C-Tech EDG-1S User manual

I

NON-NUCLEAR SOIL ELECTRICAL DENSITY GAUGE EDG-1S

I

CONTENTS

I. Introduction .....................................................................................................................................................1

II. Is EDG Safe to Use?......................................................................................................................................1

III. Introduction to the EDG Process ....................................................................................................................1

IV. Components of the EDG Units .......................................................................................................................2

V. The EDG Process in Depth .............................................................................................................................3

VI. Making a Soil Model .......................................................................................................................................5

VII. To create a Soil Model ....................................................................................................................................6

VIII. Associating a Soil Model With a Project ..................................................................................................... 12

IX. Project test & view the results .................................................................................................................... 15

X. Features Setup ............................................................................................................................................ 17

XI. Notice ........................................................................................................................................................... 18

XII. EDG Technical Specifications ..................................................................................................................... 18

XIII. Soil Density ................................................................................................................................................... 19

XIV. EDG Error Messages and Warnings ............................................................................................................ 20

Quality Warranty .................................................................................................................................................. 23

Packing List .......................................................................................................................................................... 24

-1 -

I. Introduction

Electrical Density Gauge (EDG) is capable of providing accurate readings of soil density, moisture

content, and percent compaction on soils typically used for roads and foundations. The precision by

which the EDG can determine these physical parameters depends highly upon you, the operator.

Reading and understanding the contents of this manual is a very important step toward utilizing EDG

to its maximum potential.

Please review the packing list of items that constitute the complete EDG, and that were shipped to

you. If there is any doubt as to whether you received the complete set of items, please contact the

factory immediately.

The following will give you an overview of the EDG process and help you understand the more detailed

steps found later in the manual.

II. Is EDG Safe To Use?

Absolutely! There is far less measuring energy present when using EDG than when you are using a

cell phone.

III. Introduction to the EDG Process

The EDG process introduces some new terminology with which you need to be familiar.

A Soil Model is a combination of electrical soil data and user-entered physical soil data. The Soil

Model provides the basis for testing a specific soil type within an area of similar soil characteristics.

To make a Soil Model, several electrical signatures are acquired using the EDG at different Test Spots

(the Test Spots for a Soil Model are called Soil Tests). For each Test Spot that an electrical signature

is acquired, a Sand Cone test is also performed to obtain physical wet density, dry density, and

percent moisture information. A proctor test can optionally be performed to determine the maximum

dry density. The physical information determined by the Sand Cone and Proctor Mold laboratory tests

are entered into the EDG unit, thereby tying electrical signature information to physical data.

At least three Test Spots (Soil Tests) are required to create a Soil Model; more Test Spots make for a

more representative Soil Model. Further, Test Spots that exhibit a broad range of density and

-2 -

moisture content make for more accurate Soil Models.

Once the Soil Model has been created, the EDG is ready for testing at a Job Site. A Job Site is an area

of similar soil characteristics in which the user wishes to determine the physical characteristics of

the soil.

A single Soil Model is generally created for each different Job Site. Once a Soil Model has been

created that accurately models the Job Site, the soil characteristics of any Test Spot within the Job

Site can be accurately and quickly determined by the EDG by performing a Field Test.

A Field Test is electrical soil data at a particular Test Spot that is fed into the Soil Model to produce

physical soil characteristics.

IV. Components of the EDG Unit

EDG Console/Computer, Electrical Soil Measurement Sensor, Dart Template, Hammer, Cables/Clips

for Soil Measurement Sensor, Soil Darts, Battery Charger, Temperature Probe, Break-Out Cable.

Components:

EDG Console/Computer:

The EDG unit contains a computer that applies mathematical formulas to determine the physical

characteristics of the soil. The computer also contains memory that remains intact after the EDG has

been powered off; this memory is used to save Soil Models and Job Site data. The EDG console has

an LCD display that is used to provide visual information to the user and a touch screen that allows

the user to enter information into the EDG unit.

Soil Electrical Measurement Sensor:

The soil sensor is connected to the Soil Darts and EDG Computer using cables and clips. Then the

Soil Sensor gathers electrical information about the soil under test and transfers the information to

the EDG computer.

The Soil Sensor requires no maintenance or adjustment, so there is no need to open the enclosure.

