4.3 Air-pumping Operation

4.3.1 Connect the power supply according to 4.1 power supply instructions for Power

Supply Use or 4.2 Instructions of External 12V Battery Application.

4.3.2 Find out the position of the adjustable pressure gauge and set the ideal pressure

value through the knob of the pressure gauge. A clockwise rotating pressure

value increases and a counterclockwise rotating pressure value decreases.

WARNING: The maximum pressure of this compressor is 300bar (4350psi). When

setting the pressure of the adjustable pressure gauge, it should not exceed 300bar

(4350psi). Otherwise, it will possibly damage the machine or risk explosion and

even cause injury or death.

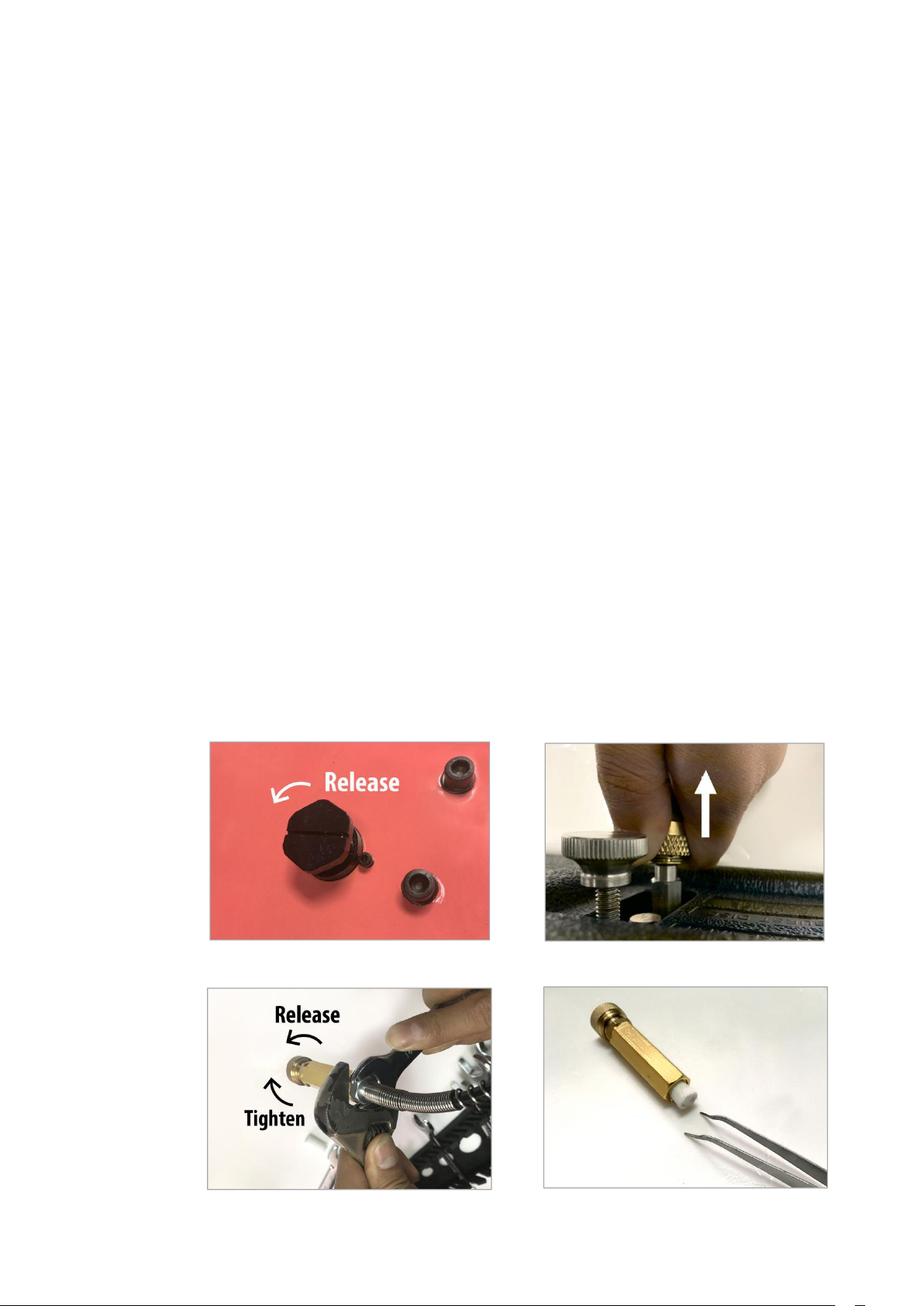

4.3.3 Connect the female quick connectors from both side of output hose to the male

connectors from compressor and pumped equipment, the one with filter connects

to compressor (Figure 4.3.3).

Note: Check whether the connection between the female quick connectors and

the male connectors are secure.

