1009719 Rev E2.

INTRODUCTION AND SAFETY

================================================================================================

The safety label shown in this section is placed in important areas on your

product to draw attention to potential safety hazards.

On your product safety labels, the words DANGER, WARNING and CAU-

TION are used with the safety-alert symbol. DANGER identifies the most

serious hazards.

The operator’s manual also explains any potential safety hazards when-

ever necessary in special safety messages that are identified with the word,

CAUTION, and the safety-alert symbol.

CONGRATULATIONS on the purchase of your new Brinly-Hardy De-

thatcher! Your Dethatcher has been designed, engineered and manu-

factured to give you the best possible dependability and performance.

CUSTOMER RESPONSIBILITIES

Please read and retain this manual. The instructions will enable you to as-

semble and maintain your Dethatcher properly.

Please carefully read and observe the SAFETY section of this manual.

Follow a regular schedule in maintaining and caring-for your Brinly-Hardy

Dethatcher.

TABLE OF CONTENTS

SAFETY...................................................................................................... 2

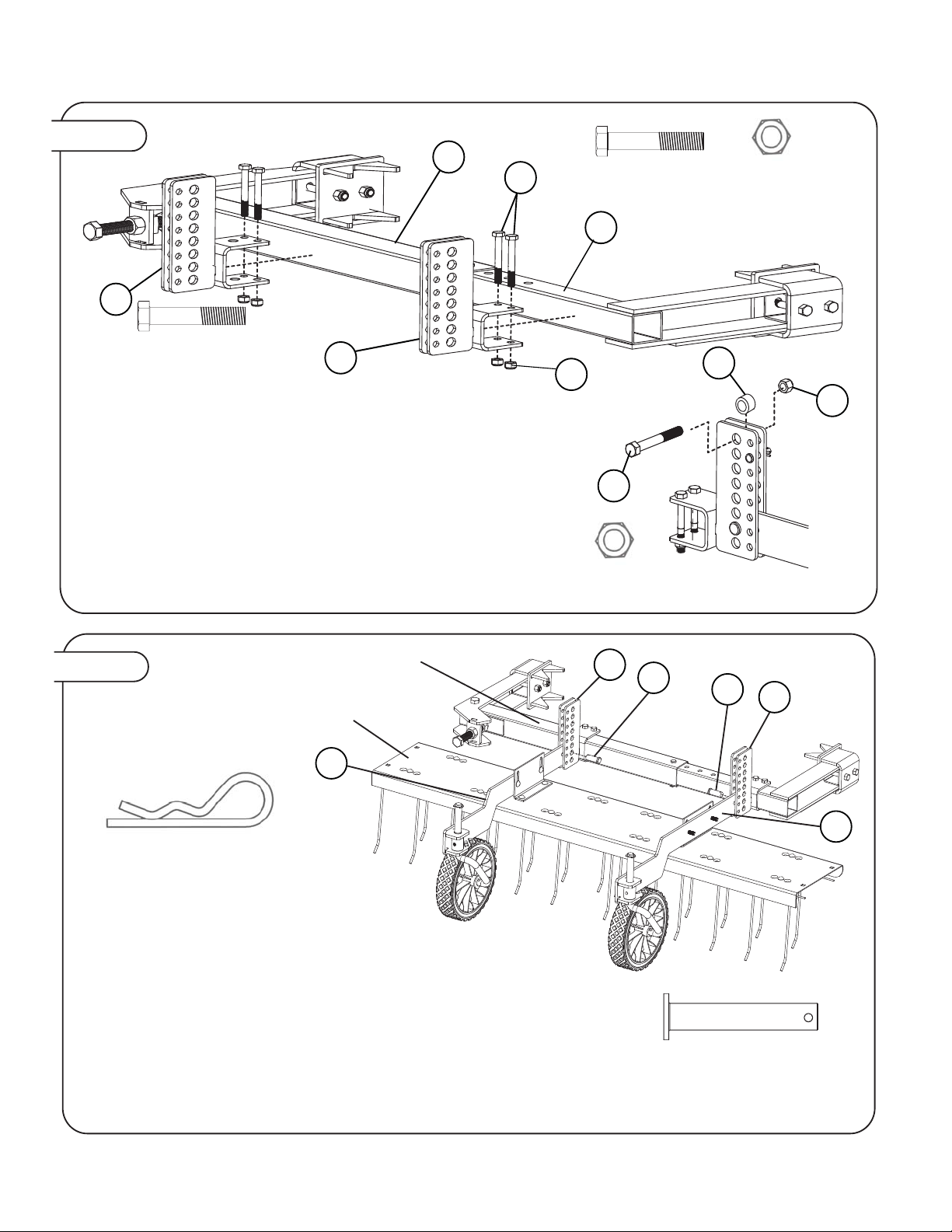

COMPONENT VIEW AND REFERENCE LIST.......................................... 4

ASSEMBLY ............................................................................................. 5-9

OPERATION........................................................................................ 10-11

MAINTENANCE AND STORAGE ............................................................ 12

LIMITED WARRANTY.............................................................................. 12

SAFETY

========================================================

This symbol will help to point out important safety precau-

tions throughout this manual. It means - ATTENTION!

BECOME ALERT! your safety is involved.

GENERAL NOTES (OPERATION)

Caution should be taken when towing and/or using any

attachment. This attachment combined with the weight

distribution, turning radius, and speed of towing vehicle (ie

Zero Turn Mower / ZTR) can result in severe injury or death

to operator, damage to towing vehicle, and/or attachment if

not used properly. Follow all towing safety precautions noted

in the towing vehicle owner’s manual, including the following

