Berkefeld TWA 6 User manual

OperatinginstructionsTWA6

Please keepforfutureuse!

Contents

IDescription TWA6

II Standarddosing plan

“BerkefeldEMERGENCYEXERCISE and ACTION(full)SDP“

III Short operating instructionsTWA6

IVOperating instructionsTWA6

VTrouble-shooting

VI Maintenanceworkand repairwork

VII Operating instructionsand sparepartslistsforaggregates

VIII Loading list, loading plan

IDescriptionTWA6

Process descriptioningeneral

The Berkefelddrinking waterpurifierservesforprovision ofhygienicallyperfect,

crystal-cleardrinking water.

Everynormallypolluted and germ-contaminated surfaceorwell watercan be

treated. The unit isnot suitablefordesalination of brackishorsea water.

Berkefelddrinking waterpurifiersoperateacc. tothe precoat filtration process.

The rawwaterfromrivers,lakesorwellsispumped into4pre-treatmenttanks (8

m³each)bymeansofamotorpumporelectr.pump.Inthe singlerawwatertank

the chemicalsacc.tothe BerkefeldEMERGENCYEXERCISE orACTION SDP

(standard dosing plan)areadded.The addition iseffected infourstepswith

corresponding retention time.The waterpre-treated thiswayissupplied tothe

precoat pumpviathe surfacesuction deviceand viathe rawwatercollector.

Inthe beginning ofthe filtering process acertainquantityoffiltermaterial(Berkesil

KE)isfed tothe precoat filterbythe precoat pump. Bythe following pre-treated raw

waterstreamthe filtermaterialisprecoated tothe specialBerkefeldfiltercandles

located inthe precoatfilter,and thereitformsthe filtering layer.Flowdirection in

the precoat filterisupwards(see attachment 6).

Afterthe filtration the required chlorine value inthe purewaterisadjusted by

meansofachlorine dosatorbeing connected insubsequentposition.The

chlorinated purewaterissupplied tothe purewatertank,and afteraretention time

itissupplied asdrinking watertotanks ordistributorsbyapurewaterpump. Bythe

secondarychlorination are-infection isprevented.

Withincreasing pollution ofthe filterlayerthe filterhead loss increases.If afilter

head loss ofabout3barisreached,the filterprocess isinterrupted and the plant is

backwashed.The flowdirection inthe precoatfilterisnowdownwards.After

backwash, newfiltermaterialisprecoated and the filterprocess startsagain.

The purewaterreservoirfacilitatesshort-termoutputpeaks ofabouttwicethe

capacityof the plant.

Sincedrinking watertreatmentisofutmostimportanceitisadvisableto

followtheseinstructionsexactlyand topractiseall processesdescribed in

practiceoperation withstarting and stopping the operation repeatedly.

Areliableoperation can onlybe expected ifthe manualoperation ofthe

planthasbeen thoroughlytrained on exercisesand the operating staff is

well acquainted withthe functioning of the plant.

The exercises must be repeated everythree monthssincean absolute

reliabilityinoperating suchappliancesisonlyguaranteed byconstant

repetition.

Attention

!

II Standarddosingplan

“BerkefeldEMERGENCYEXERCISE andACTION(full)SDP“

1.The BerkefeldSDPisused incaseof disasterabroad withunknownwatersand -in

reduced extent -forexercises.

2.The EMERGENCYEXERCISE SDPisused withextremelystronglypolluted,

unknownwatersorincaseof chemicaldisasters.

3.The ACTIONSDPisexclusivelyused incaseof defence.

The respectiveSDPishandled acc. tothe timeand dosing schedule.

Use ofthechemicalsacc. tothedosingandtimeschedule

Required chemicalsforthe TWA6rawwaterpretreatment per8m3tank

1.HTHchlorine: Dissolve800 g(100 g/m3)in10 litresof waterand fill it withthe first

rawwaterintothe tank. Filling time+10 minreaction time

1.2Afterreaction time, add 800 g(100 g/m3)ferricchloride, dissolved inabucket,

evenlydistributed intothe tank. (Payattention tothe carbonatehardness!)Reaction

time15 min

2.Inthe meantimeassemblethe othertanks, start filling and addition of chemicalsas

described under1.

3.Afterreaction time, add 1600 g(200 g/m3)activated carbon, mixintwobucketsand

add intwostepswithcontinuousintensivestirring. Reaction time20 min

4.Afterreaction time, adjust pH-value. When required, add about 400 g(50g/m3)

calciumhydroxide, dissolved inabucket, add intothe tankevenlydistributed.

