3.1.3 Peel Point Lateral Adjustment......................................................................... 3-3

3.1.4 Label Spool Threading and Lateral Positioning.............................................. 3-4

3.1.5 Despool Brake Adjustment.............................................................................. 3-6

3.2 Labeler Connector Panel..................................................................................... 3-7

3.3 Wide Labeler Guidelines (BK731-2WL & UBK-731-WL)............................... 3-8

3.3.1 Importance of the Right & Left Side Guides................................................... 3-8

3.3.2 The Tabber Skidbar Assembly......................................................................... 3-9

3.3.3 Wide Label Pressure Roller........................................................................... 3-11

3.3.4 Label Backer Tension.................................................................................... 3-12

3.3.5 Idler Roller Setup........................................................................................... 3-13

3.3.6 Fanfold Supply Tray Assembly (p/n 9102031A)........................................... 3-14

3.3.7 Independent Nip Roller Height Adjustment.................................................. 3-15

4.0 User Interface ........................................................................................4-0

4.1 Tabber/Labeler Keypad Interface...................................................................... 4-1

4.2 Keypad Setup Menu............................................................................................. 4-2

4.2.1 Front or Back Product Sensor Selection.......................................................... 4-2

4.2.2 Adjustment of the Product Sensor Position..................................................... 4-3

4.2.3 Production Counter Resetting.......................................................................... 4-3

4.2.4 Software Version ............................................................................................. 4-4

4.2.5 Factory Reset ................................................................................................... 4-4

4.2.6 Life Count Display........................................................................................... 4-4

4.2.7 Form Size Error................................................................................................ 4-5

4.2.8 Displaying Metric Units on the Operator Keypad........................................... 4-5

4.3 Keypad Test Menu ............................................................................................... 4-6

4.4 Keypad Position Menu......................................................................................... 4-8

4.4.1 Label Spacing Option ...................................................................................... 4-8

4.4.2 Number of Labels ............................................................................................ 4-9

4.4.3 Product Length Entry....................................................................................... 4-9

4.4.4 Manual Label Position................................................................................... 4-10

4.4.5 Keypad Labels Menu..................................................................................... 4-11

4.4.6 Label Pitch Auto and Manual Setting............................................................ 4-11

4.4.7 Type of Label Setting .................................................................................... 4-13

4.4.8 Peel Point Sensor Adjustment........................................................................ 4-13

4.4.9 Peel Point Sensor Nudge Factor .................................................................... 4-14

4.5 Operational Controls.......................................................................................... 4-14

4.5.1 Online/Offline Status..................................................................................... 4-14

4.5.2 Product Count, Production Rate, and Belt Speed Display............................. 4-15

4.5.3 Error Conditions ............................................................................................ 4-15

4.6 Maintenance Schedule........................................................................................ 4-16

Appendix A – Assembly Drawings

Appendix B – Electrical Drawings

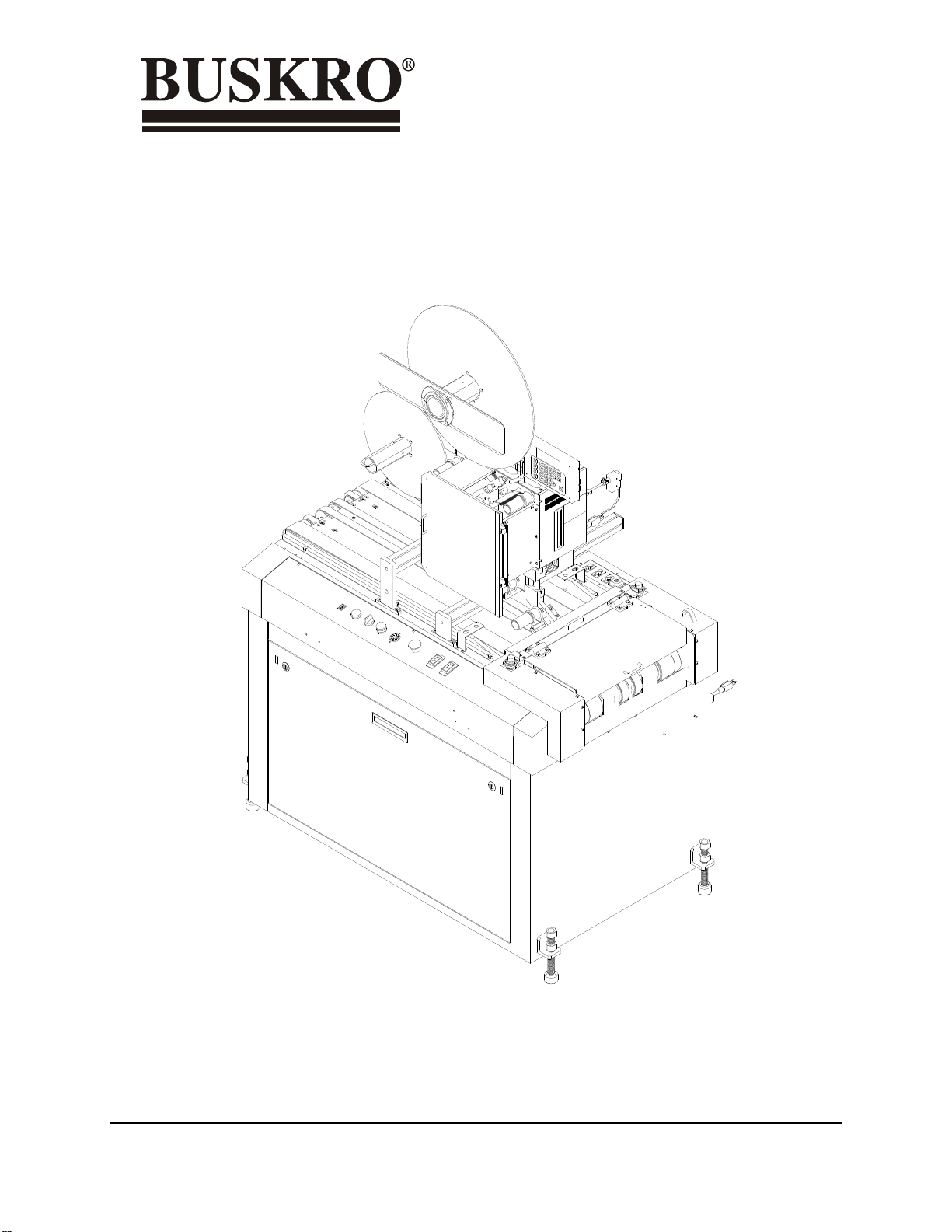

Buskro Ltd. BK730-2 Tabber