Keep it clean and dry when using it. It is an electronic circuit, so treat it with the same respect you

use with your cell phone. If the Sensor Pins become loose, hold the pin with pliers while tightening

-3 -

the nut against the enclosure.

Soil Darts:

To get electrical data from the soil, 4 Soil Darts are pounded into the ground with a hammer. A

template is provided to accurately position the Soil Darts. The Soil Darts are machined from stainless

steel, and are expected to last many years. If the conical end becomes flattened from hitting too

many rocks, either file or grind off any mushrooming at the point to maintain a conical shape to the

Dart. If the top end of the Dart becomes damaged or starts to crack from excessive hammering, file

off the damaged part to avoid having pieces of steel flying off when driving in the Dart. Always wear

safety glasses when hammering in the Soil Darts.

Temperature Probe:

Temperature Probe: The temperature probe attaches to the panel receptacle on the soil sensor.

When performing EDG testing, the temperature probe should be placed into the soil. The soil

temperature is an important variable in accurate EDG testing. The EDG computer uses the

temperature information to perform temperature compensation, resulting in more accurate EDG

results. The temperature probe must be connected when creating Soil Models; use of the

temperature probe is optional when performing Field Testing. If the temperature probe is not used

during Field Testing, the EDG results cannot be temperature compensated.

EDG Battery/Battery Charger:

The EDG battery is rated at a capacity of 13.2 Amp-Hours. This is enough energy for continuous

operation for over 10 hours. The Battery Charger that is provided with EDG will charge the battery in

approximately 20 hours. Therefore, EDG should be placed on charge each day after use, and be

allowed to charge overnight. Remember, do not plug the charging cable into the socket on the soil

sensor, and make sure the charging voltage is DC 5V.

Note: Keep the cable connector out of the dirt to avoid getting dirt into the connector pinholes. A

paperclip can be used to clean out the pinholes if necessary.

V. The EDG Process in Depth

Soil Models, Soil Tests (a Soil Test is a single Test Spot in a Soil Model), Job Sites, and Field Tests (a

Field Test is a single Test Spot in a Job Site) are identified in the EDG process by a simple numbering

-4 -

system. The EDG automatically assigns numbers to newly-created Soil Models, Soil Tests, Job Sites,

and Field Tests.

Also, the user can assign names to Soil Models and Job Sites to help keep track of data. The operator

is required to manually keep track of the location that is associated with a particular Soil Test or Field

Test. A log or map might prove useful in keeping track of this data.

Note that these assigned names do not have to be unique, so the operator needs to avoid later

confusion. If a Soil Model or Soil Test is deleted, the Soil Model number or Soil Test number is not re-

used by the EDG.

Similarly, if a Job Site or Field Test is deleted, the Job Site number or Field Test number is not re-used

by the EDG.

For an untested type of soil, a Soil Model is created first. To create a Soil Model, EDG electrical testing

is performed at several (more than three) chosen Test Spots. For each Test Sport, the physical wet

density, dry density, and percent moisture is obtained by laboratory test.

Readings of two soil connection configurations are taken at a single Test Spot, the electrical results

of which are averaged and automatically stored to provide a unique electrical signature for that Test

Spat. Next, Sand Cone and Moisture laboratory tests are run on soil from the center of the Test Spot.

After the EDG soil darts are removed. This physical data obtained from the Sand Cone test will be

entered into the EDG and combined with the electrical data that was stored in the EDG when the

EDG testing was done on the Test Spot. In addition to the Sand Cone test, if compaction results are

desired from the EDG, a Proctor Mold test is required to determine the point of optimum moisture

content and maximum compaction. EDG will store Proctor Mold test data so that percent compaction

information can be computed.

When electrical and physical data for three or more Test Spots (Soil Tests) on the same soil type have

been accumulated, this Soil Mode must be associated with the particular project where the data was

gathered by pressing "Not associated" in the Project List menu. The Soil Model List will show all the

soil models.

The Soil Model data is kept in the EDG until deleted, so that it can be associated with other projects

as required. After a project has its Soil Model Completed and Associated, the EDG can be used to

test any other project that is constructed with this same soil type.