Sedimentationapprox. 30 min

5.Measuring of pH-value and chlorine content

Required values:pH-value between 7.0and 7.5

Chlorine below1.0mg/l

Timerequired intotal: filling time+90 min

Afterthistimethe discharge fromthe first rawwatertankviathe precoat filteris

possible.

HinweisfürdenBenutzerdieserDatei:

Einheitsdosierplan unter

O

allgemei

bedienun

TWA6alt, englisch

Zusatzinfos

bfedp.xls

einheften.

III ShortoperatinginstructionsTWA6

1.Filling the rawwaterpumpwithrawwaterand installation ofarawwatertankincl.

all suction and deliveryhoses.

2.Preparethe required chemicalsforthe TWA6per8m3tank.

2.1Dissolvechlorine acc. Tothe corresponding dosing plan inapprox. 10 litresofwater

and fill intothe tankwiththe first water.

2.2Keep the reaction time.Then dissolveferricchloride acc.tothe dosing plan in

approx. 10 litresof waterand add intothe tank. Keep the reaction time.

3.Inthe meantime,install the otherrawwatertanks and startwithfilling and addition

of chemicalsasdescribed inpoint 2.

4.Addition ofactivated carbon acc.tothe dosing plan (inapprox.10 litresofwater),

stirwell, keep the reaction time.

5.AfterpH-measuring,adjustthe pH-value byaddition oflime(inapprox.10 ltrs.of

water), keep the reaction timeand allowsettling forabout 20 -30 min.

5.1Aftereachaddition of chemicalsone hastostirvigorouslyforabout 5min.

6.Installation of the precoat pump:

6.1Prepare2kgBerkesil KE withabout 10 ltrs. of treated waterfromthe first rawwater

tank(distributed totwoprecoatbuckets,additionallyprovide anotherbucketof

waterforrinsing).

6.2Deaeratethe precoatpumpviarawwatercollector,4-waysuction valveand

precoat hose, precoat (approx. 4-5m3/h; throttleslide valve).

6.33-waytap ison position “Filtration“.Onlyswitchoverto“Circulation“ifthe water

drainsoff the purewateroutflow.

6.4Operate“Circulation“forabout5-7min.Then switchovertofiltration.Rinsethe

hosepipesincl. the waterinflowpipe withpurewaterforabout 30 sec.

6.5Then switchto“Circulation“and hang the purewaterinflowpipe intothe covered

purewatertankand install the chlorine dosator.Nowswitchto“Filtration“again

and operatethe plant withmax. 6m3/h.

7.Preparechlorine forthe chlorine dosatorasfollows:

Mixapprox.90 gHTHchlorine withapprox.9ltrs.ofwater,stirwell and fill this

solution intothe chlorine dosator,deaerateand adjusttocapacity(l/h=1mgCl2/l).

Adjust withneedlevalvebelowthe flowmeter.

8.If the precoatfilterreached adifferentialpressureofapprox.3bar(difference

between the manometersbeing installed beforeand afterthe flowratemeter),the

plant hastobe backwashed asfollows:

9.The backwashofthe precoatfilterhastobe carried outwiththe purewaterpump

and the purewaterviathe connection “purewater".Quenchforaboutsixtimes

(about three timespertank), then precoat againviarawwater.

IVOperatinginstructionsfor

Berkefelddrinkingwaterpurifier

TWA6

Capacity6m3/h

Contents

IV1. Colourof hosesand pumps

IV1.1. Installation, pumps, hoses, rawwatertank

IV1.2. Operation/pretreatment unit

IV1.3. Precoat filter

IV1.3.1. Purewatertankand purewaterdistributor

IV1.3.2. Operation of the precoat filter

IV1.3.3. Backwashof the filterplant

IV1.3.4. Backwashprocess of the precoat filter

IV1.4. Chlorine dosator

IV1.5. Checks during operation

IV1.6. Dismounting of the unit and storage

IV1.7. Important information

IV1.Colourofhoses andpumps

All hosesand pumpsarecoloured.

All red hosesand pumpsarerawwaterconducting plant componentsand mayonly

be coupled withthiscolourmarking.

All whitehosesand pumpsarepurewaterconducting plant partsand mayonlybe

coupled withthiscolourmarking.

All black hosesaresludge waterconducting plant partscan be coupled withred

hosesforextension if required.

Red and whiteplant partsmust not be coupled.

