3

CONTENTS

WELCOME.......................................................................... 2

Plow Registration .......................................................... 2

SnowDogg®Plow Owner Information........................... 3

WARNINGS ........................................................................ 4

IMPORTANT APPLICATION NOTICE .................................. 5

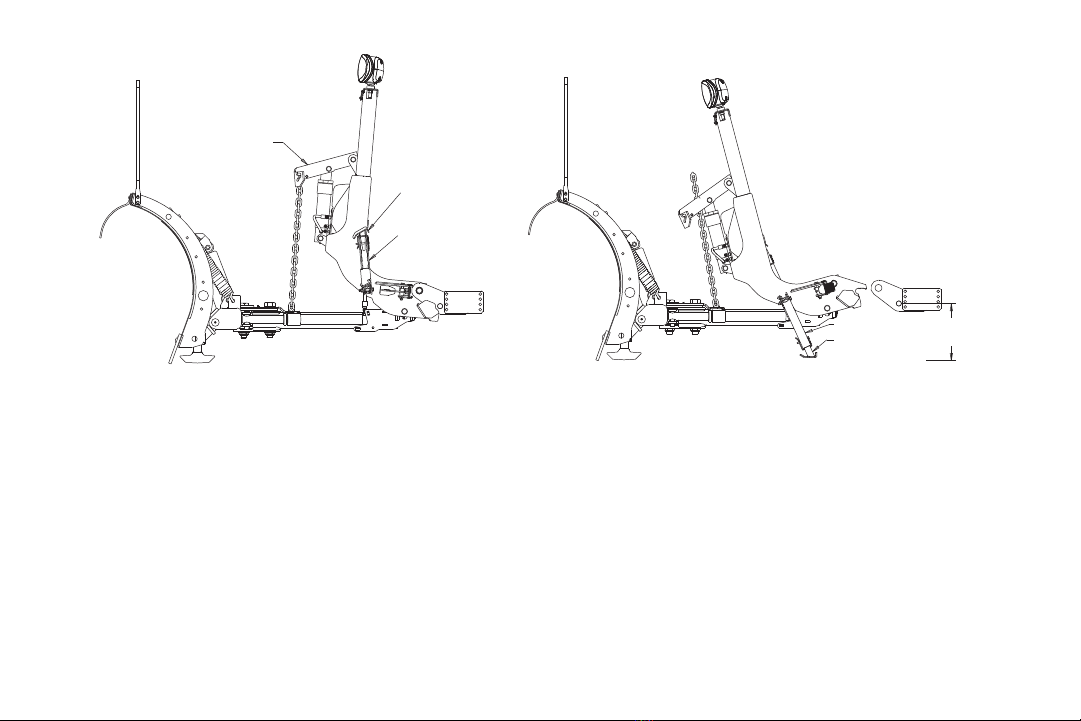

MOUNTING ........................................................................ 6

STRAIGHT BLADE PLOW OPERATION............................... 7

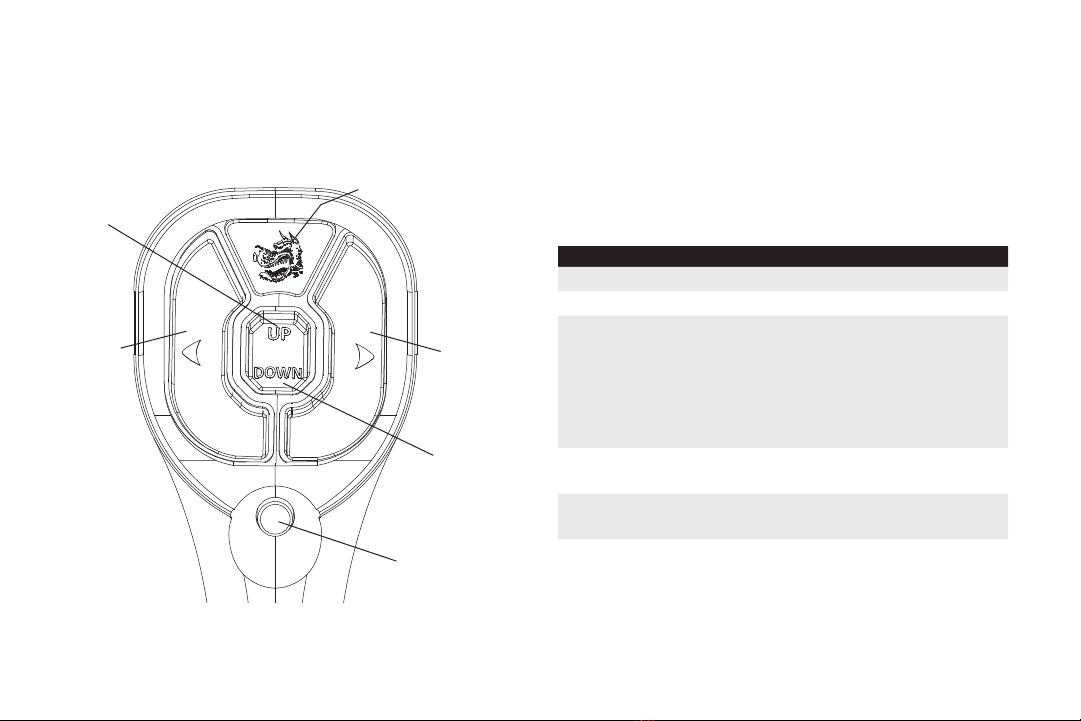

Straight Blade Controls ................................................. 7

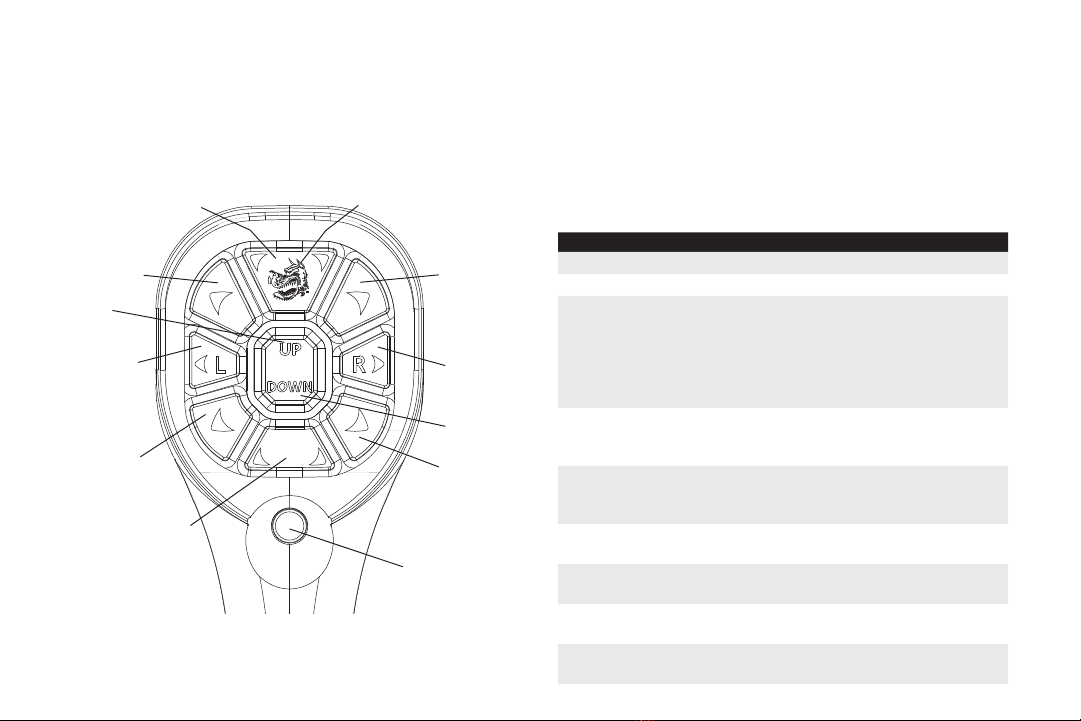

V Blade Plow Operation ............................................... 10

MAINTENANCE ............................................................... 14

Preparing Your Plow for Storage ................................. 14

Preparing Your Plow for the Season............................ 14

Preparing Your Truck for the Season........................... 15

In-Season Maintenance............................................... 16

SNOW PLOW OPERATION................................................ 18

Transporting Your Plow ............................................... 18

Plow Smart .................................................................. 19

Tactics for Effective Plowing ....................................... 19

Windrowing ............................................................... 19

Backdragging............................................................ 20

Stacking.................................................................... 20

Other Tips ................................................................. 20

COMMON SERVICE/MAINTENANCE ITEMS .................... 22

TROUBLESHOOTING ........................................................ 23

Lighting/Electrical ....................................................... 23

General Hydraulics ...................................................... 23

Straight Blade.............................................................. 25

V Plow .......................................................................... 26