-5 -

EDG tests are performed by first selecting the project menu, then testing with EDG. The EDG test is

performed by (first) driving four Soil Darts into the Test Spot at four quadrant points of a twelve inch

(12") circle. A Template is provided to ensure accurate positioning of the Soil Darts. The Soil Sensor

is then set up on the Template to make it easy to connect the Sensor fins to the Darts in the required

sequences.

Two configurations are tested to assure that a good electrical signature of the soil is obtained. They

are labeled A↔A and B↔B. The EDG programming will guide the operator through each different

configuration.

Simply, the A↔A connection might be a North-South connection of the Sensor Pins to the nearest

Darts. When switching wires, it is important that two wires connecting the Soil Darts are not allowed

to be crossed (the space between the wires never be allowed to be less than 1 inch), otherwise there

may be some small errors introduced in the measurement. The other B-B test would be an East-West

configuration. When the test (or more specifically, Field Test) is completed, the EDG will immediately

display the measured Wet Density, Dry Density, Moisture Content, and Percent Compaction

(associating Soil Model in advance). This data is stored for later viewing from the EDG or from Data

Sharing mode using a PC and a Windows TM EDG software application.

The Data Sharing mode of the EDG interacts with the EDG software running on a PC and allows the

operator to share project and Soil Model data with the PC application.

VI. Making a Soil Model

A Soil Model must be created so that the soil electrical signature can be correctly related to the

physical characteristics of that soil type. It is important that the Soil Model be created with the same

soil type at Test Spots of differing moisture content and dry density. EDG Results suffer considerably

when the moisture contents are limited to either a high or a low range only. Probably the best soil

model will result when samples of soil with moistures at 5.0%, 7.5%, and 10.0% are used as Test

Spots.

The ideal Test Spots for Soil Model samples will probably look like this:

98% compaction with 5% moisture

98% compaction with 7.5% moisture

-6 -

98% compaction with 10% moisture

92% compaction with 5% moisture

92% compaction with 7.5% moisture

92% compaction with 10% moisture

A minimum of three (3) Test Spots (or more specifically, Soil Tests) are required for a valid Soil Model.

VII. To create a Soil Model

1. Screw on the connector for the Soil Sensor Unit to the left side panel receptacle. Be sure that the

connector is tight so as to prevent the entry of dirt or moisture.

2. Screw on the Temperature Probe connector to the receptacle on soil sensor.

3. Press the round button on the left side of the EDG unit:

4、From the EDG Main menu, enter Model List menu by pressing Soil Models.

-7 -

5、Create a new Soil Model by pressing New Model.

Press bring up the keyboard, then input a name for the new model.

-8 -

6. Press Config to save the name of the Soil Model and return to the Model List menu.

Setup has two status, press Setup, the button will switch to Delete. When it is Setup, you can enter

Model Settings menu by pressing a model name. On the contrary, when it is Delete, you can delete

a model by pressing a model name.

7. Model Settings:

8. Press New Point to acknowledge the New Soil Test as the first of (at least) three (3) Test Spots

that will make up the Soil Model.

-9 -

9. Lay the Dart Template on the Test Spot. Drive the four (4) Darts into the soil through the holes in

the Template until the Dart shoulder is just even with, or slightly lower than, the soil surface. Then

connect it to the Soil Sensor.

10.Place the Soil Sensor Unit in the center of the Template with the Probe Pins pointing up. Using

the Red Cable, connect a Probe Pin to the nearest Dart, and with the Black Cable, connect the other

Probe Pin to the Dart on the opposite side of the circle. Let the Cables loop upward when connecting,

and keep them separated from one another. We'll call this first configuration “A-A”.

11. When using the Temperature Probe, drive a large nail 2 in. deep into the soil near the Test Spot.

Insert the Temperature Probe, and press down the soil around the probe shaft. (Note: The

temperature probe must be used when creating a Soil Model.)

12.Keep your hands away from the Cables, Darts, or Soil Sensor Unit, otherwise you may cause

errors. Press the EDG button to start testing. Testing will take approximately five (5) seconds.

13.Test Connection " B-B " will be performed with the Soil Darts that have not yet been used. This

will generate a measurement pattern that is at right angle to the first test. Connect the cables to the

yet unused Darts, and press the EDG button. There are now four (4) electrical soil measurements (2

for the A-A configuration, and 2 for the B-B configuration) recorded in EDG memory that will be

averaged into one final electrical signature of that test spot. The completion of the series of tests is

announced.

