4

Safety Instructions

DANGER! Check that the spring

compressor is in sound condition and

good workingorder before each use; Take

immediate action to repair or replace

damaged parts.

WARNING! Only operate on a level and

stable surface and never use on soft

ground where the spring compressor is

likely to “sink” whilst in operation.

NEVER STAND ON THE SPRING

COMPRESSOR: The spring compressor is

not designed for this purpose.

DO NOT dismantle or tamper with the

spring compressor, as this may be

dangerous and will invalidate the warranty.

•If a problem with the spring compressor

is experienced or suspected stop using

the spring compressor immediately and

contact your distributor for repair.

•Do not attempt to compress a load that

exceeds the rated capacity of the spring

compressor.

•Regularly inspect and lubricate the spring

compressor, ensuring that it is in good

working order and condition.

•Always ensure that the work area

is clean and tidy, free from unrelated

materials and has adequate lighting.

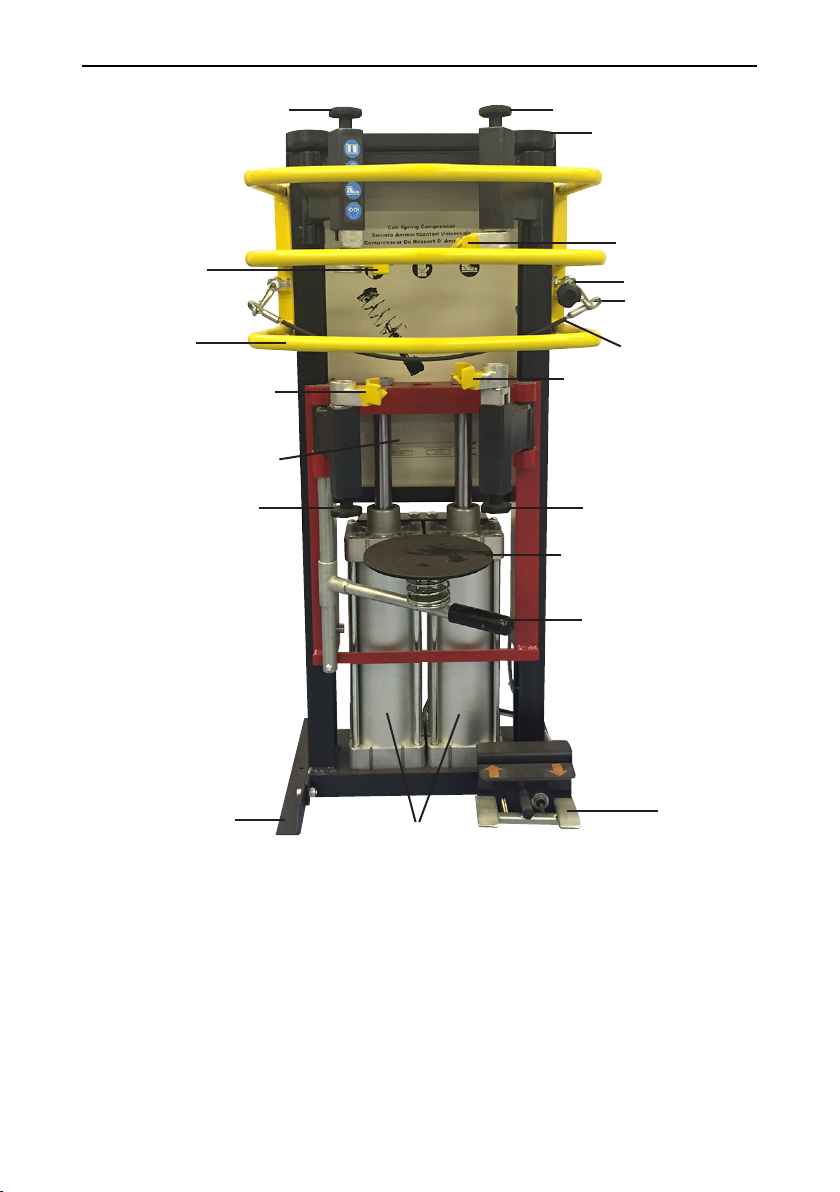

•Keep hands, limbs etc. clear of moving

parts during operation; Never place

any-thing inside the safety cage during

operation

•Clean and stow the spring compressor

correctly, with the ram in the down position,

DO NOT leave it extended; ensure storage

area is dry.

