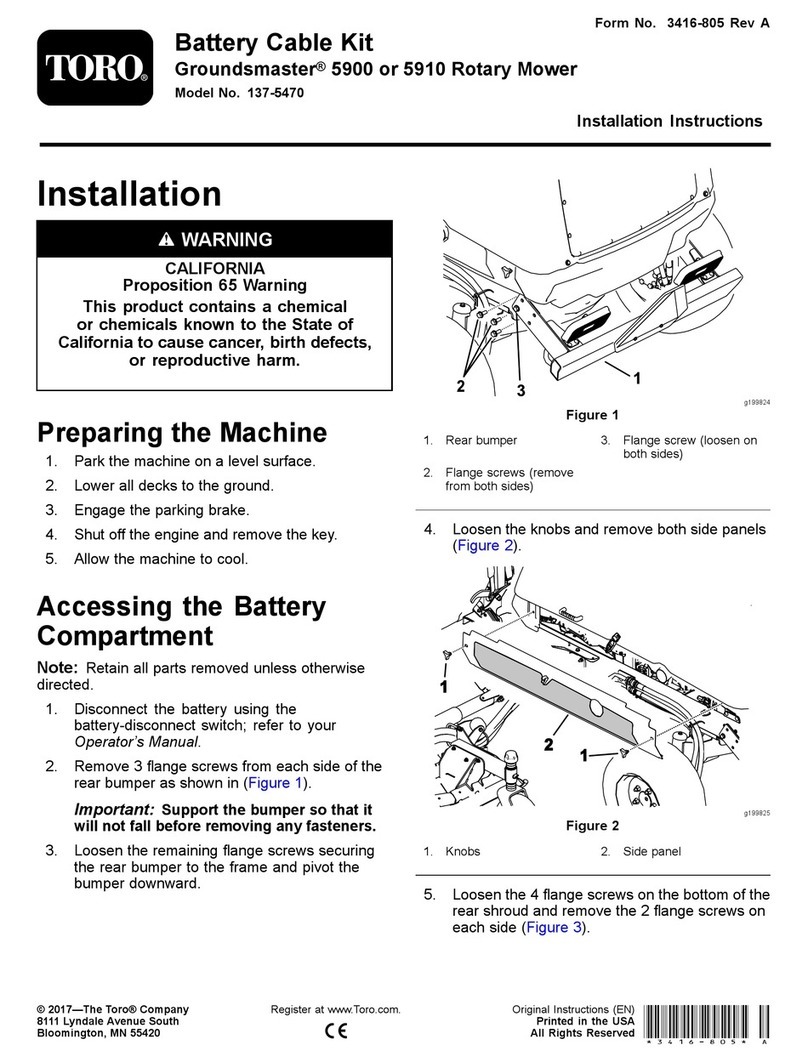

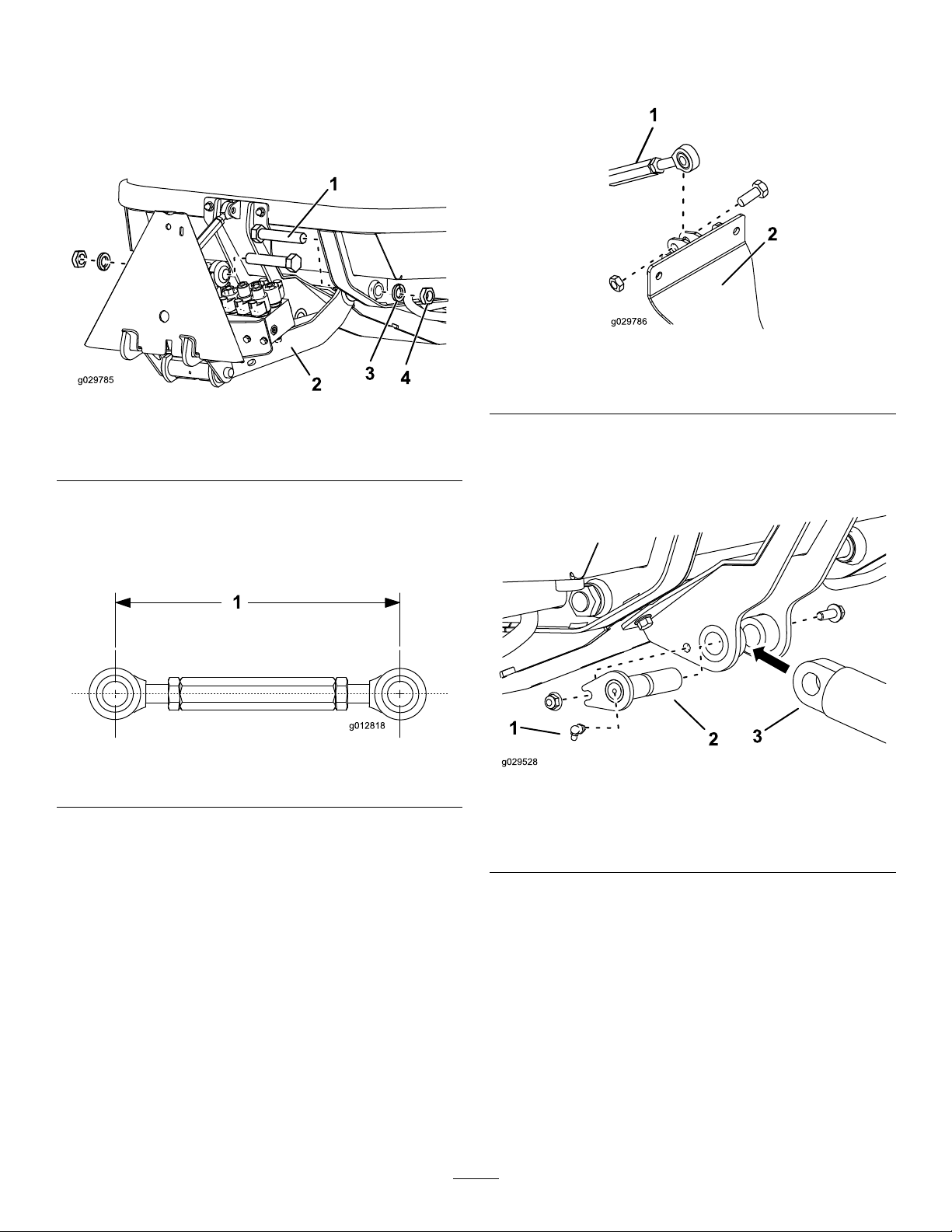

3.Mountthelift-armassemblytotherearframe

members,with2bolts(7/8x4-1/2inch),2jamnuts

(7/8inch),andasmanyspindlewashersasnecessary

toevenlyshimbetweentherightandleftsidesofthe

liftarmandrearframemembers.

