CAUTION: To prevent personal injury wear safety

glasses, protective clothing, and gloves when handling

refrigerant.

CAUTION: Back seating service valves are not

equipped with Schrader valves. Fully back seat (counter

clockwise) valve stem before removing gage port cap.

CAUTION: Federal regulations require that you do not

vent refrigerant to atmosphere. Recover during system

repair or final unit disposal.

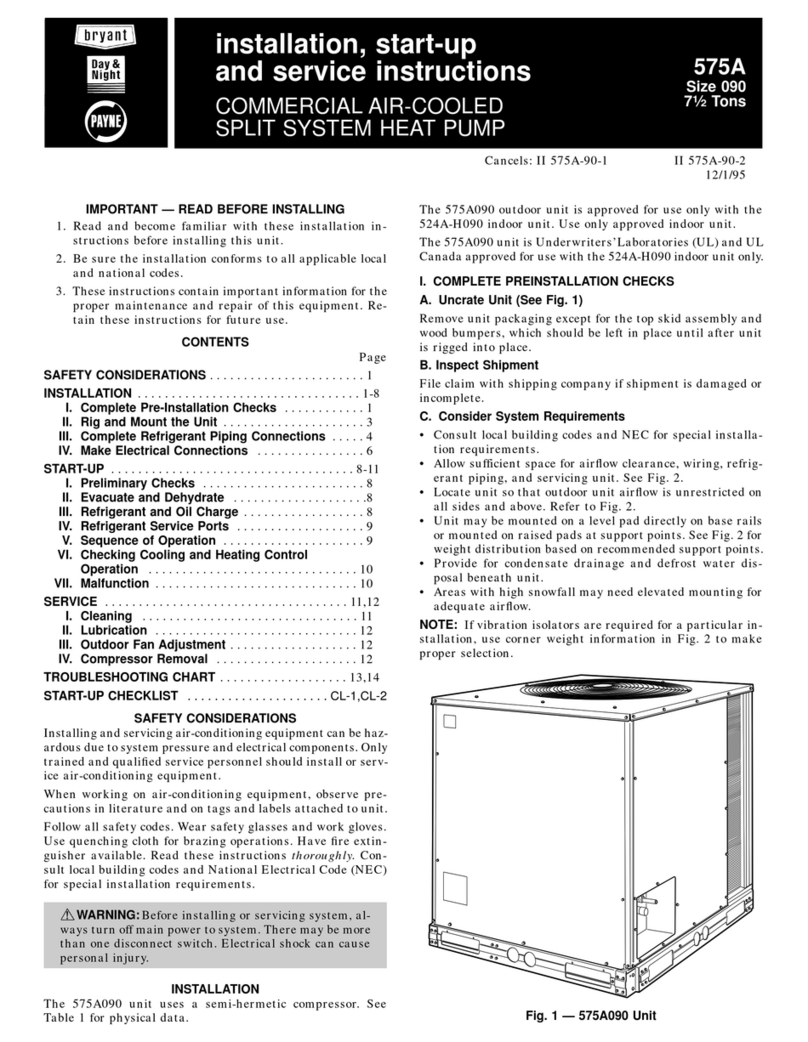

Follow these steps to properly start up the system:

1. Fully back seat (open) liquid and vapor service valves.

2. Unit is shipped with valve stem(s) front seated (closed) and

caps installed. Replace stem caps after system is opened to

refrigerant flow (back seated). Replace caps finger-tight and

tighten with wrench an additional 1/12 turn. Use a backup

wrench on valve body flats to prevent distortion of sheet

metal.

3. Close electrical disconnects to energize system.

4. Set room thermostat at desired temperature. Be sure set

point is below indoor ambient temperature.

5. Set room thermostat to HEAT or COOL and fan control to

ON or AUTO mode, as desired. Operate unit for 15

minutes. Check system refrigerant charge.

A. Sequence of Operation

NOTE: Defrost control board is equipped with a 5-minute lock-

out timer which may be initiated upon an interruption of power.

With power supplied to indoor and outdoor units, transformer is

energized.

COOLING

On a call for cooling, thermostat makes circuits R-O, R-Y, and

R-G. Circuit R-O energizes reversing valve, switching it to cooling

position. Circuit R-Y energizes contactor, starting outdoor fan

motor and compressor circuit. R-G energizes indoor unit blower

relay, starting indoor blower motor on high speed.

