Installation Instructions

TABLE OF CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . .1

MODEL NUMBER NOMENCLATURE AND

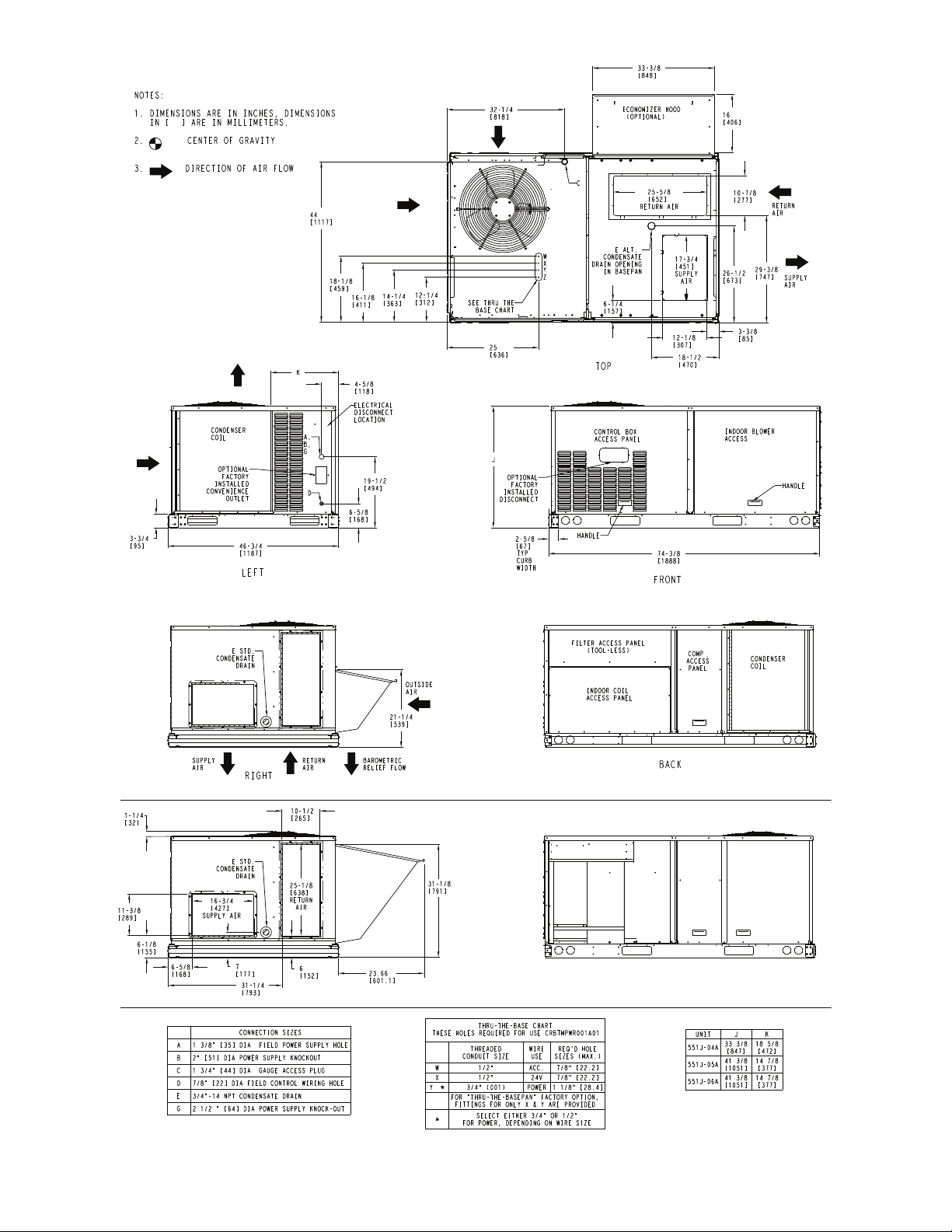

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Rated Indoor Airflow (cfm) . . . . . . . . . . . . . . . . . . . . . . .2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Jobsite Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Step 1 — Plan for Unit Location. . . . . . . . . . . . . . . . . . .6

• ROOF MOUNT

Step 2 — Plan for Sequence of Unit

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

• CURB-MOUNTED INSTALLATION

• PAD-MOUNTED INSTALLATION

• FRAME-MOUNTED INSTALLATION

Step 3 — Inspect Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Step 4 — Provide Unit Support . . . . . . . . . . . . . . . . . . .7

• ROOF CURB MOUNT

• SLAB MOUNT (HORIZONTAL UNITS ONLY)

• ALTERNATE UNIT SUPPORT (IN LIEU OF CURB OR

SLAB MOUNT)