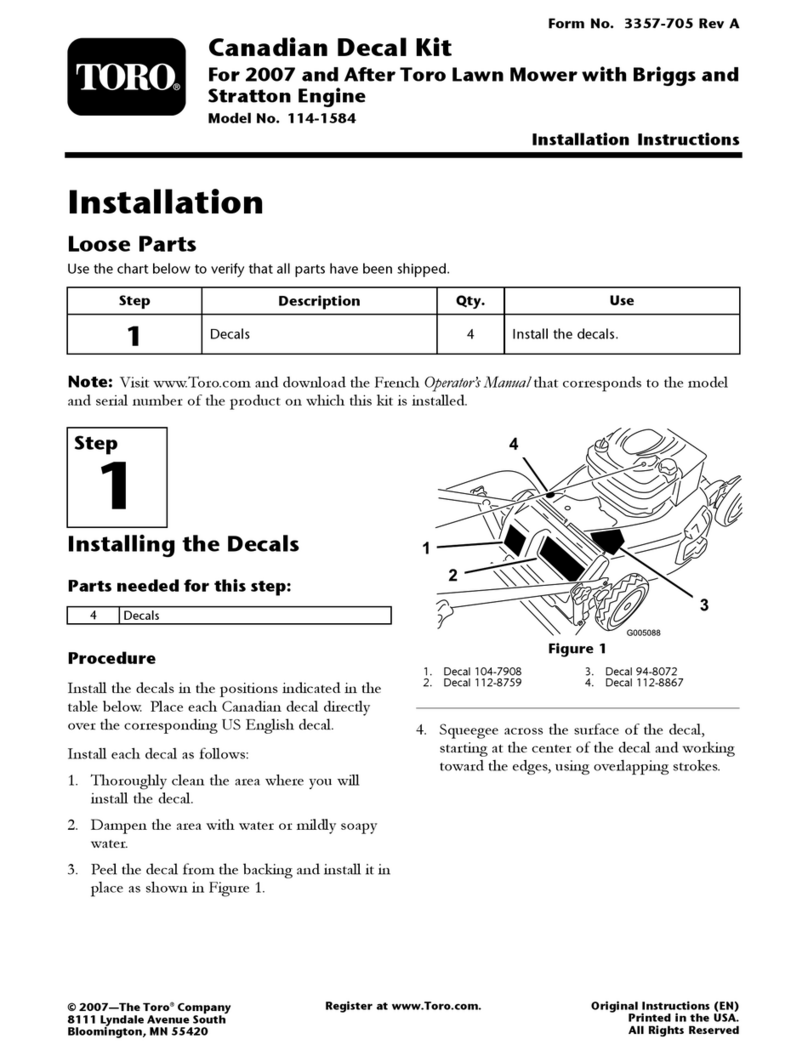

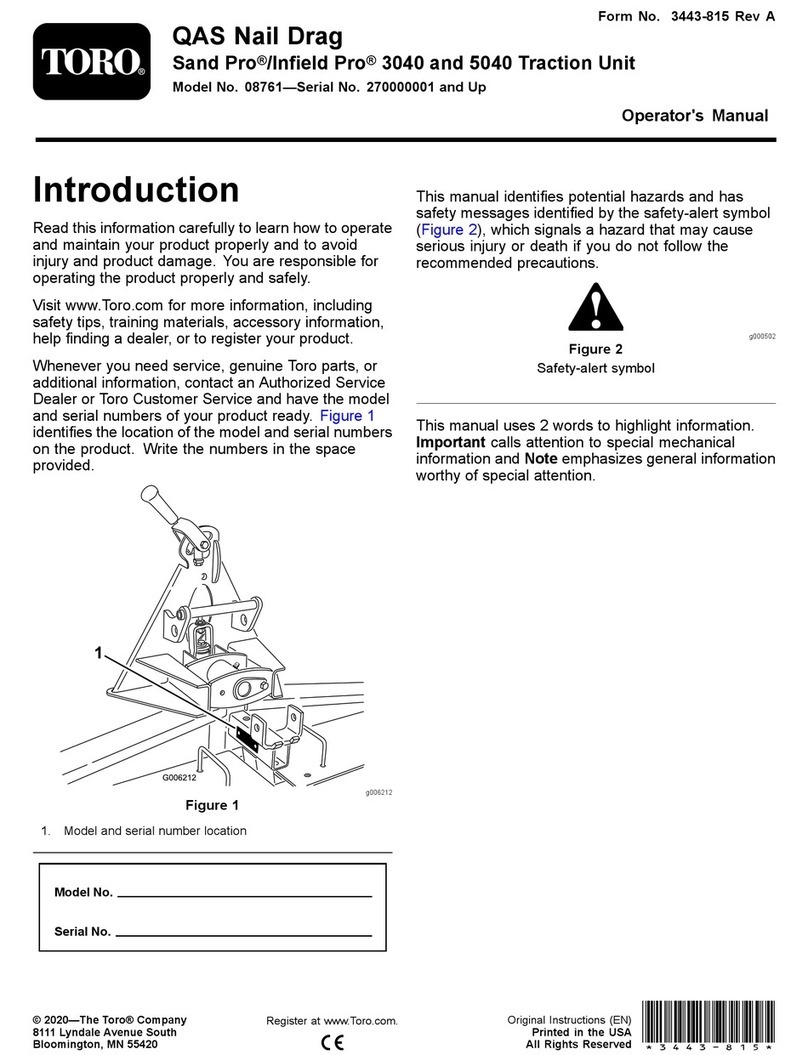

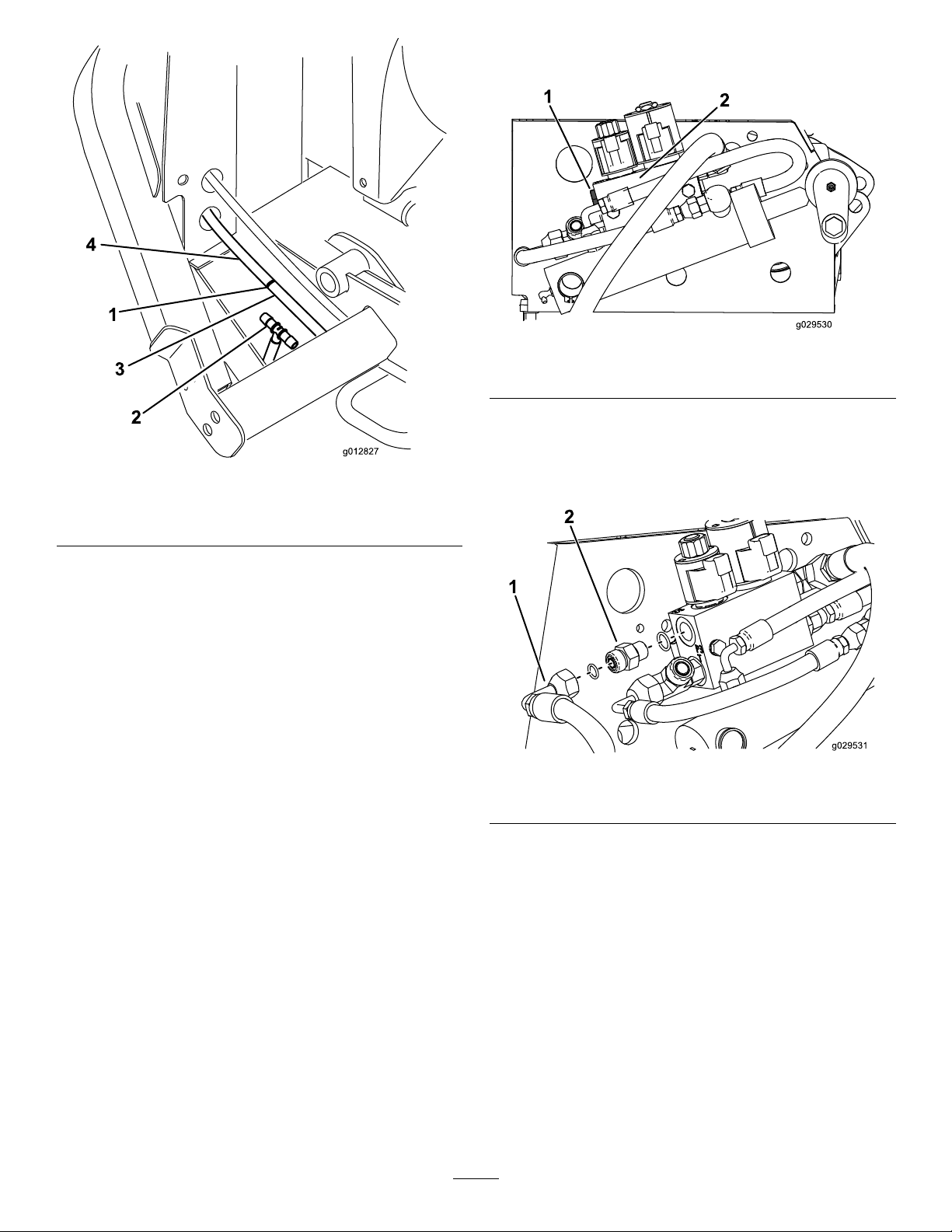

Note:PositionthecomponentsasshowninFigure3.

Figure3

1.Bolt(7/8x4-1/2inch)3.Spindlewasher

2.Lift-armassembly4.Jamnut

4.Torquetheboltsandlocknuts518to648N-m(382

to478ft-lb).

