PAGE 10 BRUNSWICK INSTALLATION MANUAL

BLACK WOLF PRO

ATTACHING BED CLOTH TO

FRAMED SLATE (CONTINUED)

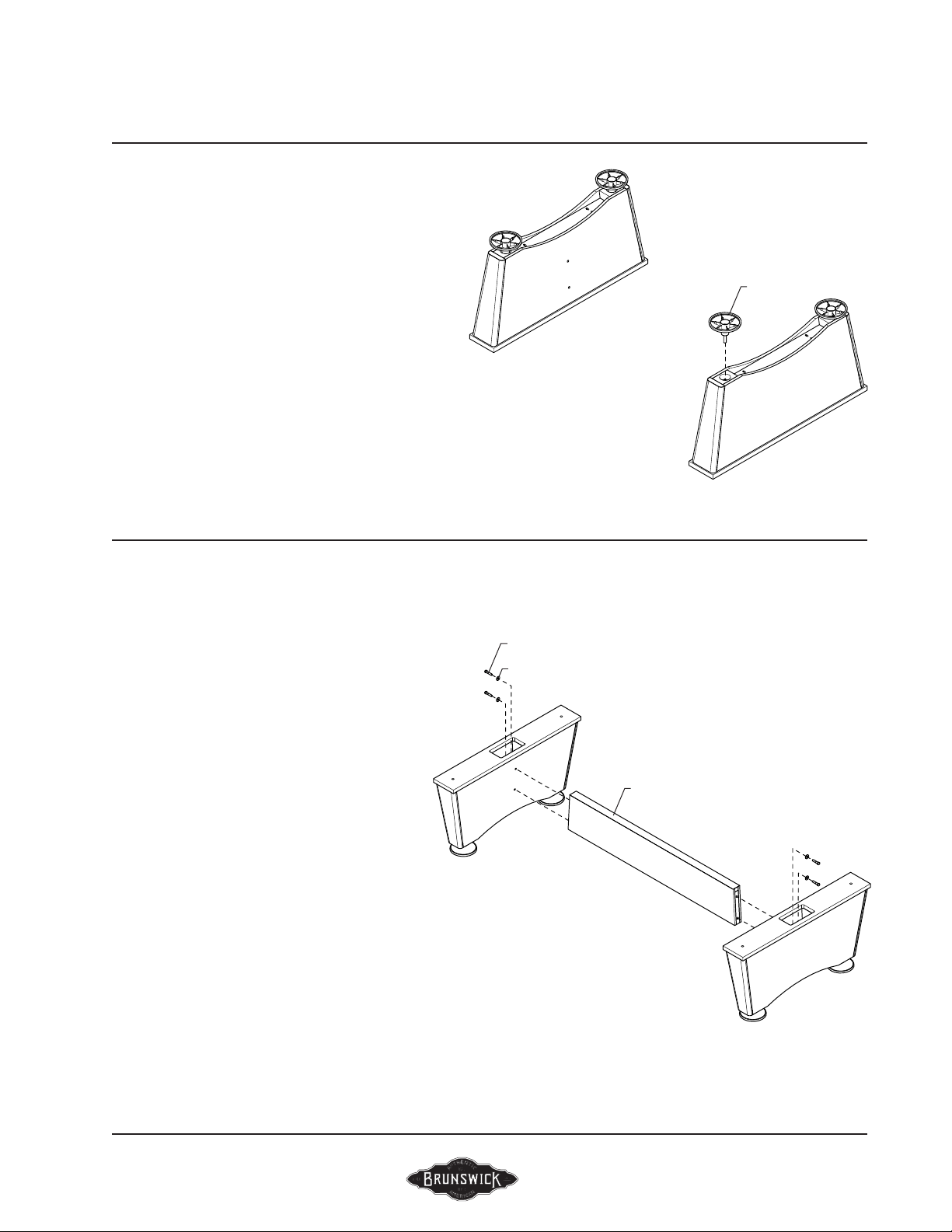

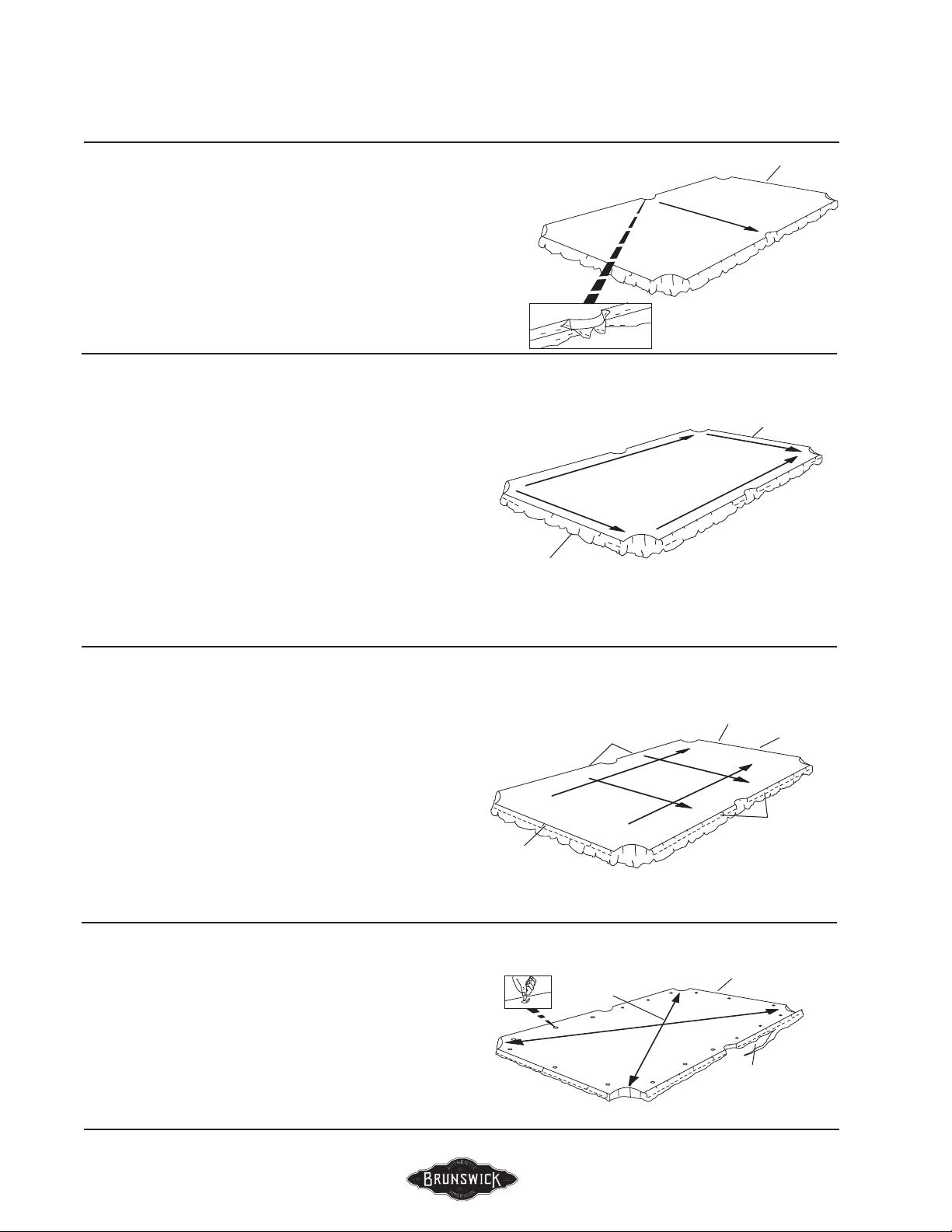

FIGURE FOUR

Step #11: At location #9, cut a short slit in the cloth at

the edge centered on the side pocket opening. Grasp the

cloth rmly above this slit, pull the cloth into the side

pocket opening and tack or staple to the wood frame.

Complete fastening of the cloth to the side pocket

opening, making sure the cloth is tacked or stapled to

the wood frame.

Step #12: Stretching the cloth tightly across the table

from location #9, repeat Step 11 at location #10.

