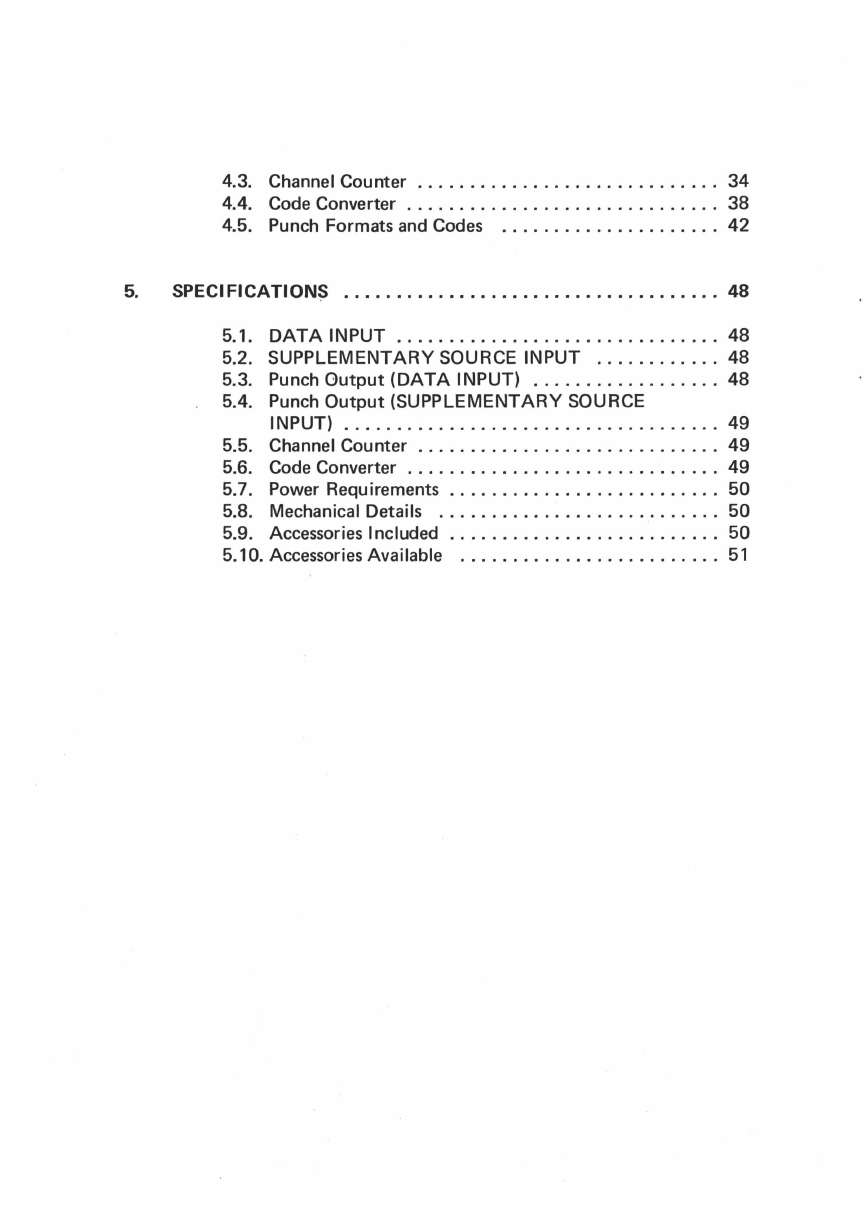

CONTENTS

1.

INTRODUCTION

......................................

5

2.

CONTROLS

..........................................

7

2.1.

Front

Panel

of

Tape Punch

Type

6301

.............

7

2.2. Rear

Panel

of

Tape Punch

Type

6301

..............

8

3.

OPERATION

........................................

10

3.1. Preliminary Adjustments

.............

.

........

10

3.2. Loading Paper Tape

..........................

10

3.3. Operation

as

a Recording Medium

...............

12

3.4. Operation

with

8 & K Real

Time

Third

Octave

Analyzer Type 3347

..........................

13

3.5. Operation

with

8 & K Digital Encoder,

Type

4421

.................................

15

3.6. Operation

with

8 & K Manual Data

Unit,

Type

5599 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.

7. Operation

with

8 & K Digital Event Recorder,

Type

7502

.................................

19

3.8. Operation

with

8 & K Computer,

Type

7504

.......

21

4.

DESCRIPTION

.......................................

23

4.

1.

General . . . . . . . . . . . . ... . . . . . . . . . . . . . . . . . . . . . .

23

Parallel

to

Series Converter and

Control

Logic

......

24

Channel Counter

.............................

24

Code Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

Data and Control Line

Switch

..................

25

Punch Circuits

..............................

25

4.2. Rear Connectors and Control Signals

.............

26

DATA

INPUT

socket

.........................

26

SUPPLEMENTARY

SOURCE

INPUT

socket

.......

31