Safety

2014-01-27 / DIS 118_58300000157376_ARA_EN_C Repair Instructions Consumer Products BGS5 Page 5 of 34

2.3.2 Measures to be taken after each repair

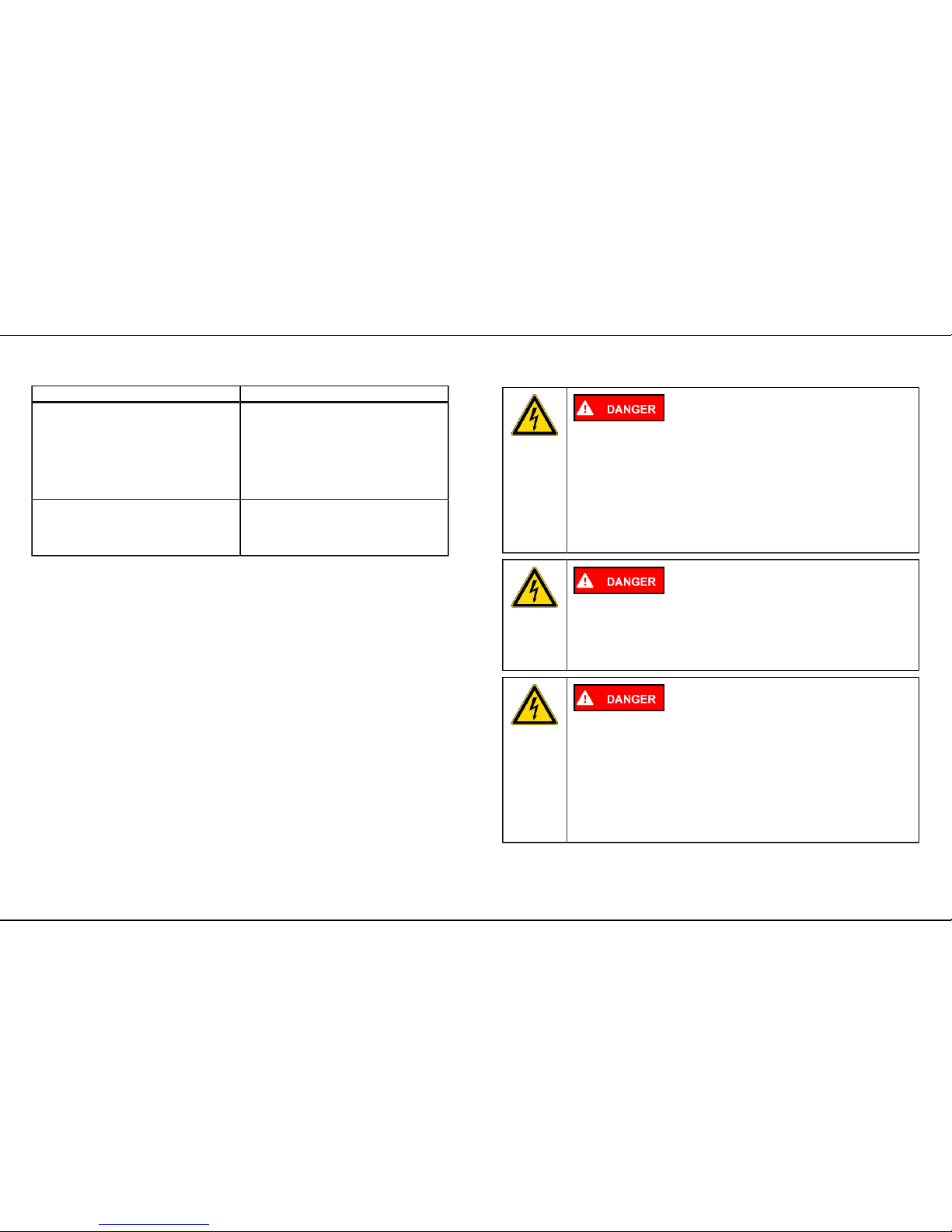

State of the appliance Measures

Appliance has been repaired and is

functionally reliable.

• Run tests in accordance with VDE

0701 or comparable national regula-

tions.

• Conduct a performance test.

• Document repair work, tests, mea-

sured values and functional reliabili-

ty.

Appliance is still defective and not func-

tionally reliable.

• Clearly identify appliance as "not

functionally reliable".

• Inform customer in writing about the

lack of functional safety.

