3

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not take into account any unforeseen

circumstances and events which occur during installation, oper-

ation and maintenance. The operator is responsible for observing

the location-specic safety regulations, also with reference to the

personnel.

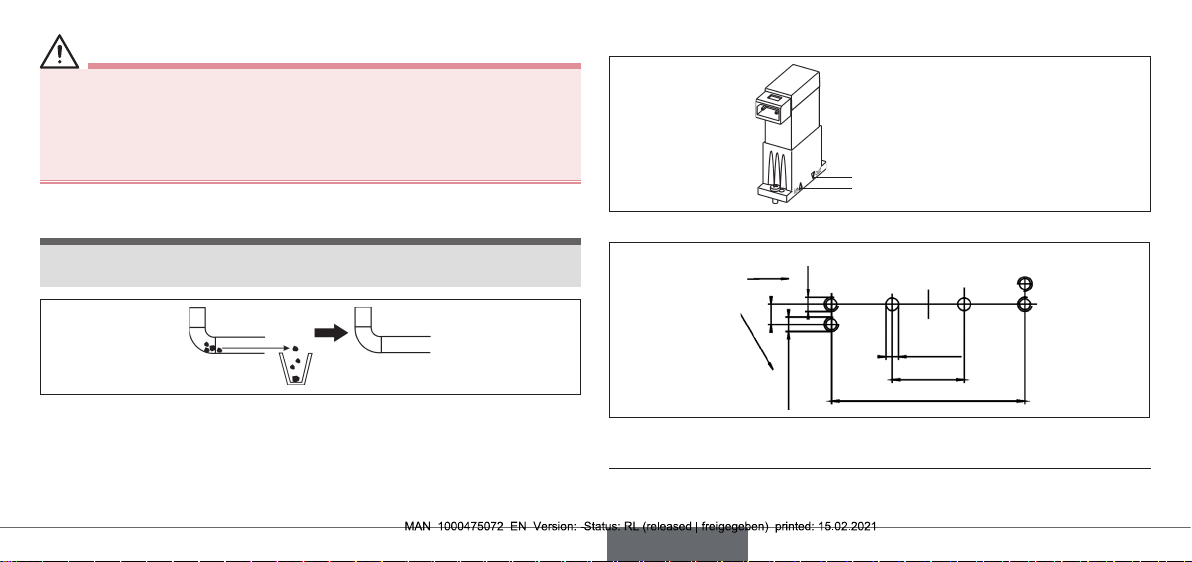

Risk of injury due to high pressure and escaping medium.

▶Before working on the device or system, switch o the pressure.

Exhaust or empty the lines.

Risk of injury due to electric shock.

▶Before working on the device or system, switch o the power

supply. Secure against reactivation.

▶Observe the applicable accident prevention and safety regula-

tions for electrical devices.

Risk of burns or re from hot device surfaces due to longer duty

cycles.

▶Only touch the device when wearing protective gloves.

▶Keep the device away from highly ammable substances and

media.

2 INTENDED USE

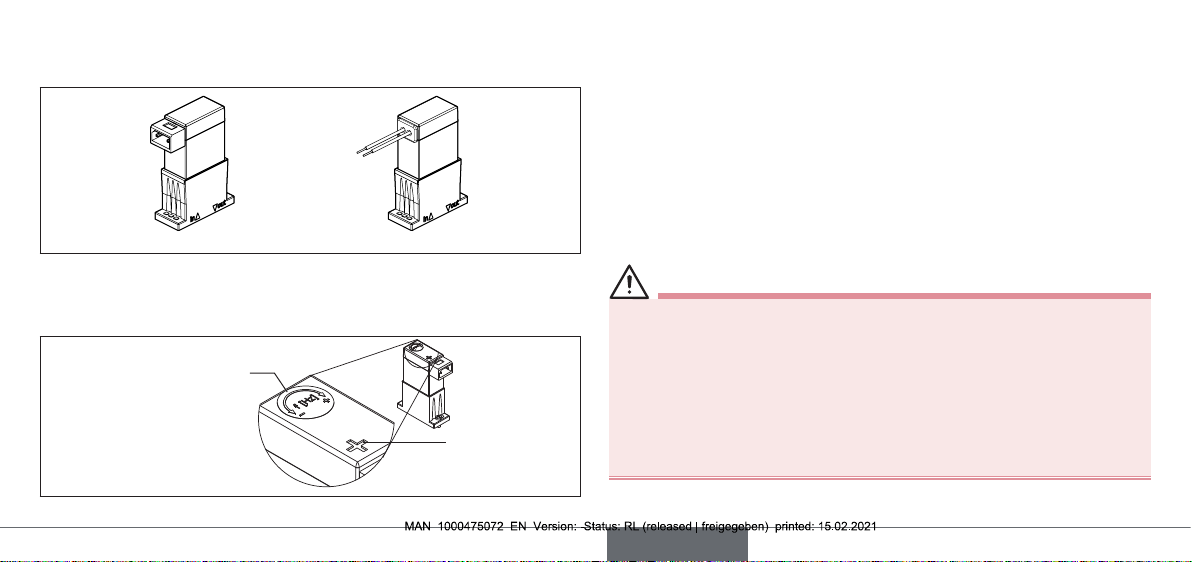

Micro diaphragm pump Type7604 solely serves as a micro dia-

phragm pump for the media permitted as per the data sheet.