When thermostat is satisfied, contacts R-Y open, de-energizing the

contactor and blower relay. Compressor and motors should stop.

NOTE: If indoor unit is equipped with a time-delay relay circuit,

the blower runs an additional 90 sec to increase system efficiency.

HEATING

On a call for heating, thermostat makes circuits R-Y and R-G.

Circuit R-Y energizes contactor, starting outdoor fan motor and

compressor. Circuit R-G energizes indoor blower relay, starting

blower motor on high speed.

Should temperature in the dwelling continue to fall, R-W2 is made

through second-stage room thermostat. Circuit R-W2 energizes

supplemental electric heat. If outdoor temperature falls below

setting of outdoor thermostat (field-installed option), contacts

close to bring on an additional bank of supplemental electric heat.

When thermostat is satisfied, its contacts open, de-energizing

contactor and sequencer. All heaters and motors should stop after

all fan off delays.

QUIET SHIFT

Quiet Shift is a field-selectable defrost mode (factory set to OFF

position), which will eliminate occasional noise that could be

heard at the start of defrost cycle and restarting of heating cycle. It

is selected by placing DIP switch 3 (on defrost board) in ON

position.

When Quiet Shift switch is placed in ON position, and a defrost is

initiated, the following sequence of operation will occur. Revers-

ing valve will energize, compressor will turn off for 30 seconds,

then turn back on to complete defrost. At the start of heating cycle

after conclusion of defrost mode, reversing valve will de-energize,

the compressor will turn off for another 30 seconds, and the fan

will turn off for 40 seconds, before starting in the heating mode.

DEFROST

The defrost control is a time/temperature control which includes a

field-selectable time period (DIP switch 1 and 2 on the board)

between defrost cycles of 30, 60, 90, or 120 minutes (factory set at

90 minutes).

To initiate a forced defrost, two options are available depending on

the status of the defrost thermostat.

If defrost thermostat is closed, speedup pins (J1) must be shorted

by placing a flat head screw driver in between for 5 seconds and

releasing, to observe a complete defrost cycle. When the Quiet

Shift switch is selected, compressor will be turned off for two 30

second intervals during this complete defrost cycle, as explained

previously. When Quiet Shift switch is in factory default OFF

position, a normal and complete defrost cycle will be observed.

If defrost thermostat is in open position, and speedup pins are

shorted (with a flat head screw driver) for 5 seconds and released,

a short defrost cycle will be observed (actual length is dependent

upon the selected Quiet Shift position). When Quiet Shift switch is

in ON position, the length of defrost is 1 minute (30 seconds

compressor off period followed by 30 seconds of defrost with

compressor operation). On return to heating operation, compressor

will again turn off for an additional 30 seconds and the fan for 40

seconds. When the Quiet Shift is in OFF position, only a brief 30

second cycle will be observed.

If it is desirable to observe a complete defrost in warmer weather,

the thermostat must be closed as follows.

1. Turn off power to outdoor unit.

2. Disconnect outdoor fan motor lead from OF2 on control

board (See Fig. 19). Tape to prevent grounding.

3. Restart unit in heating mode, allowing frost to accumulate

on outdoor coil.

4. After a few minutes in heating mode, liquid line tempera-

ture should drop below closing point of defrost thermostat

(approximately 30°F).

NOTE: Unit will remain in defrost until defrost thermostat

reopens at approximately 80°F coil temperature at liquid line or

remainder of defrost cycle time.

5. Turn off power to outdoor and reconnect fan motor lead to

OF2 on control board after above forced defrost cycle.

XIV. CHECK CHARGE

A. Unit Charge

Factory charge is shown on unit rating plate. To check charge in

cooling mode, refer to Cooling Only Procedure. To check charge

in heating mode, refer to Heating Check Chart Procedure.

With unit operating, charge Puron units with liquid using a

commercial-type metering device in manifold hose. Charge refrig-

erant into suction line. Some refrigerant cylinders may contain a

dip tube that allows liquid refrigerant to flow from cylinder in

upright position. Check cylinder label for correct position to allow

liquid flow.

B. Cooling Only Procedure

NOTE: If subcooling charging conditions are not favorable,

charge must be weighed in accordance with unit rating plate ±0.6

oz/ft of 3/8-in. liquid line above or below 15 ft respectively.

—7—