWS175 Simple Install Guide 9

vMake TDS Monitor Connection

Installing the TDS monitor.

Step 7c

Install TDS Monitor next to the RO processor

using sticky tape with Velcro (supplied with

monitor). Connect TDS Probe to 1/4" tee

fitting located right before Optimized Water

to Storage Tank fitting connection.

Step 7c

TDS Probe

BWS175 Simple Install Guide 10

Step 10

Open the Feed Valve. Allow water to ow to

drain until all air is purged from the system.

Close the Feed Valve after ushing.

Note: During normal operation the water ow

alternates between the optimized water line

and the drain line. You will notice that the

water ow pulses when the system is making

water.

Step 9a

Ensure Bypass Valve is CLOSED.

Step 9b

Ensure Tank Valve is CLOSED.

Step 8

Temporarily route the 3/8” blue tube from the

Optimized Water Outlet on the Storage Tank

Line to a drain or sink.

Step 9b

Step 10

Step 9a

v

Flush the System

Step 8

BWS175 Simple Install Guide 11

vSet Blending Valve & Connect to Equipment

Step 11a

Route and secure the 3/8” blue tube from the

Optimized Water Outlet on the Tank to the

downstream equipment connection.

Step 11b

Make the connection to the equipment.

Connect ONLY the treated/steam water

connection at the equipment. Do notconnect to

the drain/condensate supply.

Optimized Water

to Equipment

Step 11ab Step 12

Tank Valve in

Open position

Step 12

Turn the Tank Valve to the OPEN position. The

installation is complete and the system is ready

to be placed into service.

Step 11

Set blending valve to desired optimized

water TDS:

•Close the Storage Tank valve and

run optimized water line to drain

temporarily.

•Push the "on/off" button on the

water quality monitor. It will display

the optimized water's TDS (total

dissolved solids) in PPM (parts per

million).

•To increase Optimized water TDS

turn the blending valve knob

counter-clockwise, this will increase

the amount of filtered water

blending with the re-mineralized RO

water.

•To decrease Optimized water TDS

turn the blending valve knob

clockwise, this will decrease the

amount of filtered water blending

with re-mineralized RO.

•Once the desired TDS is obtained

allow the system to run for several

minutes periodically checking the

TDS. Make smaller incremental

adjustments as necessary until the

TDS " target" is achieved.

BWS175 Simple Install Guide 12

If a water supply to downstream

equipment is immediately

needed, the storage tank can be

quickly lled.

v

Place in Service

Step 13

OPEN the Feed Suppy Valve and check for

leaks. Allow time for the tank to ll before

using connected equipment (this could take 30

minutes to several hours depending on the

tank capacity).

Step 13

v

Quick Tank Fill

Open Bypass

Simply OPEN the Bypass Valve and un-ltered

water will ow directly into the storage tank.

When the tank is full, or a desired level is

reached, CLOSE the Bypass Valve. The system is

now in normal operating mode and the

optimized water will flow to the tank.

IMPORTANT: Do not leave the system in

bypass. This could result in damage to the

downstream equipment.

BWS175 Simple Install Guide 13

Open Closed

vOperation

The system operates normally when water,

under pressure, is supplied to the system.

Typical filter replacement is every 6 months

(CTOS-Q10 and ILMA-10.14). Typical

membrane replacement is every 24 months

(AMS-QT10) or less, based on water quality.

EMERGENCY BYPASS

In the event the water supply or pressure to

downstream equipment becomes inadequate

OPEN the Built-In Bypass Valve and resume

normal use of equipment. When finished using

equipment return the Valve to the CLOSED

position. DO NOT leave the system in bypass

mode for prolonged periods of time.

IMPORTANT: Leaving the system in bypass

could cause damage to downstream

equipment. If the problem persists contact

your OptiPure dealer for assistance.

Step 1

Close Feed Water Supply Valve.

OR

Be sure Bypass Valve is closed and turn

pre-lter cartridge 1/4 turn to the left .

Step 2

Close the Storage Tank Valve.

Tank Valve in

CLOSED position

vSHUT OFF WATER TO SYSTEM

The water is now shut o and the system is

ready for lter or membrane replacement or

other maintenance.

To return to normal operation reverse these

steps.

Table of contents

Other Aquion Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Clean Water Systems

Clean Water Systems Pro-Ox 5900-BT-AIR Series Installation & maintenance guide

Brita

Brita WD 3030 manual

BWT

BWT Quick & Clean instruction manual

Grunbeck

Grunbeck MRA25 Operation manual

King Industrial

King Industrial KDCF-8300 instruction manual

Grunbeck

Grunbeck desaliQ:BA Series Operation manual