The circulation hoseisthe onlyhosewhichiscoloured red-

whitebecausethisconductspurewaterand pretreated raw

water.

IV1.1.Installation, pumps, hoses, raw watertank

Open supporting ring (see annex1)insuchawaythat the supporting ring hinges

showtothe bottom. Put 8supportsintothe supporting ring and protect withthe

chains. Bring the supporting ring asnearaspossibletothe discharge point.

Takerawwatertankfromthe packing (packing see annex3), unfoldand suspend

intothe supporting ring insuchaway, that the outflowhoseshowstoadischarge

possibility(pit, at running watersbelowthe waterdischarge point etc.).

Suspend discharge hoseintothe supporting ring. Install the otherthree rawwater

tanks inthe samewayand placeasnearaspossibletothe first.

Assemblethe suction sets(see Attachment 2)correspondinglyand couplethemto

the rawwatertanks frominside. Suspend suction setswiththe end support intothe

supporting ring.

Attention

!

Install the rawwaterpumpasclosetothe intakeplaceaspossible. Connect one or

tworawwatersuction hoseswithstrainer, protectivebasket and plasticfloat with

chainon suction side. Securethe suction valveand hoseswithan arrestercable.

Hang the rawwaterinflowpipe intothe first rawwatertankand connect it tothe raw

waterpumpwithacorresponding numberof rawwaterpressurehoses. The raw

waterinflowpipe isalternatelyhung intoall rawwatertanks whicharethen being

filled.

Nowthe fourrawwatertanks havetobe coupled tothe rawwatercollectorwith

additionalrawwatersuction hoses. It hastobe checked that all fourball valvesof

the rawwatercollectorareclosed.

IV1.2Operation/pretreatmentunit

The rawwaterpumpcan be started acc. tothe operating instructionsforfilling of

the first rawwatertank(see VII).

Whilethe first tankisbeing filled, one preparesthe treatment chemicals(chlorine,

ferricchloride, activated carbon, lime)acc. tothe respectivestandarddosing plan

inthe 17 lbucketsfilled withrawwater. Takecarethat the chemicalsarenever

added tothe rawwatertanks inundissolved condition. Theyshouldalways be

dissolved and stirred ina17 lbucket filled withpurewateror, if not otherwise

possible, withrawwater.

Firstfill inthewater(approx. 10 l), thenadd thechemicals.

If the waterlevelinthe first tankhasreached the knee at the rawwaterinflowpipe,

one addsthe first chemical(chlorine). One proceedswiththe otherchemicals

(ferricchloride, activated carbon, lime)acc. tothe standarddosing plan. Eachtime

adding chemicalsone hastostirvigorouslywiththe paddlesothat the chemicals

arewell distributed. (If available, the stirring can alsobe carried out withan air

pipe.)

If the rawwatertankisfilled, one throttlesthe rawwaterpumpand hangsthe raw

waterinflowpipe intothe next rawwatertank. Hereone proceedsjust aswiththe

first rawwatertank. The sameappliestothe thirdand fourthrawwatertank.

Aftereachfiltration of arawwatertankasludge layerremains. The newfilling can

then be carried out asdescribed inpoint IV1.2(useof the contact sludge). After

about 5-10 newfillingsthe sludge isdrained off the tank.

IV1.3Precoatfilter

The precoat pumphastobe connected withthe four-waysuction valve. Arawwater

suction hosehastobe connected fromthe rawwatercollectortothe four-way

suction valve(C-Storz).

The precoat hosewhichis2mlong and whichisequipped withone Storzcoupling

Donlyhastobe connected tothe four-waysuction valve. Onthe otherside of the

four-waysuction valvethe circulation hose(red-white, length5or10 m)hastobe

connected withthe circulation outlet (three-waytap)of the precoat filter.

Ondeliveryside, a5m(or2x5m)rawwaterpressurehosehastobe connected to

the precoat pumptothe rawwaterinflowof the precoat filter. The rawwaterinflowis

always at the flowratemeterof the precoat filter.

The distancesshouldbe asshort aspossible(5mcirculation hoseand 5mraw

waterpressurehose). The precoat filtershouldbe installed ashorizontallyas

possiblesothat aproperdeaeration can be effected.

The sludge hose(onlyequipped withone Storz-Ccoupling)iscoupled tothe Storz-

Coutlet of the precoat filter. Anextension can be effected bymeansof red suction

hoses.

The purewaterpressurehoseiscoupled tothe purewateroutlet (three-waytap)of

the precoat filter.

