9

BÜCHI Vacuum System B-180 4 Putting into operation

The adhesive labels supplied are for labelling the controller, rotary

evaporator and separator, making it easy to identify which rotary

evaporator is connected to which Vacuum Controller via which

separator. Accordingly, the corresponding components are to

be given e.g. the same number.

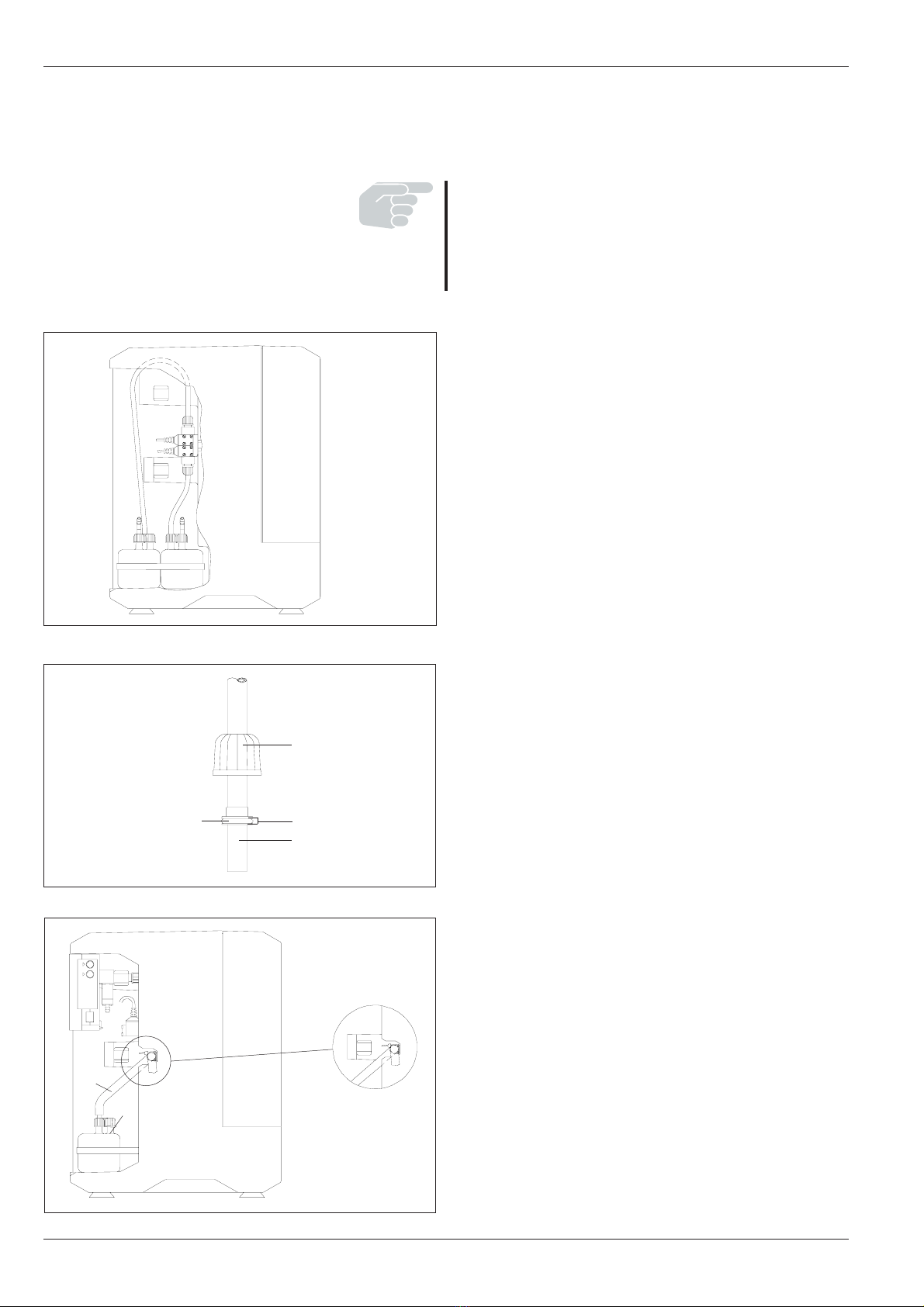

The B-180 can be controlled externally by the following

apparatuses:

• Vacuum Controller B-720

• Vacuum Controller B-168

• Rotavapor R-134

• Rotavapor R-144

To control the apparatus externally, the control cable supplied (order

code 36493) has to be connected to the external controller (B-

720, B-168, R-134 or R-144), the connection being made between

V1 on the B-180 and V on the controller. The control cable supplied

(order code 31238) has to be used if the external Vacuum Controller

is not a B-720.

