3

8 INSTALLATION ............................................................................................15

8.1 Safety instructions ...................................................................15

8.2 Before installation ....................................................................15

8.3 Installation .................................................................................18

8.4 Disassembly..............................................................................20

9 ELECTRICAL CONNECTION ................................................................21

10 MAINTENANCE, CLEANING ................................................................21

10.1 Safety instructions ...................................................................21

10.2 Maintenance Work ..................................................................21

11 REPAIRS.........................................................................................................22

11.1 Safety instructions ...................................................................22

11.2 Replacing the diaphragm ......................................................23

12 MALFUNCTIONS ........................................................................................25

13 SPARE PARTS.............................................................................................26

13.1 Order table ................................................................................27

14 PACKAGING AND TRANSPORT ........................................................27

15 STORAGE ......................................................................................................28

16 DISPOSAL .....................................................................................................28

Piston operated diaphragm valves type 2030, 2031, 2031 K, 2032, 2033, 2037

1 OPERATING INSTRUCTIONS ................................................................4

1.1 Definition of the Term “Device”...............................................4

1.2 Symbols .......................................................................................4

2 AUTHORIZED USE ......................................................................................5

2.1 Restrictions .................................................................................5

3 BASIC SAFETY INSTRUCTIONS ..........................................................6

4 GENERAL INFORMATION ........................................................................7

4.1 Contact Addresses ...................................................................7

4.2 Warranty ......................................................................................7

4.3 Information on the Internet ......................................................7

5 SYSTEM DESCRIPTION ............................................................................7

5.1 General Description ..................................................................7

5.2 Intended Application Area .......................................................7

5.3 Conformity ...................................................................................7

5.4 Standards .................................................................................... 7

6 TECHNICAL DATA ........................................................................................8

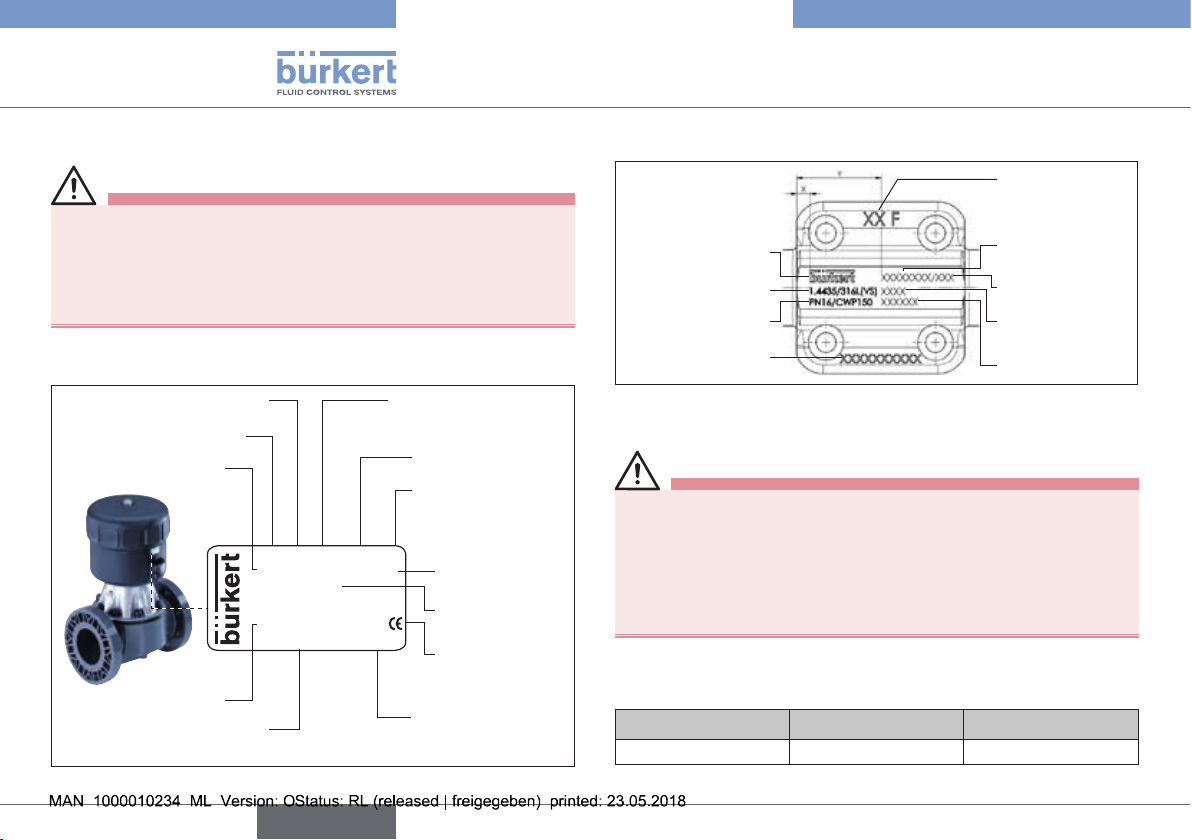

6.1 Inscription on the type label ....................................................8

6.2 Labeling of the forged bodies ................................................ 8

6.3 Operating Conditions ...............................................................8

6.4 General Technical Data..........................................................12

7 STRUCTURE AND FUNCTION............................................................12

7.1 Structure ....................................................................................12

7.2 Function .....................................................................................14

english

Type 2030, 2031, 2031 K, 2032,

2033, 2037