Takecarethat the purewaterhosesarenot thrownintothe dirt

asthisisthe drinking waterside.

At the end of the purewaterpressurehosethe chlorine dosing isconnected and

supplied tothe covered 8m³purewatertankwithafurtherpurewaterpressure

hoseviathe purewaterinflowpipe.

The purewaterinflowpipe tothe purewatertankisnot hung intothe tankbut

attached tothe outside of the purewatertanksothat the first purewatercan be

discharged (rinsing of the purewaterpipes-about 30 sec).

Installation of the chlorine dosatoronlyafterthe purewaterside hasbeen rinsed.

IV1.3.1Purewatertankandpurewaterdistributor

The purewatertankhastobe installed just asthe rawwatertanks (see point IV1.1;

packing see Attachment 3). Afterhanging-inof the tankintothe supporting ring, the

support forthe coverhastoset intothe tank, braced bya“spider” withthe

Attention

!

supporting ring and the coverhastobe laidon the bracing (see annex1). Bracethe

coverwiththe cordsat the supportsof the supporting ring.

Payattention toutmost cleanliness at the purewatertank.

Then on suction side the purewaterpumpiscoupled withapurewatersuction hose

and agatevalvetothe purewatertank(StorzC). Ondeliveryside of the purewater

pump, acorresponding purewaterpressurehoseisconnected towhicheithera

purewaterdistributor, atapping pistolorthe socket forthe tankfilling (truck)can be

connected.

IV1.3.2Operationoftheprecoatfilter

The rawwaterpretreated inthe rawwatertankcan nowbe supplied tothe precoat

pumpbyopening the first ball valveat the rawwatercollector. Open mainball valve

and precoat ball valveof the four-wayvalve, deaeratethe precoat hoseand fill both

precoat bucketswithapprox. 10 lof water. Thisisalsothe easiest waytodeaerate

the pump. Then closebothball valves.

Then add the precoat materialtobothbuckets(2kgBerkesil KE, 1kgperbucket).

Anotherbucket withpretreated waterisrequired forwashing downthe mixed precoat

material. The precoat materialhastobe well stirred and wetted withawooden stirrer.

At the beginning of the precoat process the slide valvebeing placed beforethe flow

ratemeterof the precoat filterhastobe opened alittle(2-2½rotations)sothat the

precoat process can be carried out withacapacityof approx. 4-5m³/h.

The deaeratorsof the precoat filterareopened, the sludge discharge ball tap isclosed

and the 3-way-tap isinposition „filtration“. The precoat pumpisstarted, the ball tap of

the 4-waydeviceat the precoat hoseisopened and the precoating mass issucked. If

thisprocess isfinished, the ball tap of the 4-waysuction deviceat the precoat hoseis

closed and the mainball tap of the 4-waydeviceisopened forrawwaterfeed.

The circuit ball tap of the 4-waydeviceisalways open. The pumpconstruction allows

that the precoating process can be carried out withlowmotorspeed (fuelsaving). As

soon aswaterflowsout through the deaeratorsof the precoat filter, theyhavetobe

closed. If the waterflowsthrough the purewaterpipe at the precoat filterafterashort

time, the 3-waytap hastobe turned toposition „circuit“.

Attention

!

The deaeratorshavetobe opened fromtimetotime, sothat entered aircan escape.

Afterapprox. 5-7min. circuit operation the 3-waytap isbrought toposition „filtration“

again.

The first water(approx. 30 sec.)shouldbe used forrinsing of the purewaterpipes.

Onlyhereafterthe purewaterinflowpipe isput inthe purewatertank. The full capacity

of 6m³/hisadjusted withthe slide valvepreceding the flowratemeterof the precoat

filter. The pumppressurebeforethe flowratemetershouldbe adjusted to1barabove

filterresistancewiththe adjustment of the pumpspeed.

The minimumcapacityshall not fall below1000 l/h. The filterloss of head isreadable

at the pressuremanometersof the precoat filter. The filterloss increaseswith

increasing pollution. The adjusted capacityreduces, sothat readjustment hastobe

carried out at the slide valve. If afilterloss of head of approx. 3barisreached at a

capacityof approx. 2m³/hand at full pumpcapacity, the filtration process hastobe

interrupted, asotherwisethe plant operatesuneconomically.

IV1.3.3.Backwashingofthefilterplant

During backwashing, the precoat filterisbackwashed shock-wiseinreverse

direction, i.e. downwards. Byshocking inbatches(see annex4)the solidfilterlayer

isseparated fromthe cartridgesand flushed out through the sludge outflowhose.