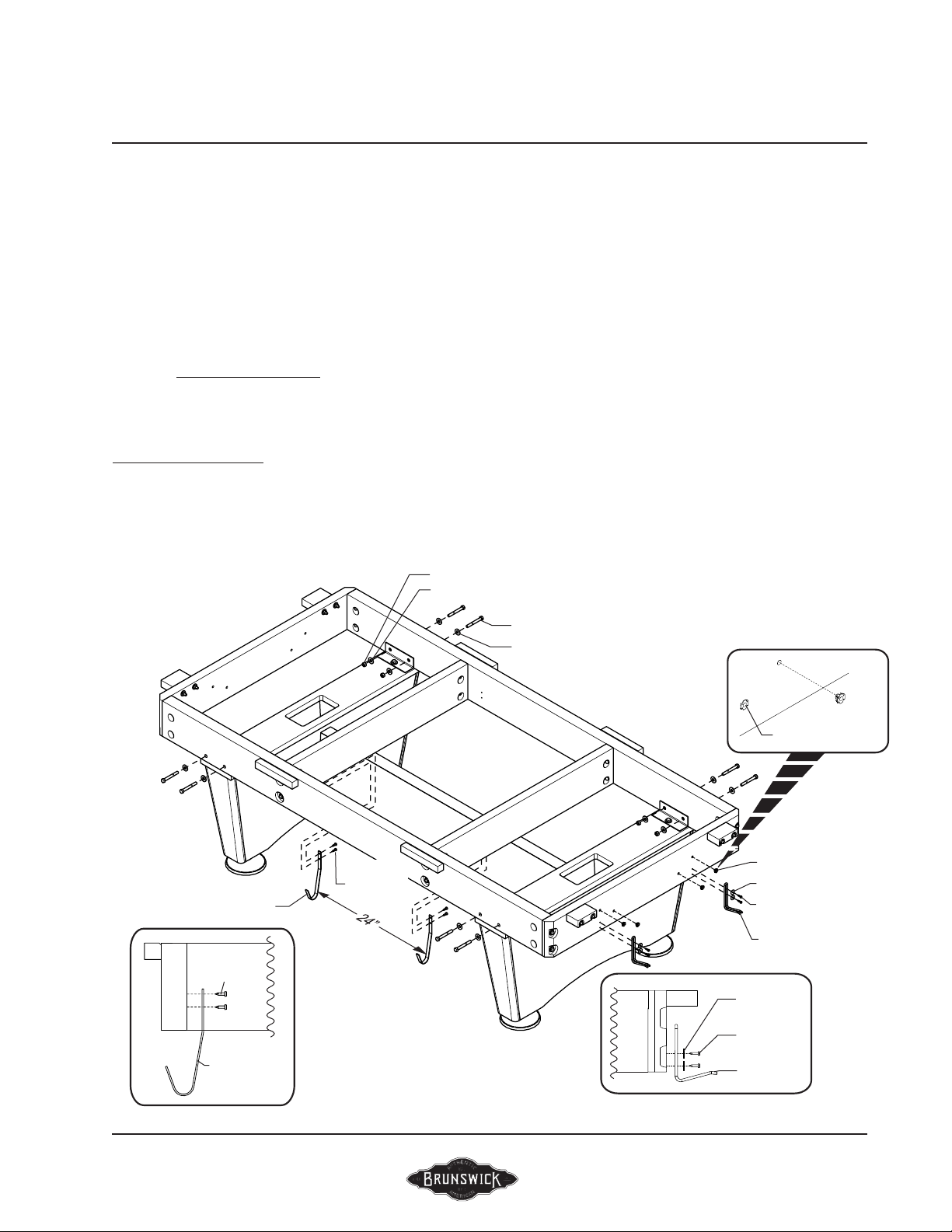

FIGURE FIVE

Step #13: At the head end of the table, tack or staple the

cloth at location #11, maintaining uniform overhang.

Step #14: Pull the cloth from location #11 toward

location #12 and tack or staple securely along the wood

frame, keeping the cloth even along the head end.

Step #15: Stretch the cloth rmly from location #11 to

the foot end of the table and tack or staple at location

#13.

Step #16: Stretch the cloth tightly from locations #12

and #13 toward location #14 and tack or staple securely

along the wood slate frame.

