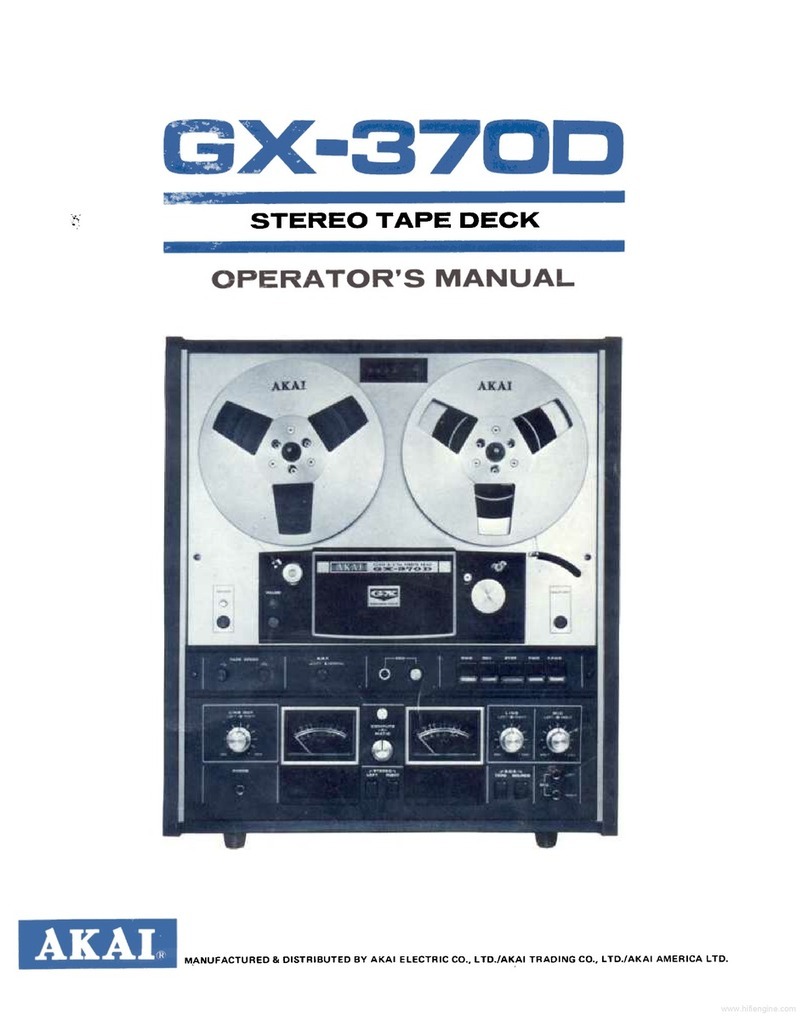

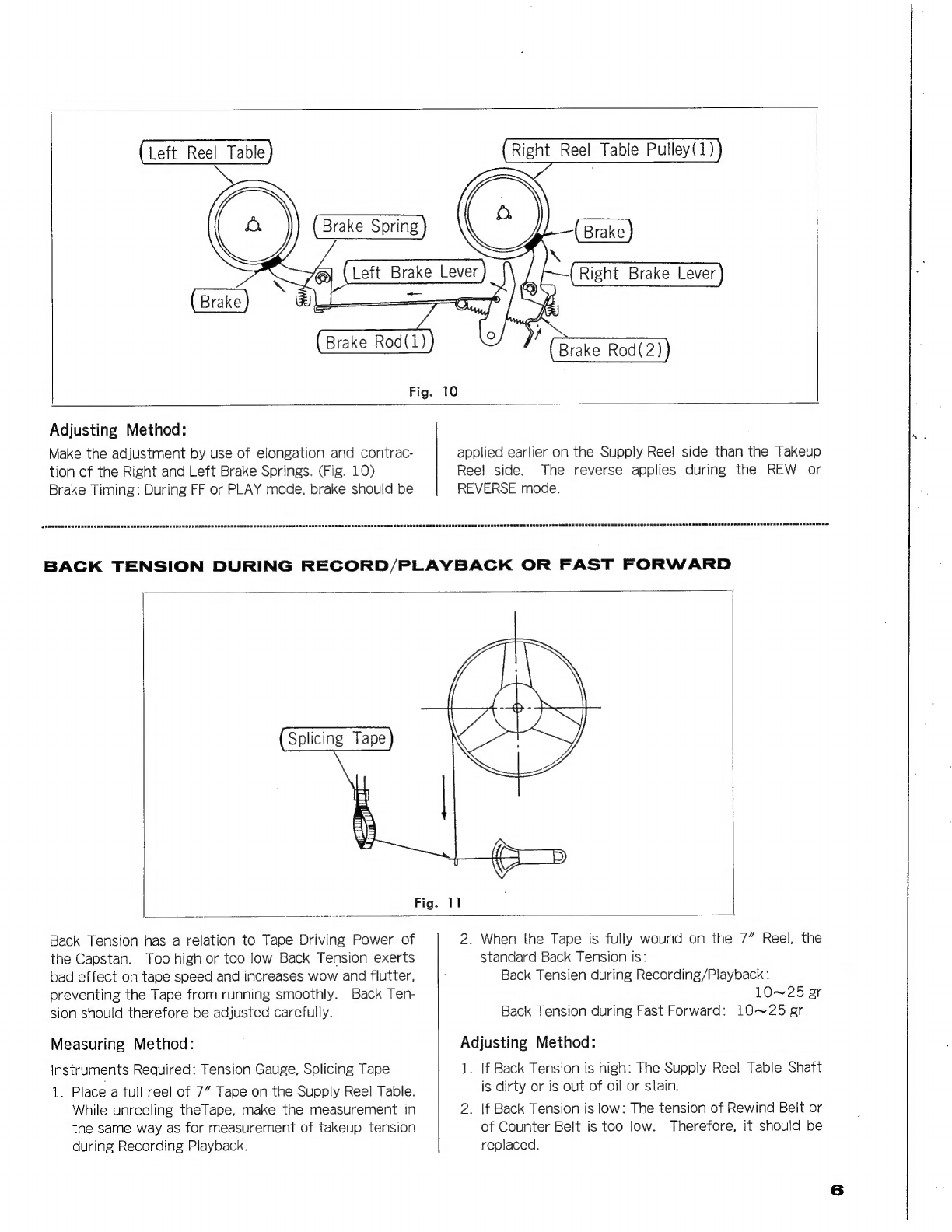

Left

Reel

Table

Brake

Rod(1)

Fig.

10

Right

Reel

Table

Pulley(1)

Adjusting

Method:

Make

the

adjustment

by

use

of

elongation

and

contrac-

tion

of

the

Right

and

Left

Brake

Springs.

(Fig.

10)

Brake

Timing:

During

FF

or

PLAY

mode,

brake

should

be

SA

een

ee

a

nee

deen

nme

RGRER

AREA

SORA

RERR

Re

nRHER

AHR

ARN

ON

RON

SRETORNOR

ESE

REN

ARR

ead

eon

Ree

ERRE

NORE

ROSRHOEReEsREAeedEenensonnen:

applied

earlier

on

the

Supply

Ree!

side

than

the

Takeup

Ree!

side.

The

reverse

applies

during

the

REW

or

REVERSE

mode.