The precoat filtermust be backwashed withpurewater.

IV1.3.4.Bachwashingprocess oftheprecoatfilter

Turnthe 3-waytap of the precoat filtertoposition „circuit“. Closeslide valve

preceding the flowratemeterof the precoat filter. Switch-off precoat pump. Close

mainball valveof the 4-wayfitting. Open ball valveof the sludge outflowhoseat the

precoat filter. Open de-aeration tapsof the precoat filter. Uncouplecirculation hose

at the circulation outlet of the precoat filterand wait until the precoat filteris

emptied. Then connect the circulation hoseagain.

Closede-aeration tapsand ball valveof the sludge outflowhose. Couplepurewater

pumpwiththe purewaterpressurehose(whichiscoupled withthe purewateroutlet

of the precoat filter). Set 3-wayvalveof the precoat filtertoposition "Filtration" and

start purewaterpump. The pumphastobe operated withfull capacity. If the slide

Attention

!

valveand ball valveareclosed, the pressuremanometeron precoat filterside

showsapprox. 3-4bar. The ball valveat the sludge outflowhoseisopened

suddenlyand remainsopen forapprox. 5sec., then closeslowly. Thisprocess must

be repeated 6times. The rinsing waterflowing off the sludge outflowhosemust then

be clear. The sludge discharge hosemust be heldon toduring the backwashing

process orit hastobe tied-up.

Switch-off purewaterpump, let ball valveof the sludge outflowhoseopen, open de-

aeration valvesand uncouplecirculation hoseat the circulation outlet and holduntil

precoat filterisempty.

The precoat filterisbackwashed and can be started againasdescribed underitem

IV1.3.2.

Completebackwashing shouldnot exceed 4-6min.

IV1.4. Operatinginstructions

for

chemical displacementdosatorLC9

for

BerkefelddrinkingwaterpurifierTWA

Contents

IV1.4.1. Purposeof the unit

IV1.4.2. Working method

IV1.4.3. Addition of chemicalsinproportion tothe watersupply

IV1.4.4. Preparation of chemicalsolution

IV1.4.5. Commissioning

IV1.4.6. Shut-down

IV1.4.7. Chlorine definitions

IV1.4.1.Purpose oftheunit

The unit isused fordosing of watertreatment chemicalsinmobiledrinking water

purifiers. Installation can be carried out preceding orafteraBerkefeldprecoat filter

plant bycoupling the unit withthe connectionsbetween 2hoses. Dosing iscarried

out continuouslyintothe treated purewater.

IV1.4.2.Operationmethod

The dosatoroperatesaccording tothe back pressuredisplacement process, i.e. a

firmlyinstalled jamscreen isinstalled between twoconnectionsinthe mainwater

flow, bywhichdifferent pressureratiosariseinthe twoby-pass connections(∆p).

∆ p

_____é___________ê__

P1P2

____________ ____________

Bythisthe required quantityof waterissupplied tothe displacement tankviathe

motivewaterpipe withflowmeterand adjusting valve. The samequantityof

chemicalsolution isdisplaced and pressed intothe mainwaterflow. The adjustment

of the chemicalquantitytobe added iscarried out byan adjusting valveat the flow

ratemeter. The chemicalsolution isinabag, whichishoused inthe displacement

tankand whichfillsit out completely.

Annex5showsthe dosing unit. It consistsof the following parts:

01 Dosing tank(displacement tank)

02 Displacement bag

03 Filling and dosing connection

04 Mainconnections(retarding disc pipe)

05 Flowmeterwithadjusting valve

06 De-aerator

07 Drain

including the required connection pipes.

IV1.4.3.Chemical additioninproportiontothewatersupply

The quantityof the chlorine added isdetermined bythe corresponding responsible

man ineachsinglecase. If no instruction hasbeen given, werecommend toadjust

chlorination of the waterhaving achlorine excess of

0.5-1mgCl2/l.

The following mentioned common chlorinouschemicalsareused:

1.Chlorine bleaching solution chlorine contentsapprox. 12 %

(sodiumhypochlorite)(takecareon temperature, gasevolution)

2.Chloraminchlorine contentsapprox. 28 %

3.HTH-chlorine (C8powder) chlorine contentsapprox. 60 %-65 %

(calciumhypochlorite)

If achlorine addition of 1mg/lisdemanded and an operation of the drinking water

purifierwithacapacityof 6m³/h, the chlorine quantitytobe added perhourwould

be 6gCl2/h. The flowratemeterhasameasuring range of 0.5-5.4l/h.