Table 4: Measures to be taken after each repair

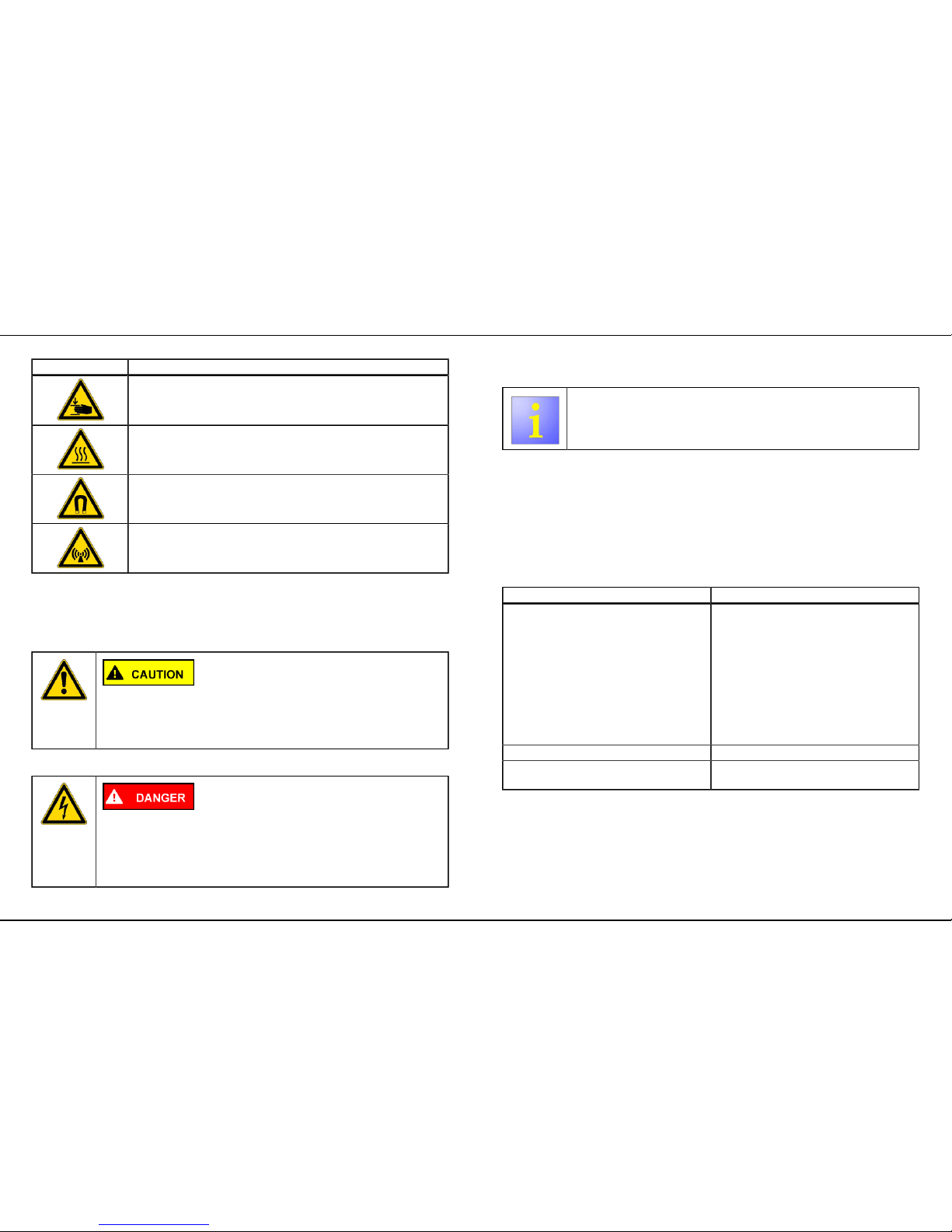

2.4 Basic warning instructions

Exposed, live components!

Death from electric shock.

► Disconnect the appliance from the power supply.

► Do not touch housing, frame or components.

► If running tests while the power is on, always use a residual

current circuit-breaker.

► Ensure that the resistance of the protective conductor does not

exceed the standardised value.

Discharge current of charged capacitors!

Death from electric shock. Risk of injury from startle response.

► Disconnect the appliance from the power supply.

► Discharge capacitors.

Exposed, defective components live!

Death from electric shock.

► Disconnect the appliance from the power supply.

► Do not touch housing, frame or components.

► If running tests while the power is on, always use a residual

current circuit-breaker.

► Ensure that the resistance of the protective conductor does not

exceed the standardised value.