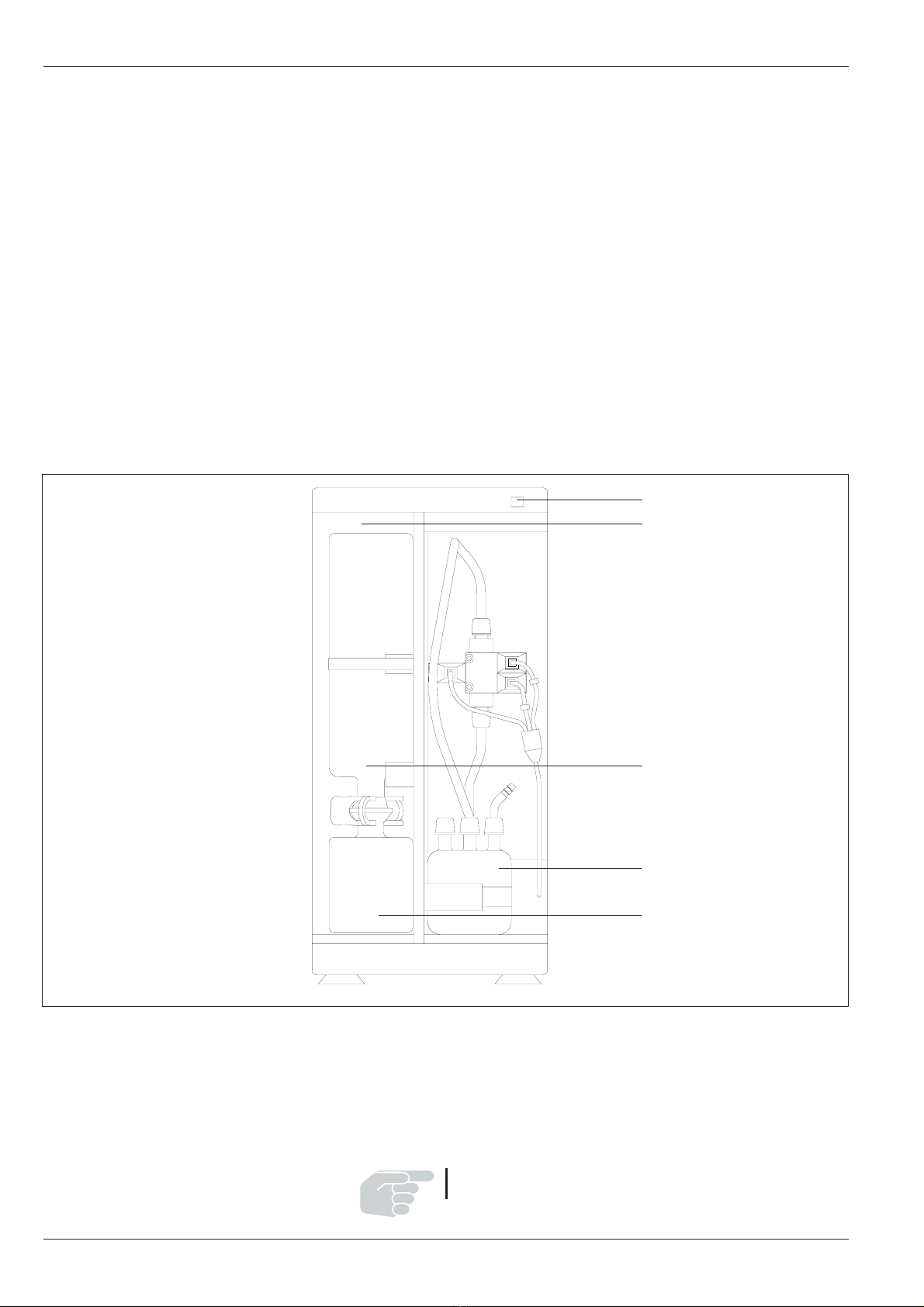

4.4 Tube connections

• The apparatus must never be operated without an exhaust tube.

• The exhaust tube must not point towards hot objects or objects

which produce sparks (Danger: flammable solvent vapors).

Whenever possible, the exhaust tube should be led into a hood

to ensure the solvent vapors do not come into the room.

• Care must be taken to ensure that no tubes are pinched (kinks,

apparatus standing on tube, etc.)

• Brittle tubes must be changed.

Cooling water:

Plug the cooling water valve into the socket . Let the cooling

water run through the condenser of the B-180 ( = inlet,

= outlet). The same cooling water can then be fed into the first

Rotavapor . If the cooling water is still cold enough, it can also

be used for a second Rotavapor . If the cooling water has

become too warm after the first Rotavapor, the second Rotavapor

must be cooled via a separate cooling water connector. Finally,

the cooling water is fed into the discharge .

The cooling water flow must be reduced to 30-40 l/h (Cooling

water valve, needle valve).

!

Figure 5: Cooling water tubing