The dilution ratioof the chemicalsolution hasbeen chosen insuchawaythat a

chlorine quantityof 1mg/lisadded, if aflowrateof 1l/hisadjusted at the control

valve. The ratiobetween adjusted flowrateand dosing quantityremainsthe sameat

eachadjustment.

Forexample: demanded chlorine addition of

0.5mgCl2/l=0.5l/hat adjusting valve

or

2.5mgCl2/l=2.5l/hat adjusting valve

If the drinking waterpurifierisoperated withalowercapacity, the dosing capacity

reducesinthe sameratio(∆p).

IV1.4.4.Preparationofthechemical solution

Wearprotectionclothes!

When preparing the solution, 9lpurewaterand the chlorine media(corresponding

tothe concentration)inthe following mentioned quantitieshavetobe stirred well.

Chlorine bleaching solution 12 %450 g

Chloramin28 %190 g

HTH-chlorine 60 %90 g

Afterremovalof the screwing, the prepared solution isfilled (funnel)intothe

chlorine solution bag. The tankdeaeratormust be opened.

Beforerefilling the emptydosator, the motivewaterhastobe discharged through

the tankdrain.

Beforecoupling the dosatorintothe purewater, the filterplant isswitched againto

circuit.

IV1.4.5Commissioning

During commissioning of the dosator, the following pointshavetobe carried out

exacty:

1.Closechlorine solution gatevalveorseparatequick-coupling

respectively

2.Closetankdrain

3.Open adjusting valvecompletely

4.Open tankde-aeration until motivewaterflowsout

5.Closetankde-aerator

6.Open chlorine solution gatevalveorconnect quick-coupling respectivelyand

wait until chlorine solution flowsfromthe chlorine solution bag through the

transparent overflowpipe

7.Adjust controlvalvetodemanded value

Attention

!

8.Controlfunction of the dosing unit at the controlvalveand overflow

pipe

If the outflowforfilling of atankerhasbeen elevated, the dosing quantityhastobe

changed. Re-adjustment at controlvalveisabsolutelynecessary.

If no purewaterisgiven and the filterplant isswitched tocircuit, the controlvalve

and gatevalvehavetobe closed orthe quick-coupling hastobe separated

respectively. The dosatorisswitched off.

The dosatorhastobe uncoupled during backwashof the

precoat filter.

IV1.4.6.Shut-down, storage

Aftershut-downthe plant hastobe discharged thoroughly. Open all valves, sothat

the watercan flowout fromthe displacement tank.

Especiallytheflow meterhas tobeprotectedagainstfrostandhas tobe

storedintheboxforaccessories (blow throughatopenedadjustingvalve).

Then unscrewthe filling socket and pourout the residualchemicalsolution.

It isnot allowed totakethe full chemicalbag fromthe tank,

asit wouldcrack fromitsholding.

Attention

!

Attention

!

IV1.4.7.LEAFLET

“ChlorineDefinitions“

„Effectivechlorine“(total chlorine)

The sumof the elementarychlorine (free effectivechlorine), availableinthe waterat

the point of timeof analysisand itssterilizing acting compounds(bound effective

chlorine)iscalled „effectivechlorine“(totalchlorine).

„Free effectivechlorine“

Chlorine, whichisavailableinawaterinformof dissolved elementarychlorine (free

chlorine), hypochlorousacidorhypochloridions, iscalled as„free effective

chlorine“.

„Boundeffectivechlorine“

Chlorine, whichisavailableinawaterinformof oxidizing acting chlorine substitution

compounds(anorganicand organicchloramines)iscalled as„bound effective

chlorine“.

Calculationas follows:

totalchlorine

-free effectivechlorine

=bound effectivechlorine

=====================

IV1.5.Controlsduringoperation

All unitsoperated withfuelmust be checked at regularintervalson fueland oil level

during operation, sothat aperfect operation isguaranteed. If the precoat pump

wouldfail due toaleakage of fuel, the completebackwashing and precoating

process wouldhavetobe repeated.

The samesituation wouldoccurwiththe electricalpumps. The current generators

havetobe checked continuously.

The quantityflowratemeterhastobe controlled continuouslyduring operation of

the precoat filter. Should-foranyreason -the precoat filtersuck airorshouldthe

precoat pumpfail, one wouldrecognizethisat the float of the flowratemeterand

one couldswitchthe 3-waytap to„circuit“, sothat the purewatercannot be

polluted.