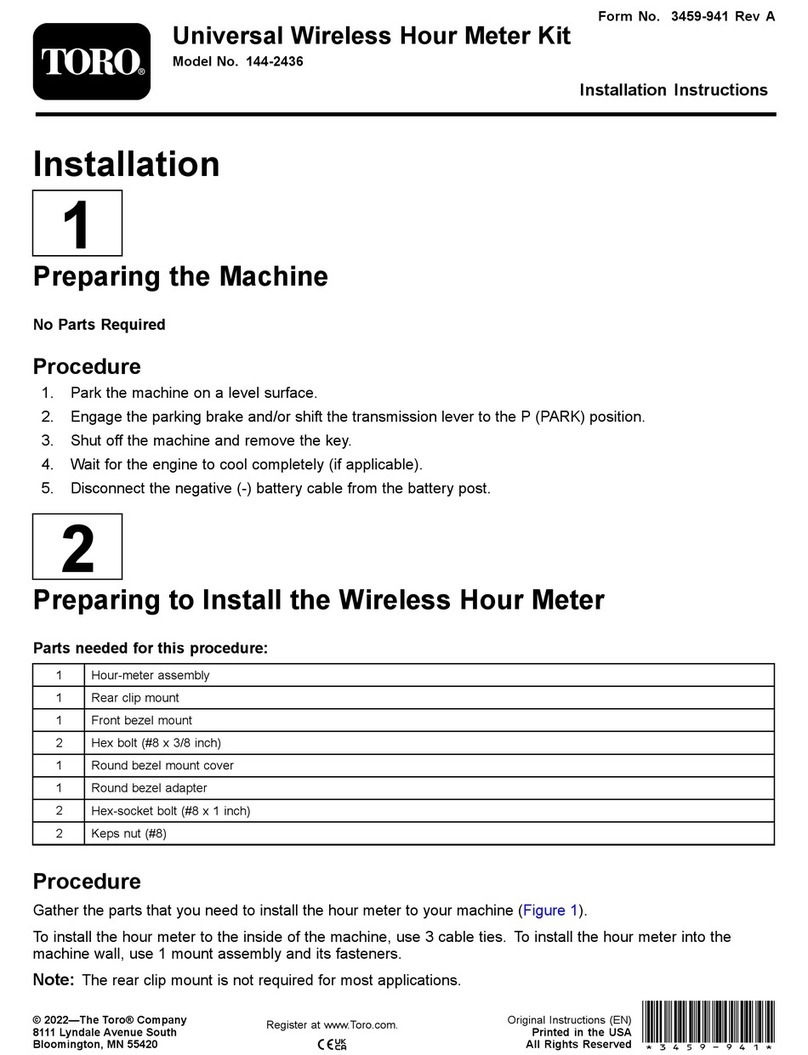

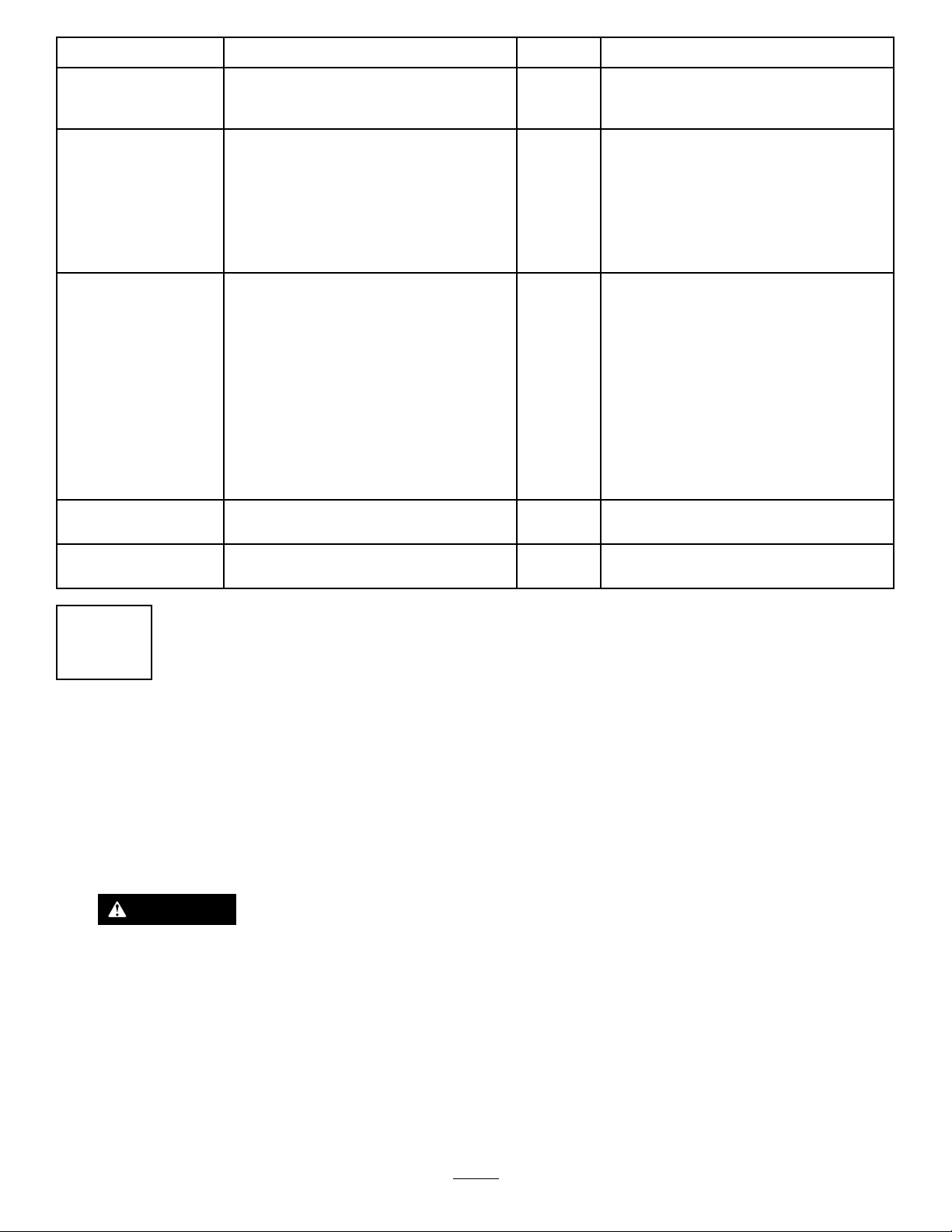

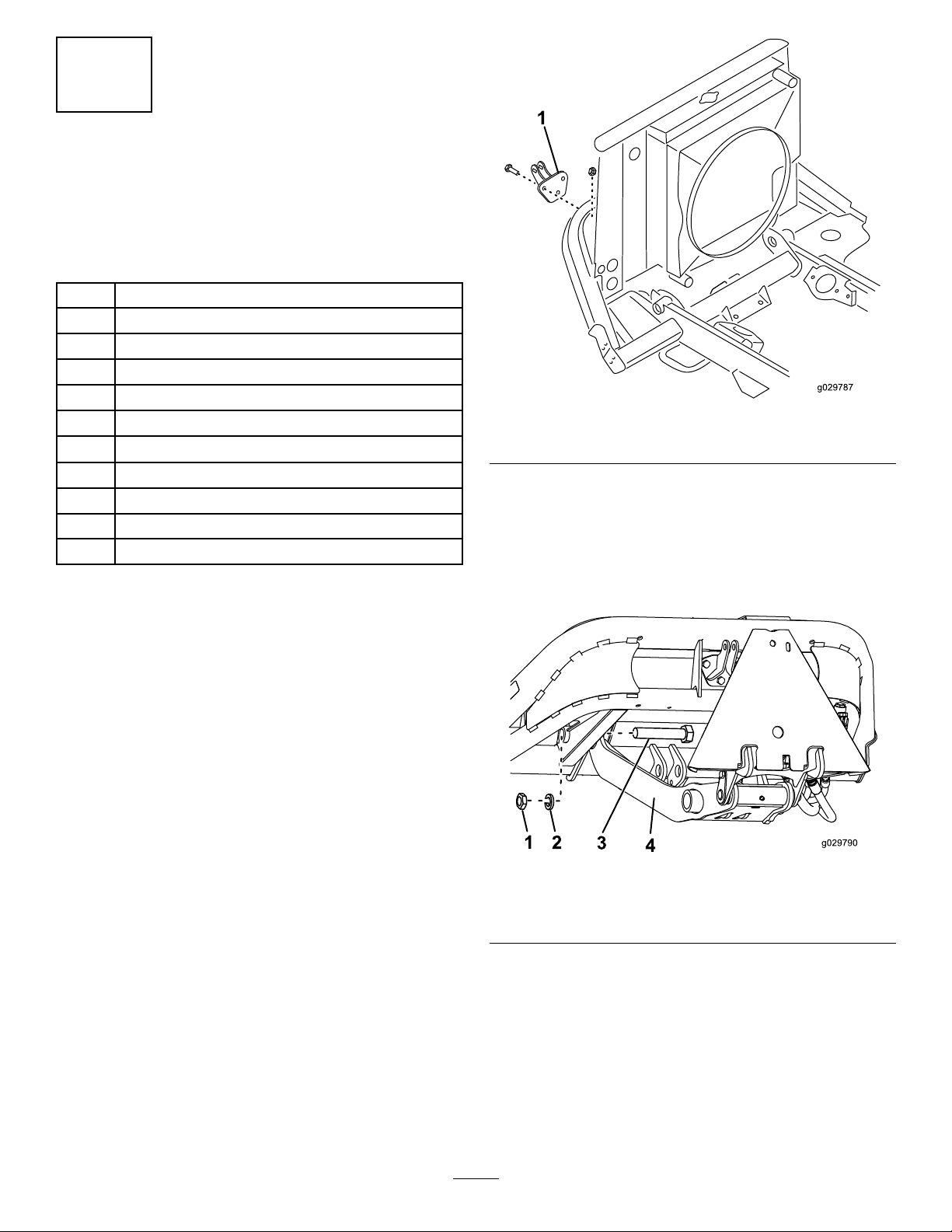

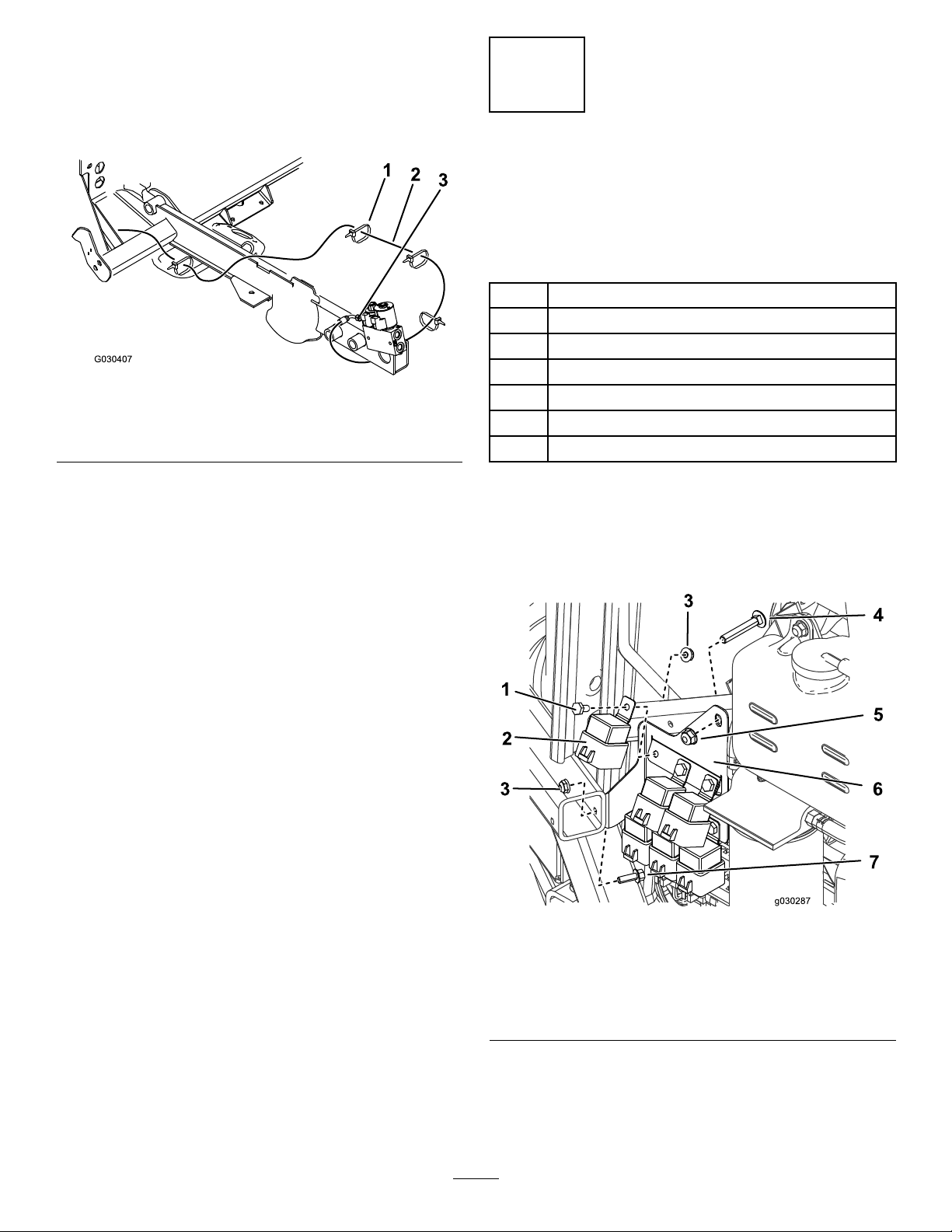

5.Adjustthelengthofthethreadedlinkto19cm(7-1/2

inches)andtightenthejamnuts(Figure4).

Figure4

1.Lengthofthreadedlink—19cm(7-1/2inches)