•Failure to follow the warnings in this

manual, may result in personal injury and/

or property damage.

•Always ensure that the clamps are

correctly supporting the spring; Oset

loads can damage the machine and the

spring, and may cause it to ‘eject’ from the

spring compressor.

•Before each operation, check for signs

of cracked welds, loose or missing bolts

or any other structural damage; Do not

operate if any of these conditions exist.

Have repairs made only by authorised

service centre.

•Components of this spring compressor

are specially designed to withstand the

rated capacity. Do not substitute bolts,

pins, or any other components.

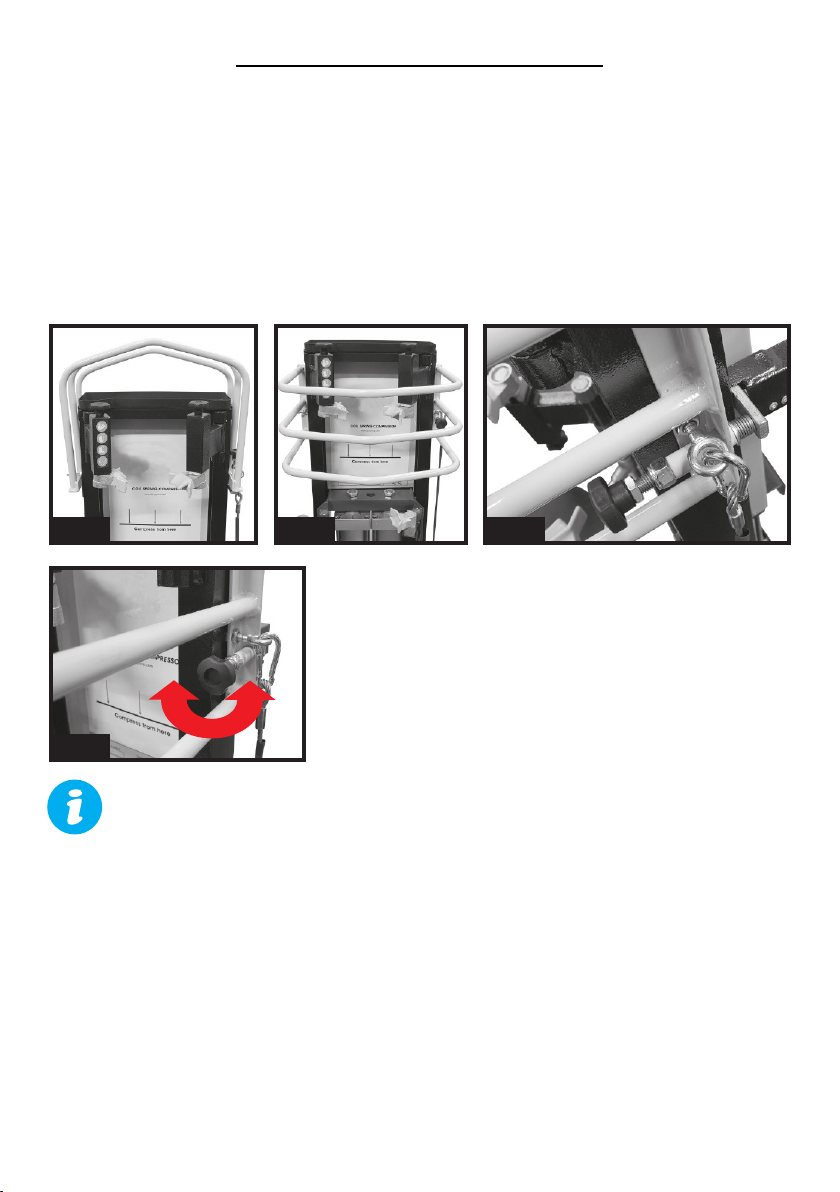

•DO NOT remove the safety cable or

safety cage during operation.

• In extreme circumstances, parts being

compressed may shatter or eject from

the compressor; It is the operators

responsibility to always use the safety

cable, safety cage and adequate personal

protective equipment such as eye

protection, safety boots / shoes, gloves

and heavy protective clothing, when

operating this spring compressor.

•If the spring compressor appears to be

damaged in any way, is found to be badly

worn, or operates abnormally IT SHOULD

BE REMOVED FROM SERVICE until

necessary repairs are made by an

authorised service centre.

•Prior to applying the load, be sure

that the damper and spring are aligned

correctly.