The flowratemeterof the chlorine dosatoralsohastobe controlled continuously,

sothat no excess orless dosing can occur.

The motorpumpsand the electricalpumpsmust inno case

operateindrycondition. Thiswouldcauseadefect at the

axialfacesealorstuffing box.

IV1.6.Dismountingofunitandstorage

Thoroughlydrainthe plant afterbackwashing, withspecialcarethe flowmetersat

the filtertankand at the dosator(frost!).

Let all slide valvesopen, sothat the airhasfree entryintothe inside of the tanks.

Connectionsprovided withblind couplingstobe closed onlyduring the drive, open

againinthe depot.

The pumpshavetobe thoroughlydrained beforepacking. Open the tap orscrewat

the bottomof the casing and incline the pumpcorrespondingly(frost!).

Beforepacking, all plant partshavetobe cleansed. If athorough cleaning cannot

be carried out at site, it hastobe repeated inthe depot orat anysuitableplace.

Beforepacking the rawwaterand purewatertanks havetobe hung up at the small

rings. the rawwatertanks can be flushed withpurewater, then dryand folded acc.

tothe attached plan (Attachment 3).

The plant isresistant tofrost, provided that all plant partshavebeen thoroughly

drained.

The foldabletanks aremade of rot-proof, artificialmaterialcoated textile. The hose

materialisrot-proof aswell. Despitethis, hosesand tanks shouldbe packed only

afterairdrying. All plant partshavetobe checked on completeness and readiness

foruseaftereachuse.

Attention

!

IV1.7.IMPO RTANTNO TES

If the first pre-treatment tankispumped-off, one hastochange-overtothe second

one intime. Thisiscarried out byopening the ball valveat the rawwatercollectorof

tank2and onlyafterthat the ball valveof tank1isclosed. The plant can be

operated continuously.

It isnot allowed tointerrupt the started filtration, asthe filterlayerwouldfall fromthe

filtercartridgesif the waterflowisinterrupted. If, however, during orshortlyafterthe

commissioning the waterflowisinterrupted due toanyreason, the unit can be

started again(circuit approx. 5-7min.)

The filtermaterialfallen fromthe cartridgesembeddsbynewstart. If the plant had

alreadybeen switched tofiltration, one hastooperateagainincircuit during restart.

But if the plant had been inoperation formorethan 1hour, backwashing of the filter

materialhastobe carried out aswell asnewprecoating.

The operation timeof the plant stronglydependson the qualityof the rawwaterin

the pretreatment tanks. Incaseof poorwatersorat averybad flocculation, the plant

can showalreadyafter1houradifferentialpressureof 3barand hastobe

backwashed. If the pretreatment isverygood, running timesof 5-7hoursand more

can be reached at full capacity.

Operationinterruptions:

If no purewaterdischarge isrequired forashort period, i.e. for30 min., the plant

capacitycan be lowered bythrottling the motorpumptoapprox. 1m³/h. Then one

switchestocircuit, bywhichawaterloss isavoided and the filterisnot polluted. If

watershall be given again, one onlyhastoswitchthe 3-wayvalvefrom„circuit“to

„filtration“.

The filtermaterialBerkesil KE hastobe prepared alreadyduring operation forthe next

precoating. The precoating materialonlyhastobe stirred then and can immediatelybe

used forfurtherprecoating afterbackwashing of the precoat filter.

Takecarethat during operation of motorpumps, the fuel

tanks arerefilled intime. Careful refilling of the motor

pumpswithfuelisabsolutelyrequired. The sameappliesfor

operation withelectricpumpsforthe current generators.

Important

+

VTroubleshooting

Trouble

Reason Remedy

Electr. pumpormotor

pumpdoesnot primewater

Pumpnot deaerated Deaeratepumpbyfilling up

withwater

Precoat pumpdoesnot primewaterin

spiteofdeaeration Mainball valveofthe 4-

waysuction

deviceisclosed Open corresponding ball

valves

Precoat ball valveofthe 4-way

suction deviceisclosed

Ball valveofthe rawwatercollector

isclosed

Suction deviceisstill hanging on

the suspenderring Hang suction deviceintothe

rawwatertank

Electr. pumpisoperating,

isdeaerated, but doesnot

supplywater

Direction ofrotation ofthe electr.

pumpiswrong Change polesofdirection of

rotation

Electr. pumpsdo not operatethough

protectiveswitchisswitched on and

motorcableisplugged

Fault current protectiveswitchin

the electricdistribution boxhas

released

Switchon FI switchinthe

distribution boxagainafter

having checked it for

defectivecables

One ofthe electr. pumps

doesnot operatethough

the motorcableisplugged

Motorprotectiveswitchhas

released Check pumpforsmooth

running (foreign matter,

damage at the bearing).