14.It is necessary to make physical determinations of the Wet Density, Dry Density, and Moisture

-10 -

Content of the soil at the center of each Test Spot (Soil Test). A Sand Cone test must be performed

for each Test Spot. Soil from the rat hole is removed and lab tested. Wrap or properly enclose the soil

sample to prevent it from drying out before the moisture test can be run. Be sure that the Sand Cone

soil is from the center of the Dart pattern and that the rat hole is at least 15 cm deep. The physical

characteristics determined in the lab will later be entered into the EDG to provide the EDG with a

relationship between electrical data and physical data- Be sure to keep track of which soil sample

goes with which Soil Test.

15. Note:

If a bad connection exists at any of the Cable connecting points, a message will advise you of this

problem. The test will be terminated and that test's data (only) will be lost.

If the EDG determines that the electrical data may be questionable, it will report "Electrical data for

this test cannot be displayed." It is advisable at this point to throw away the data and do the test over.

16.When the Soil Model electrical test for that Test Spot is complete, pressing Save will return to the

Model Settings menu.

17.Pull the Soil Darts out of the ground and find another Test Spot of different dry density and 1 or

Moisture Content. Move the EDG test set-up and repeat the electrical tests on a new Test Spot.

18.Test a minimum of three (3) Test Spots (Soil Tests) for this Soil Model. Taking a greater number

of electrical tests on a wider variety of Test Spots will enhance the accuracy of EDG.

19.A Proctor mold test is also run on the soil type to determine maximum dry density and optimum

moisture content. These data are later entered into EDG to complete the Soil Model.

20.After the Sand Cone and Proctor mold lab tests are complete, the Maximum dry density, Optimum

Moisture, and Soil Class are entered into EDG by selecting the Sail Model menu.

-11 -

21."No data" means that physical data of the Soil Model has not been entered into the EDG. The

data requires to be input according to laboratory results. Select a test apot, then press Modify. You

can enter the lab-determined physical data for this Test Spot (Soil Test) in the Soil Model.

-12 -

When you have completed entering physical data, the screen will show “Normal” for that Soil Test.

22.After entering all data, review the Soil Tests for Soil Model screen to be sure that there are at

least three entries, and that they are all complete.

Once a Soil Model becomes valid {3 complete Soil Tests), a check is run to see how well the Soil

Model "fits" the standard statistical Soil Model. If the Soil Model doesn't fit the statistical model very

well, a warning message is generated. Also a "goodness" of fit number of between 0 and 1 is reported,

where 1 is ideal. Fit 1 indicates the “goodness” of lab-determined wet density and physical data, and

Fit 2 indicates the “goodness” of lab-determined Moisture content and physical data. It is ideal that

both Fit 1 and Fit 2 are 1, which also means the Soil Model for the moment is the most accurate and

the highest accuracy of measurement.

VIII. Associating a Soil Model With a project

Before Field Tests can be performed at a particular project, a Soil Model must be Associated with

the project. The following tells how to associate a Soil Model with a Job Site.

1、From the EDG Main menu, press Project Test.

-13 -

2. Press New Project:

After input a name to the project, press Confirm to save it.

- 14 -

3. Enter Model List menu by pressing Not associated.

Press a soil model name to associate with project1.

Note: the program will prevent an association of an incomplete Soil Model with a project. If correct

association failed, it means the physical data has not been entered into the Soil Model or there is

any other problem. Therefore, check over the Soil Model is required.

- 15 -

After successful association, the next step is conducting a Field Test. The Soil Model and a project

also can be associated after the Field Test, but the actual physical characteristics such as Wet

Density and Moisture content are unable to be determined on the site. It needs to input correct

physical characteristics of the Soil Model first and conduct association next before view the data

from Test Results menu.

IX. Project test & view the results

1. Select a project and press Start:

- 16 -

Test Method is the same as soil model test. After read B-B, the results will show on the screen:

2. After saved the test data, you can view the results by pressing a project name in the Project List

menu.