precautions:

• Ensure the combined weight of the towing vehicle (tow

vehicle weight + operator weight) is greater than the

maximum towed weight of attachment (empty

attachment weight + weight of load).

• Do not exceed maximum towing capacity of towing

vehicle.

• Do not exceed the maximum drawbar pull rating of the

towing vehicle. Drawbar pull is the horizontal force

required to pull the attachment (including weight of

load).

• Only tow this product in the vehicle’s tow mode/speed

setting or less than 5 mph. Do not exceed 5 mph.

• Towing speed should always be slow enough to

maintain control. Travel slowly and use caution when

traveling over rough terrain. Avoid holes, rocks and

roots.

• Slow down before you turn and do not turn sharply.

• Use wide turning angles to ensure the attachment

follows the path of the towing vehicle.

• Do not use attachment on steep slopes. A heavy

load could cause loss of control or overturn attachment

and towing vehicle. Additional weights may need to

be added to your vehicle; check with

towing vehicle manufacturer for recommendations.

• Reduce towed weight when operating on slopes.

• Keep all movement on slopes slow and gradual. Do

not make sudden changes in speed, directions, or

turning.

• If you start and stop suddenly on hills, you may lose

steering control or the towing vehicle may tip.

Do not start or stop suddenly when going uphill or

downhill. Avoid uphill starts.

• Slow down and use extra care on hillsides. Turf

conditions can affect vehicle stability. Use

extreme caution while operating near drop-offs.

• Do not drive close to creeks, ditches and public

highways.

• Watch out for traffic when crossing near roadways.

• Use care when loading or unloading the vehicle into a

trailer or truck.

• Use extra care when operating in reverse.

• When reversing, carefully back-up straight to avoid

jackknifing. Do not allow towing vehicle wheels to

contact attachment draw bar. Damage could result.

• Stop on level ground, disengage drives, set the parking

brake, and shut off engine before leaving the operator’s

position for any reason including emptying the

attachment.

• Use this attachment for intended purpose only.

• This attachment is intended for use in lawn care and

home applications. Do not tow behind a vehicle on a

highway or in any high speed applications.

Do not tow at speeds higher than the maximum

recommended towing speed.