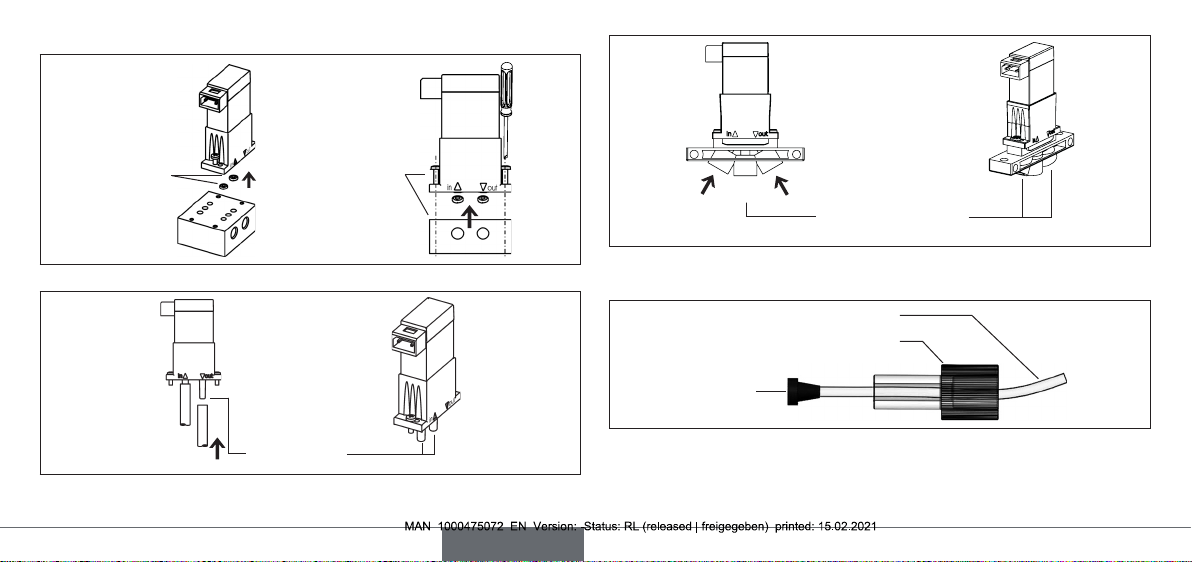

▶Use the device only in conjunction with third-party devices and

components recommended and authorized by Bürkert.

▶Prerequisites for safe and trouble-free operation include correct

transportation, correct storage, installation, start-up, operation

and maintenance.

▶Observe the permissible data, operating conditions and condi-

tions of use of the respective devices or products. These spec-

ications can be found in the contract documents, operating

instructions and on the type label.

▶Use the device only as intended. Non-intended use of the

device may be dangerous to people, nearby equipment and the

environment.

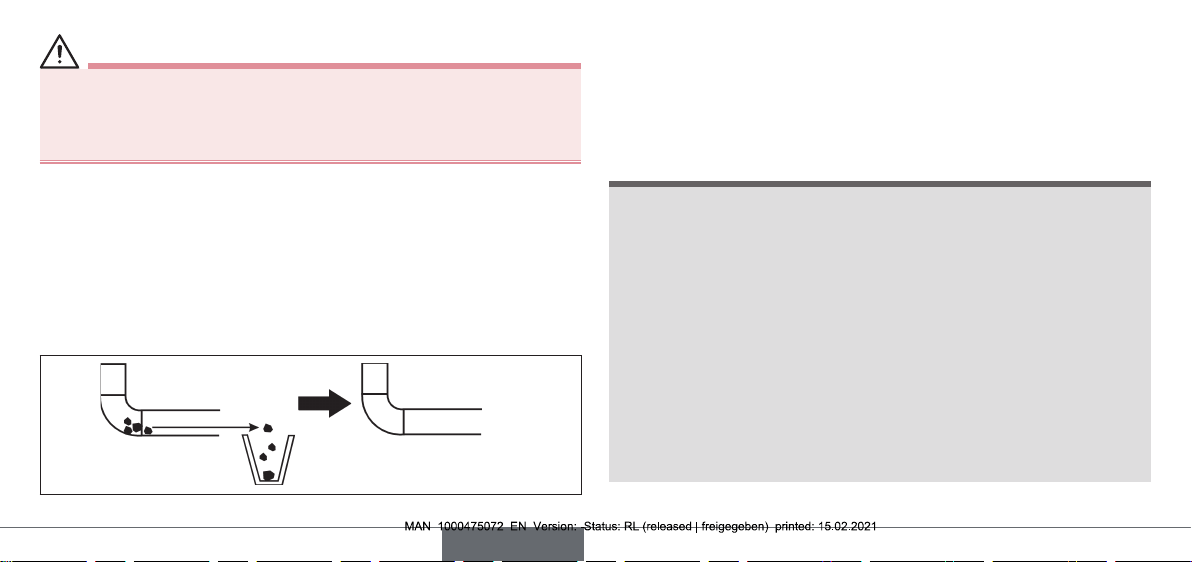

▶Do not operate the device without suitable ltration of the input

medium.

2.1 Denition of terms

Term Denition for these instructions

Device Micro diaphragm pump Type7604

English