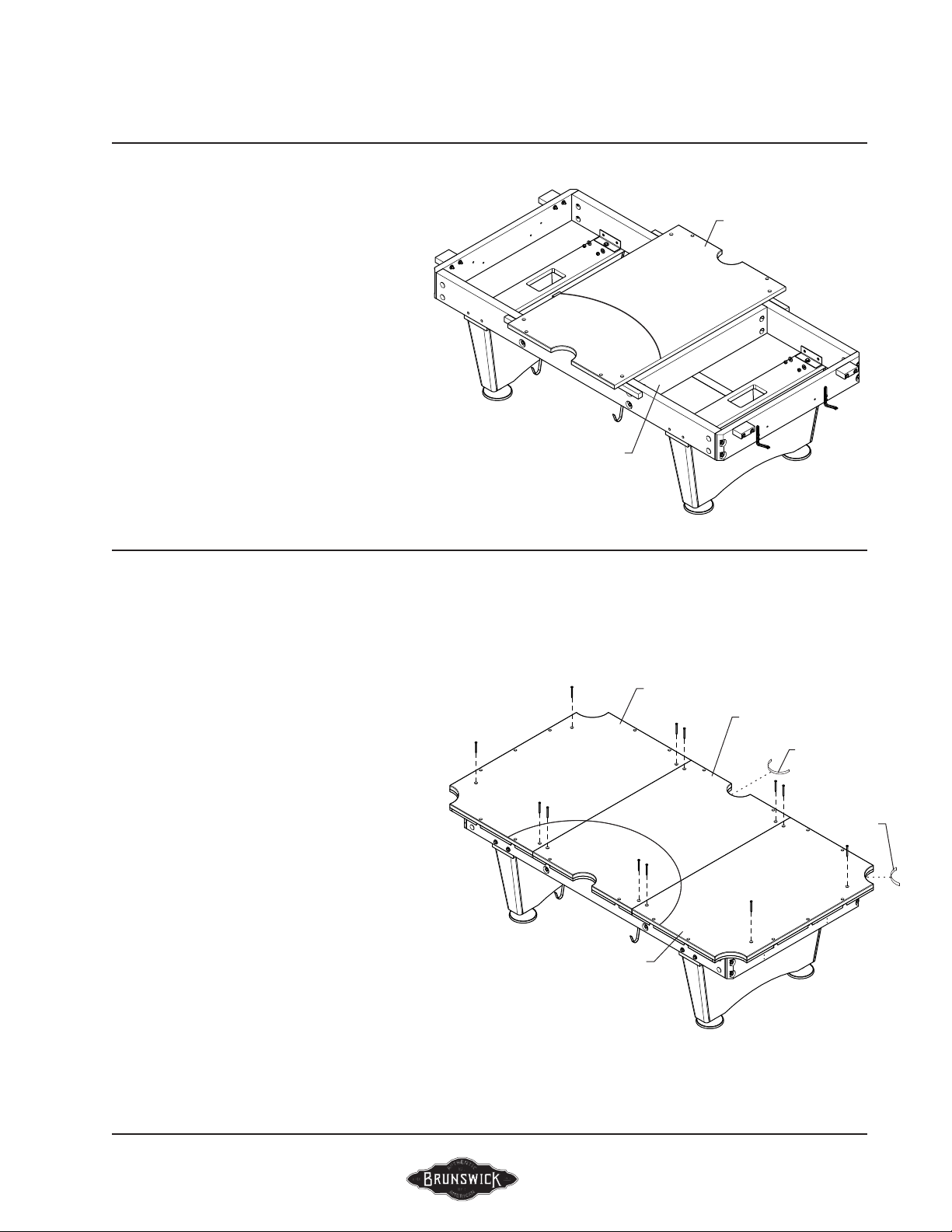

FIGURE SIX

Step #17: Tack or staple all of the left side on 2" centers

keeping the cloth even along the wood frame.

Step #18: Tack or staple the balance of the head end on

2" centers also keeping the cloth even along the wood

frame.

Step #19: Stretch the cloth tightly toward the foot end of

the table, tacking or stapling on 2" centers along the

wood frame at the foot end.

Step #20: Stretch the cloth tightly across the table to the

right side, tacking or stapling on 2" centers all the way

along the wood frame at the right side.