Restart motorprotective

switch.

Precoat materialdoesnot adhereto

the filtercandles Circulation ball valveofthe 4-way

suction deviceisclosed Open ball valve

Float ofthe flowratemeter„flutters“

during precoating Precoat filternot deaerated Open deaeration valveat the

precoat filter

Precoat pumpfailed Restart precoat pump

Chlorine dosatordoesnot yield

chlorine Chlorine dosatorisnot deaerated Deaeratechlorine dosator

Needlevalveofthe flowratemeter

isclogged Clean needlevalve

Bag without filling

Refill chlorine lye

Table of contents

Popular Water Filtration System manuals by other brands

Culligan

Culligan HF-360B Installation and operating instructions

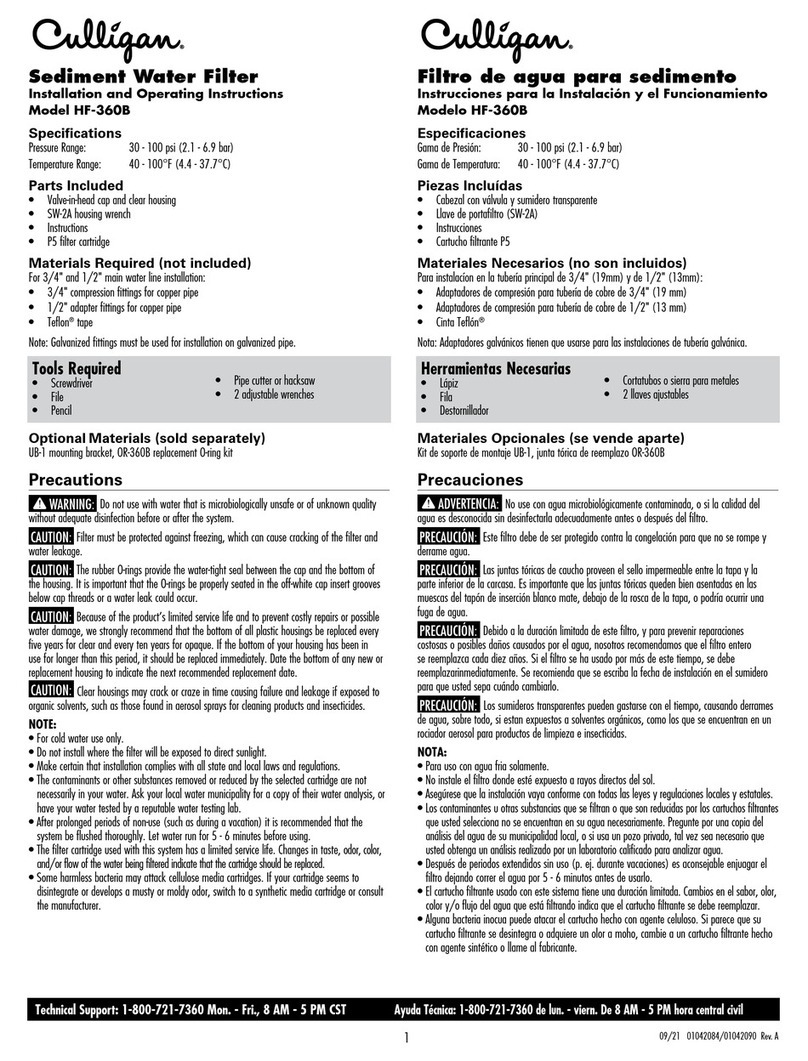

JRC

JRC NSVS1106 manual

Harris

Harris 156593 Installation, operation & parts

Thermo Scientific

Thermo Scientific Smart2Pure Pro Installation and operation

Vizion

Vizion UFL-420 series owner's manual

Waterdrop

Waterdrop WD-G3P800-W instruction manual

Boss Water Systems

Boss Water Systems 021-4P-GM Installation and service guide

Mirus

Mirus Ingenio EZporator MTR 51000 Product user manual

CDA

CDA TF55 manual

Millipore

Millipore ICW-3000 user manual

Crystal Quest

Crystal Quest Thunder Reverse Osmosis installation guide

Kripsol

Kripsol BL Series Handbook for starting