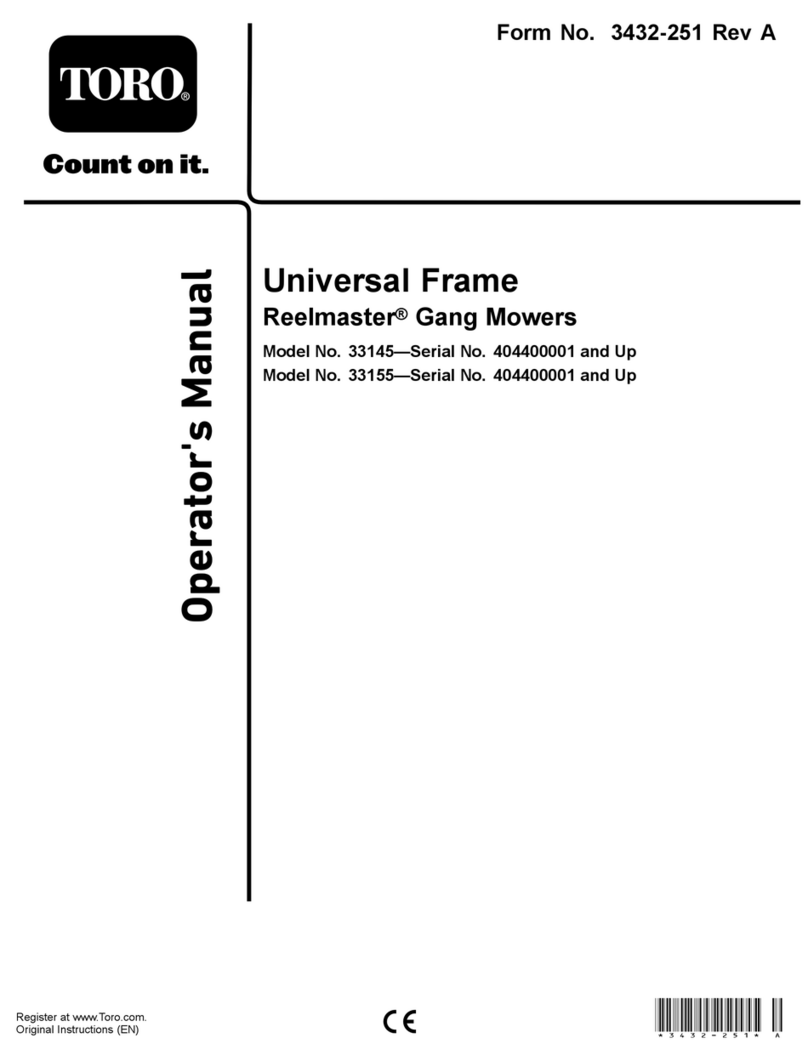

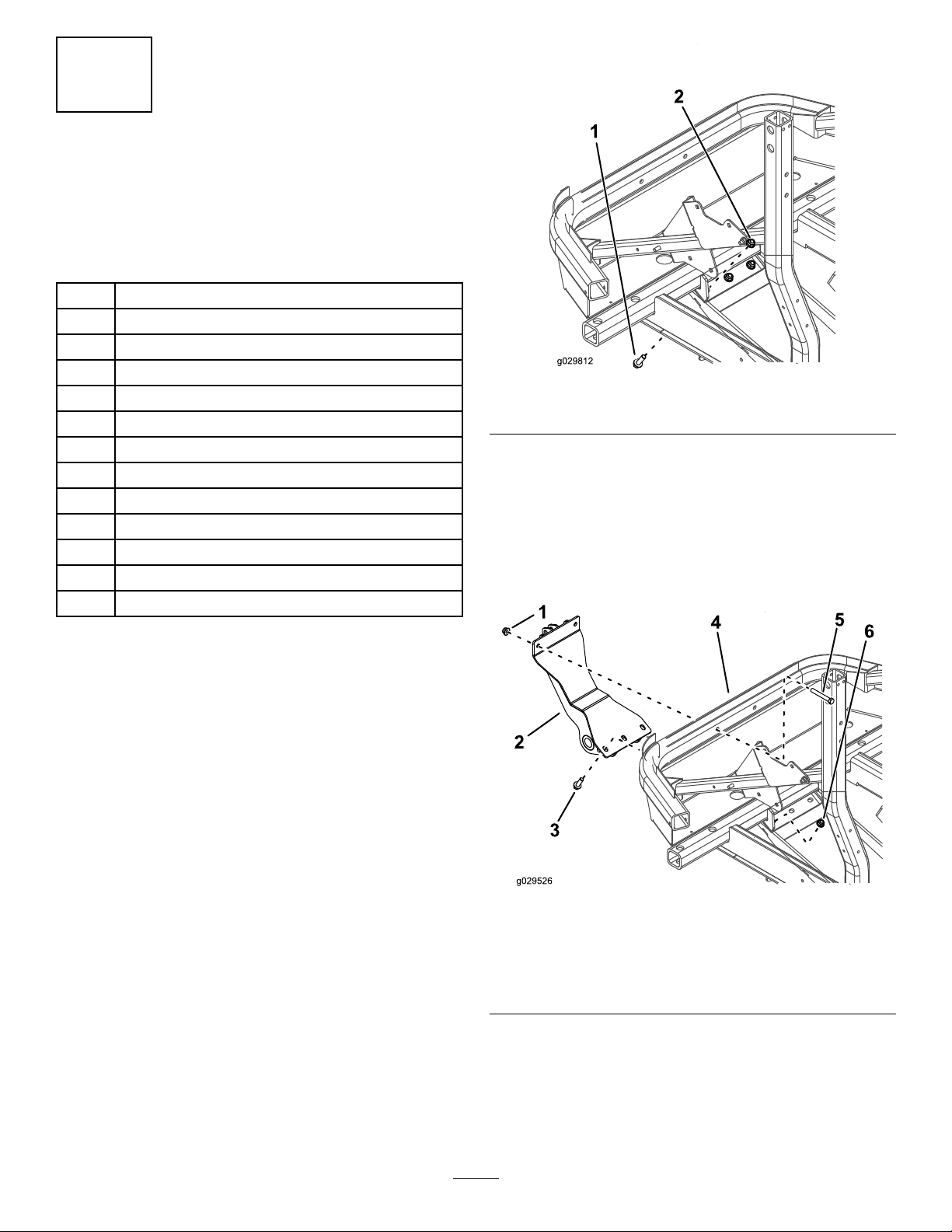

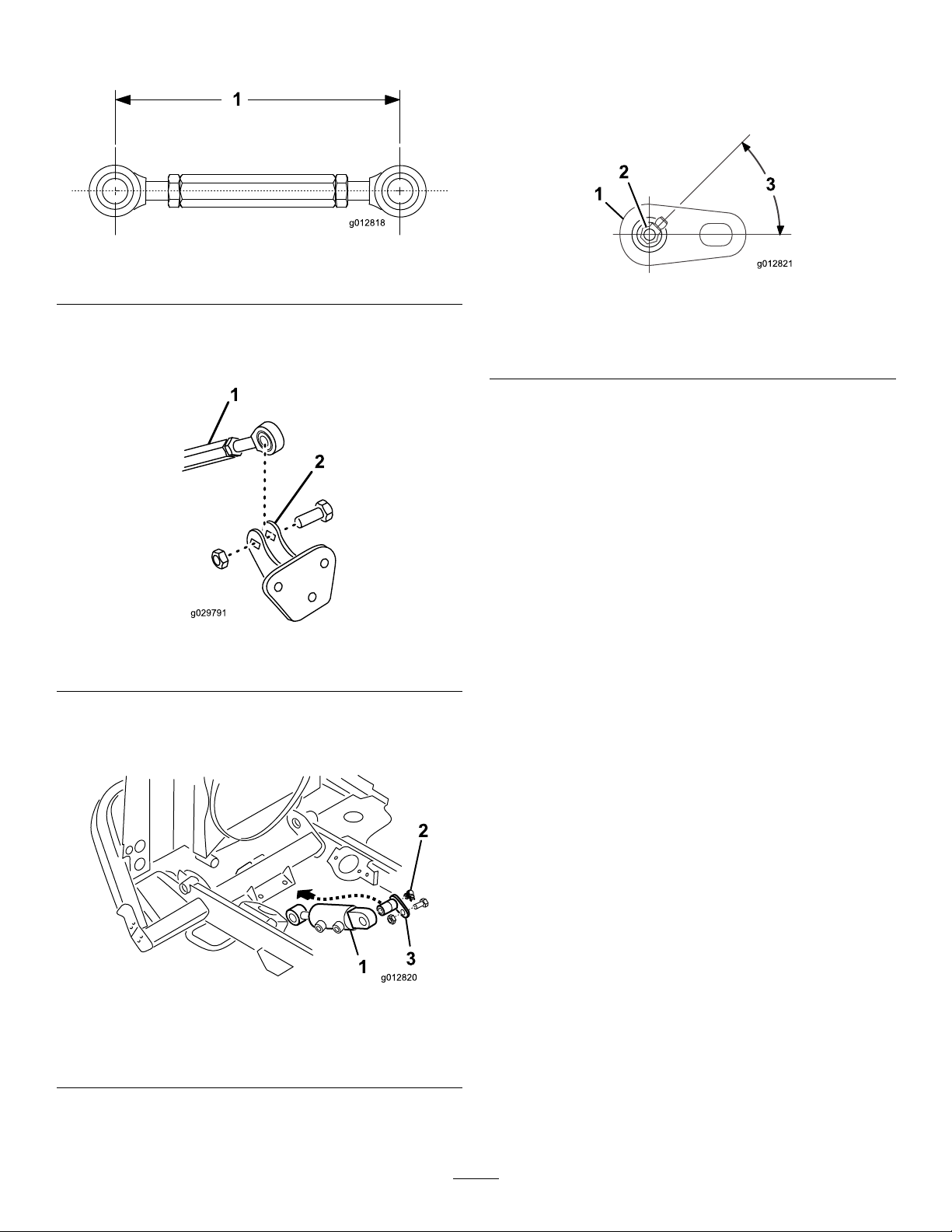

6.Securethethreadedlinkrodendtothecylinder-support

assemblywithabolt(1/2x1-1/2inch)andlocknut

(1/2inch)asshowninFigure5.