non

RonaDa

SE

seRnnenuenennsessenneensasuaunnnESennnennaaesansnaennnnnenenn

eke

nODRGRRGESRRARHAHREOEESEMERMAnannnenneanons

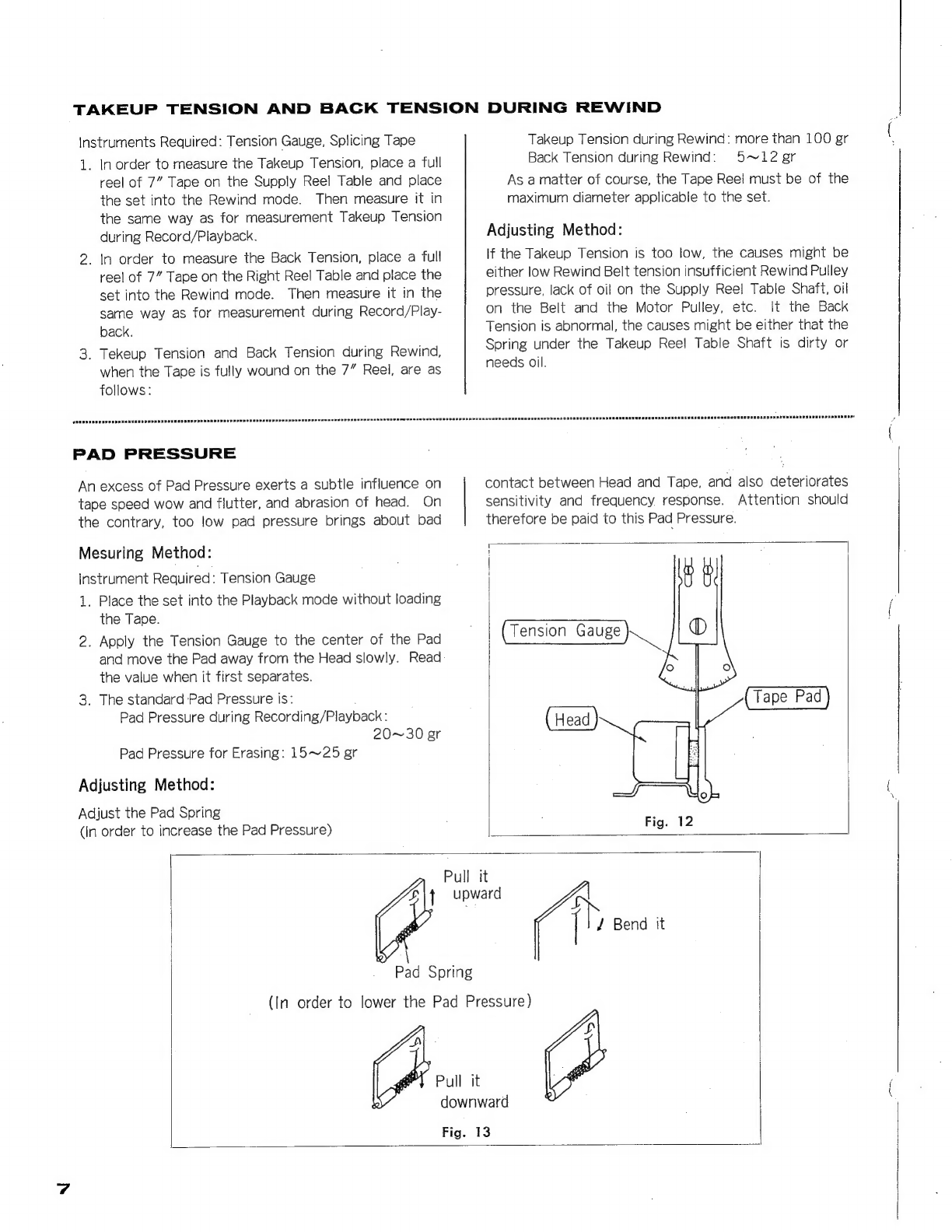

BACK

TENSION

DURING

RECORD/PLAYBACK

OR

FAST

FORWARD

Back

Tension

has

a

relation

to

Tape

Driving

Power

of

the

Capstan.

Too

high

or

too

low

Back

Tension

exerts

bad

effect

on

tape

speed

and

increases

wow

and

flutter,

preventing

the

Tape

from

running

smoothly.

Back

Ten-

sion

should

therefore

be

adjusted

carefully.

Measuring

Method:

Instruments

Required:

Tension

Gauge,

Splicing

Tape

1.

Place

a

full

reel

of

7”

Tape

on

the

Supply

Reel

Table.

While

unreeling

theTape,

make

the

measurement

in

the

same

way

as

for

measurement

of

takeup

tension

during

Recording

Playback.

2.

When

the

Tape

is

fully

wound

on

the

7”

Reel,

the

standard

Back

Tension

is:

Back

Tensien

during

Recording/Playback

:

10~25

ger

Back

Tension

during

Fast

Forward:

10~25

gr

Adjusting

Method:

1.

If

Back

Tension

is

high:

The

Supply

Reel

Table

Shaft

is

dirty

or

is

out

of

oil

or

stain.

2.

|f

Back

Tension

is

low:

The

tension

of

Rewind

Belt

or

of

Counter

Belt

is

too

low.

Therefore,

it

should

be

replaced.