Step 5 — Field Fabricate Ductwork . . . . . . . . . . . . . . .9

• UNITS WITH ACCESSORY ELECTRIC HEATERS

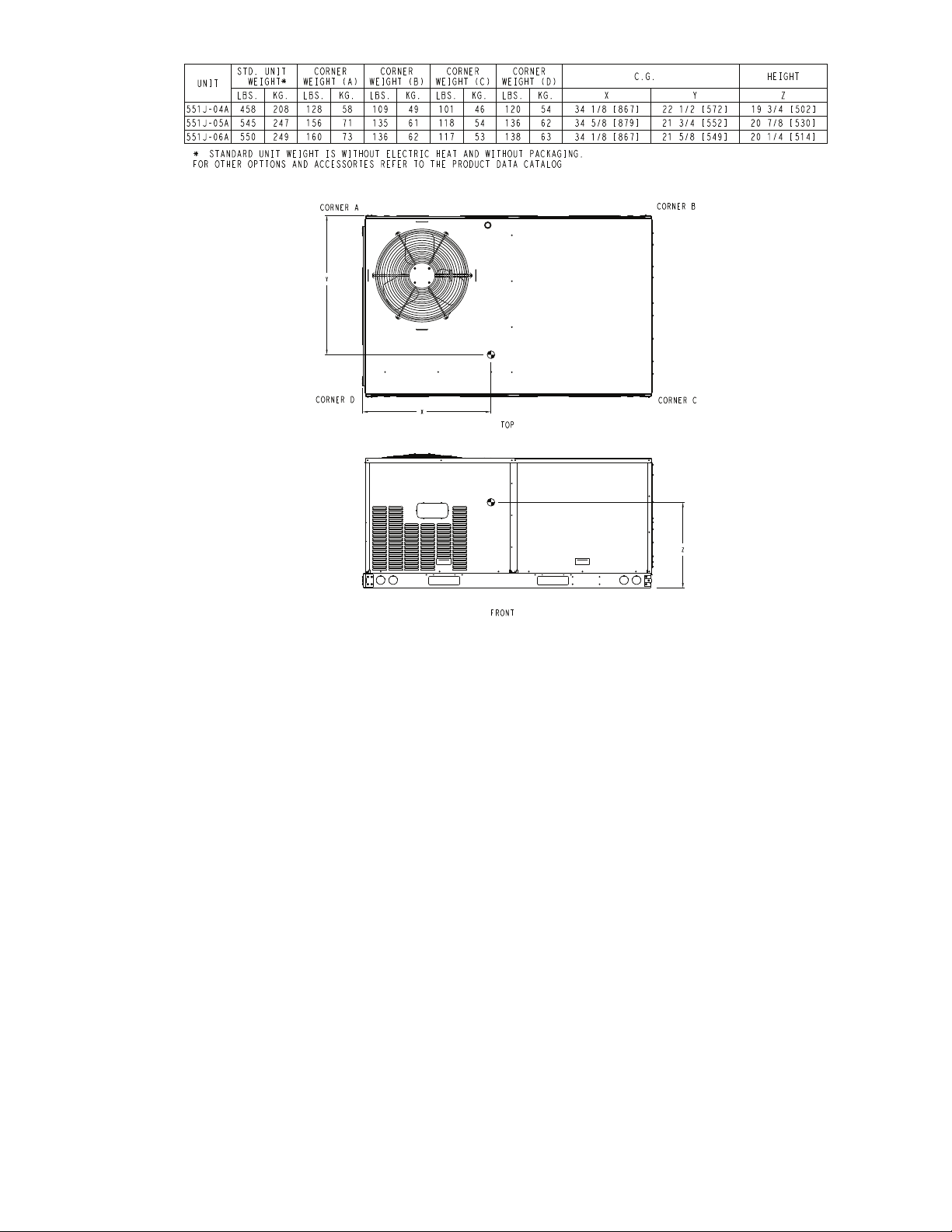

Step 6 — Rig and Place Unit . . . . . . . . . . . . . . . . . . . . . .9

• POSITIONING ON CURB

Step 7 — Convert to Horizontal and

Connect Ductwork (When Required) . . . . . . . . . . . . .10

Step 8 — Install Outside Air Hood . . . . . . . . . . . . . . .11

• ECONOMIZER AND TWO-POSITION DAMPER HOOD

PACKAGE REMOVAL AND SETUP (FACTORY

OPTION)

• ECONOMIZER AND TWO-POSITION HOOD

ASSEMBLY

Step 9 — Units with Hinged Panels Only . . . . . . . . .12

Step 10 — Install External Condensate Trap

and Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Step 11 — Make Electrical Connections . . . . . . . . .13

• FIELD POWER SUPPLY

• UNITS WITH FACTORY-INSTALLED DISCONNECT

• UNITS WITHOUT FACTORY-INSTALLED

DISCONNECT

•ALLUNITS

• CONVENIENCE OUTLETS

• FACTORY-OPTION THRU-BASE CONNECTIONS

(ELECTRICAL CONNECTIONS)

• UNITS WITHOUT THRU-BASE CONNECTIONS

(ELECTRICAL CONNECTIONS)

• FIELD CONTROL WIRING

• THERMOSTAT

• HEAT ANTICIPATOR SETTINGS

• ELECTRIC HEATERS

•PERFECTHUMIDITY™CONTROL CONNECTIONS

• CONTROL AND POWER WIRING DIAGRAMS

• ECONOMI$ER®(FACTORY OPTION)

• SMOKE DETECTORS

• RTU OPEN CONTROLLER (FACTORY OPTION)

• CONTROLLER OPTIONS

Step 12 — Adjust Factory-Installed Options . . . . .40

• SMOKE DETECTORS

• ECONOMI$ER IV OCCUPANCY SWITCH

Step 13 — Install Accessories . . . . . . . . . . . . . . . . . . .40

Step 14 — Check Belt Tension. . . . . . . . . . . . . . . . . . .40

Pre-Start and Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . .40

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . CL-1

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, mainte-

nance, or use can cause explosion, fire, electrical shock or other

conditions which may cause personal injury or property damage.

Consult a qualified installer, service agency, or your distributor or

branch for information or assistance. The qualified installer or

agency must use factory-authorized kits or accessories when mod-

ifying this product. Refer to the individual instructions packaged

with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloths for brazing operations and have a fire extin-

guisher available. Read these instructions thoroughly and follow

all warnings or cautions attached to the unit. Consult local build-

ing codes and appropriate national electrical codes (in USA,

ANSI/NFPA70, National Electrical Code (NEC); in Canada, CSA

C22.1) for special requirements.

It is important to recognize safety information. This is the safety-

alert symbol . When you see this symbol on the unit and in in-

structions or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION,

and NOTE. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices, which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

551J 04-06

Single Package Rooftop Cooling Only with

Puron®(R-410A) Refrigerant