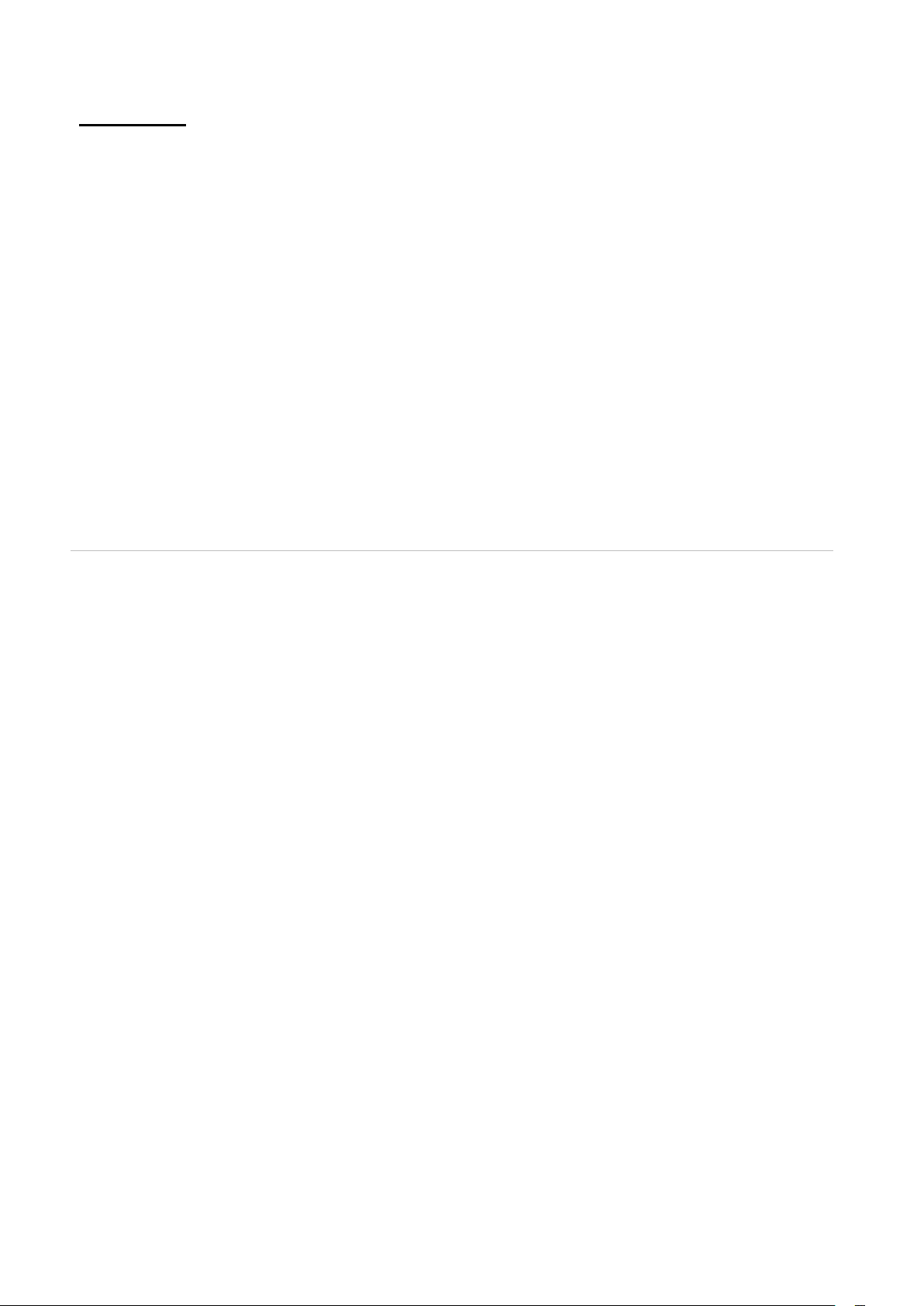

4.3.4 Turn and tighten the release button clockwise, and ensure that the inflated

equipment does not leak.

Note: If you want to pump a completely airless PCP air rifle, you need to load it first

and then start to pump it. Please refer to your air rifle instructions for further help.

4.3.5 Press ON/OFF button, the light changes to green, the compressor starts to work.

Note: You can stop pumping at any time by pressing the start button. If you need

to restart the compressor, you need to release the gas in the output hose,

referencing to 4.3.6.

4.3.6 When the pressure reaches the set pressure value, the compressor will stop

automatically. The buzzer emits a reminder sound (low-frequency sound),

Note: The fan of the compressor will continue working to cool down. When the

temperature display of the compressor is lower than 45°C, the fan will stop working.

4.3.7 Release the air in the hose by rotating the counterclockwise (Figure 4.3.7). When

the pressure gauge indicates 0psi/bar, the air in the hose is released completely.

Note: When loosening the release button, there may be gas or liquid ejecting at

high speed from the air release button of the compressor. Please keep your

fingers/hands/eyes away from this part as far as possible.

4.3.8 Remove the pumped equipment and pull out 3-prong power cord or straddle

clamp.