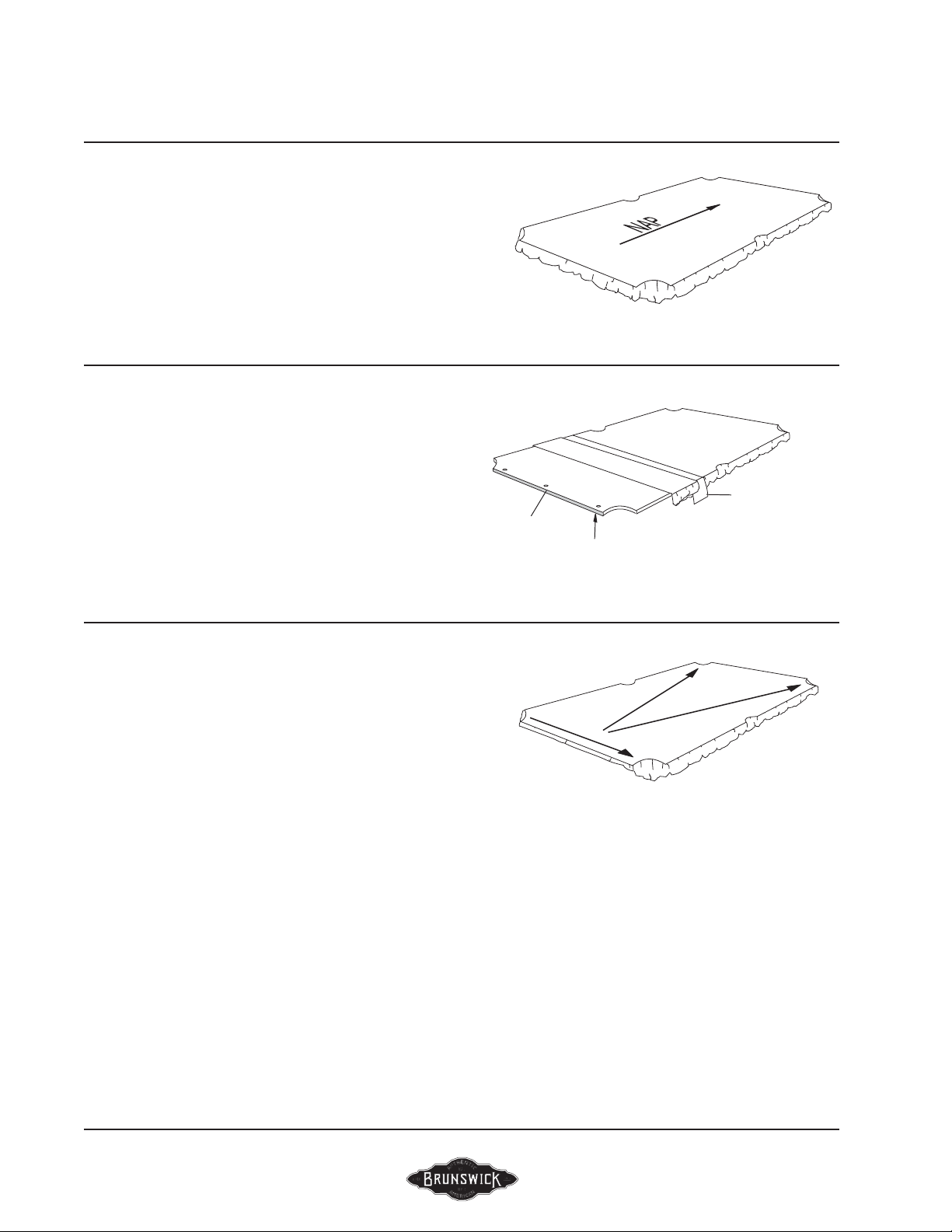

FIGURE SEVEN

Step #21: Stretch the cloth into the corner pocket

openings and tack or staple to the wood slate frame.

Step #22: Trim off excess cloth around the perimeter of

the slate. Locate the eighteen (18) rail attach holes and

cut clearance holes in the cloth with a sharp knife.

NOTE:

Occasionally cloth will stretch, leaving wrinkles

at the pockets. To retighten, remove apron, one end rail

and one side rail. Pull cloth taut, and retack or restaple

along the open end and side to restore original tightness.

FIGURE FOUR

FIGURE FIVE

FIGURE SIX

FIGURE SEVEN

#15

FOOT #17

#18

#16

#13 FOOT

#14

#12

#11

HEAD

#9

FOOT

#10

#19

FOOT

#20

CUT HOLES IN CLOTH AT

RAIL BOTH LOCATIONS