Figure5

1.Liftadapter2.Cylinder-support

assembly

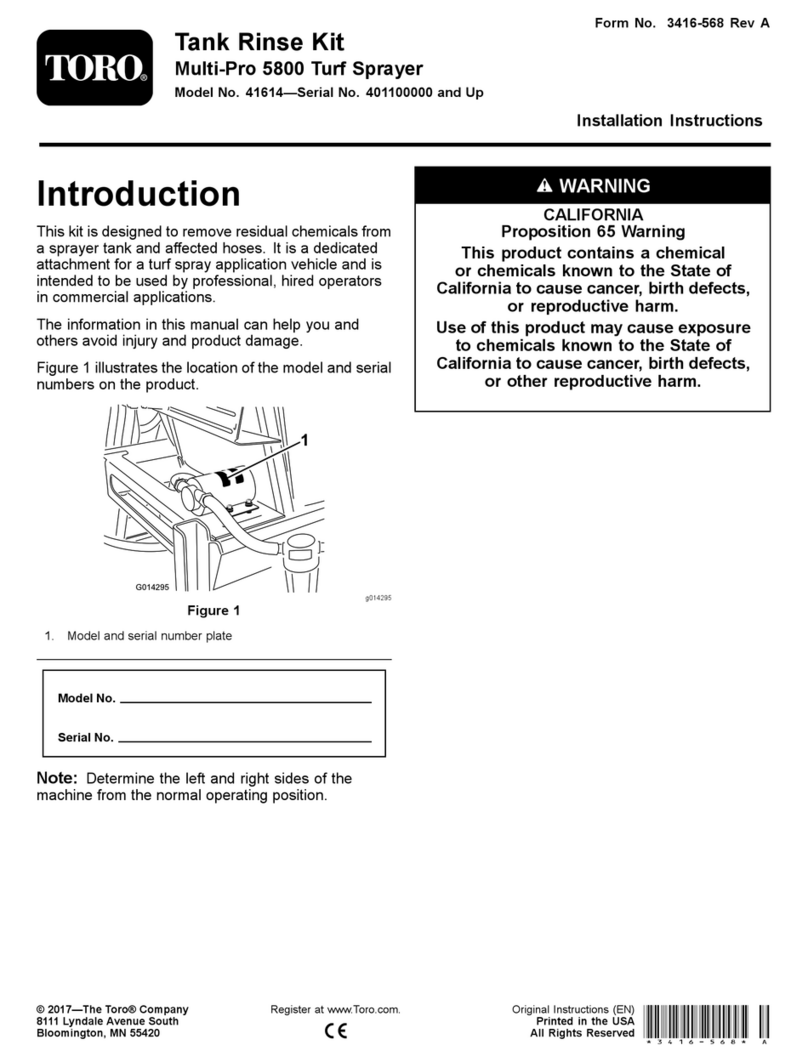

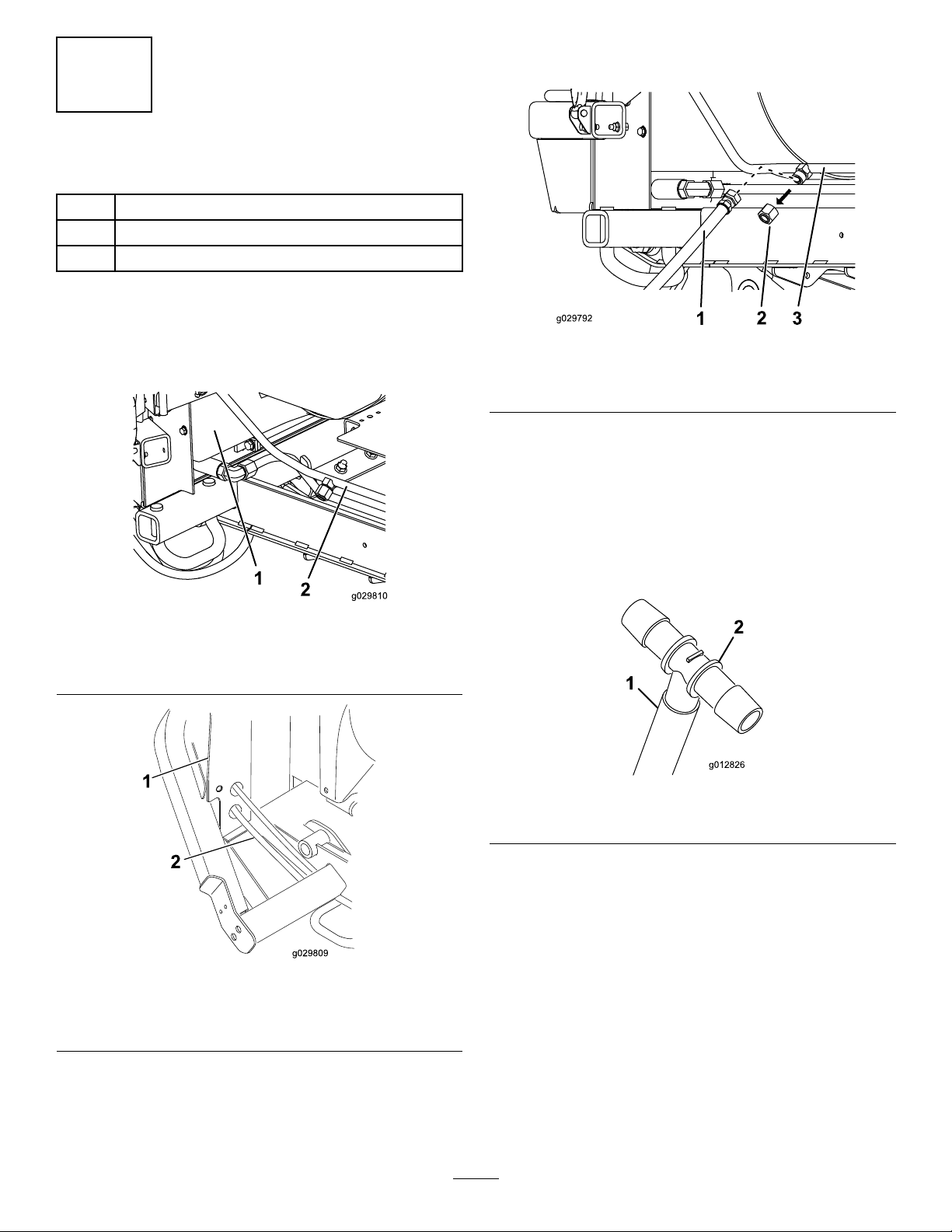

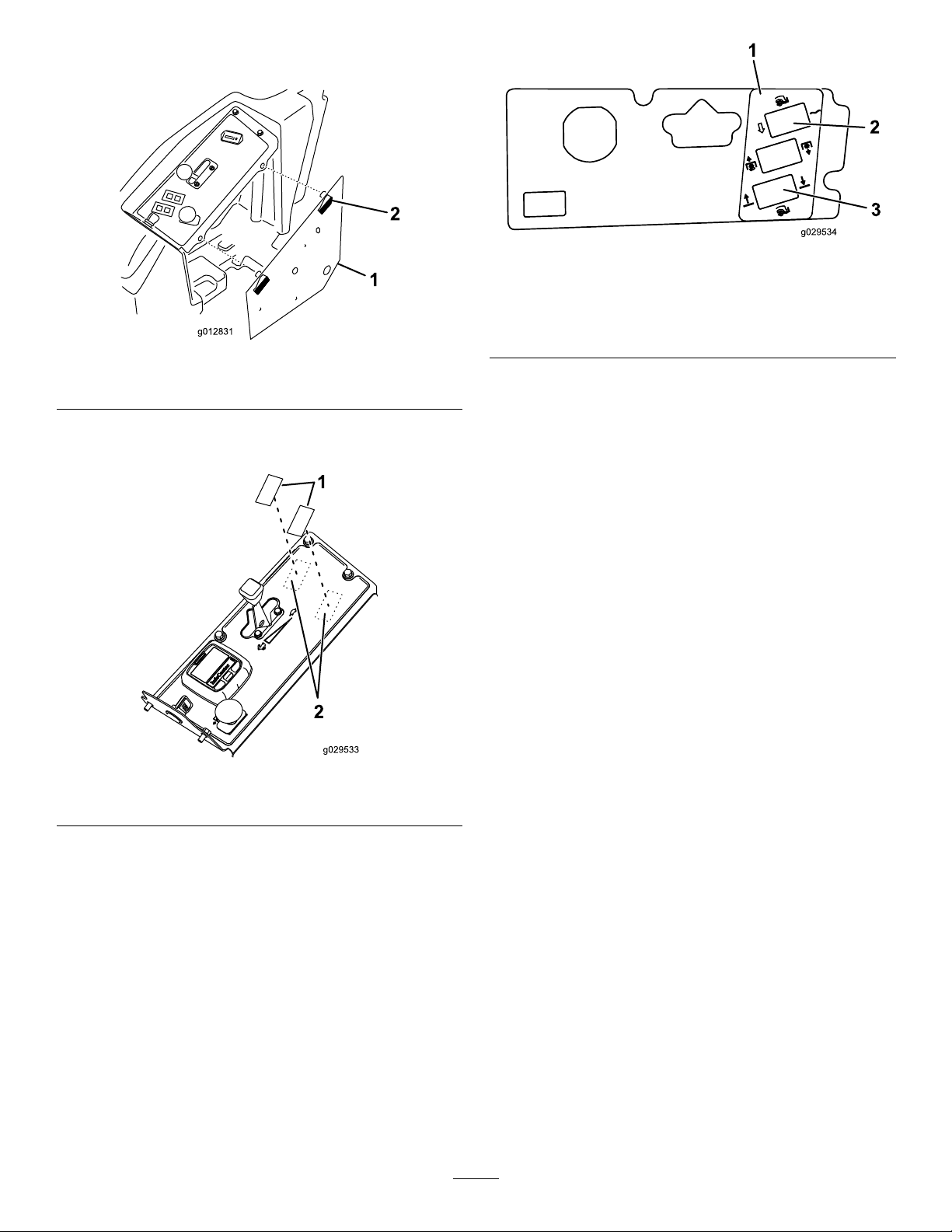

7.Mountthelooseendofthehydrauliccylindertothe

cylinder-supportassemblywiththecylinder-mount

pivotpin,bolt(3/8x1inch),andnut(3/8inch)as

showninFigure6.

Figure6

1.Greasetting3.Hydrauliccylinder

(stationeryend)

2.Pivotpin

8.Threadagreasettingintotheendofthepivotpinas

showninFigure6.

4