In this menu, you can delete test spots and generate a report for this project. The report is named

as xxx.csv, and you can open it with EXCEL.

- 17 -

3. After making a report, you can check it on computer by Type-C data cable.

Warning:

a) If the EGD unit cannot shut down after the data transmission, you should shut down it with

a magnet close to the "reset area for induction" which is on the back of EDG unit.

b) The TYPE_C cable only be used to transmit data.

X. Features Setup

1. Temperature Setting: to calibrate current temperature (EGD is equipped with data temperature

probe and calibration is unnecessary).

2. Backlight: adjust the brightness of the backlight.

3. Time Zone: convenient GPS automatic timing.

4. Date & Time: manual fix the time

5. Storage: view the storage footprint.

6. Calibration: calibration the sensor by calibration module. The module only used to calibrate the

soil sensor that it is inaccurate.

- 18 -

XI. Notice

1. EDG is a kind of instrument based on electromagnetic measurement. The measuring energy

present when using EDG is less than one tenth of that when you are using a cell phone. There is no

nuclear radiation and it is absolutely safe!

2. EDG itself cannot measure the density and moisture content directly and need to associate

physical data with electronic data by creating the Soil Model. Therefore, EDG accuracy is dependent

upon the accuracy of the calibration of the Soil Model, and the precision of the standard physical

tests.

3. When the measurement is conducting, a stable electromagnetic field is created between two soil

darts and the strength of electromagnetic field is directly related to the distance between darts,

which eventually effect the precision of measurement. Therefore, when driving the darts using

hammer, try to keep the positions of darts and the hole on the template fixed and guarantee the

darts are vertical to the ground to maximum extent.

XII. EDG Technical Specifications

EDG is packaged in a water-resistant enclosure and employs water resistant connectors, but it is not

intended for use during rain.

EDG will operate correctly to an altitude of 10,000 ft

Wet Density Range: As found in typical compacted earth sites, with Dry Density Accuracy: Typically

within 3% of standard physical tests

Moisture Content Range: As found in typical compacted earth sites, with Moisture Content Accuracy:

Typically within 3% of standard test

Internal Power: 3.7V lithium battery, 16800mAh capacity; Battery Time: about 24 hours

Ambient Temperature Range: a deg. C to 50 deg. C; Ambient Humidity Range: 5% to 90% non-

condensing

Memory Capacity:

Soil Models: Approx. 48

Table of contents

Other C-Tech Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

CHART

CHART Cyl-Tel quick start guide

MDT Technologies

MDT Technologies SCN-GLED1 01 Series Technical manual

MEDAP

MEDAP S FLOW operating instructions

NorthStar

NorthStar EXPLORER W310 Installation and operation manual

Tonghui

Tonghui TH2817 Operation manual

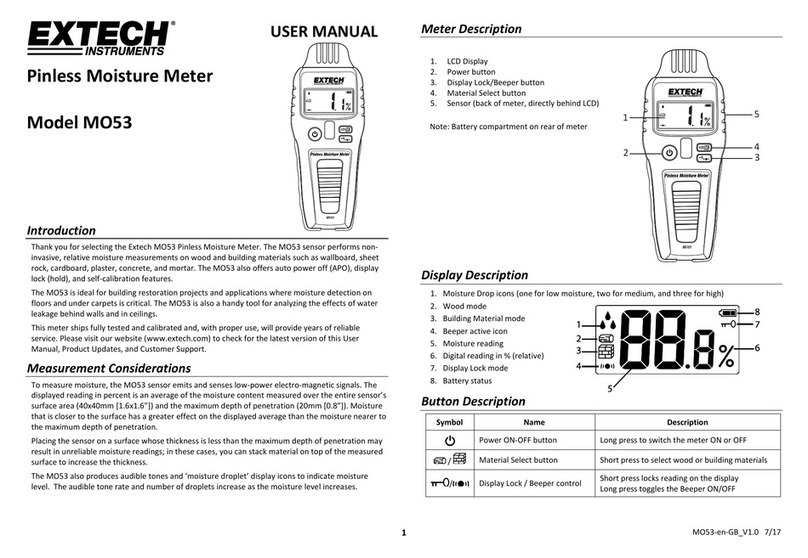

Extech Instruments

Extech Instruments MO53 user manual