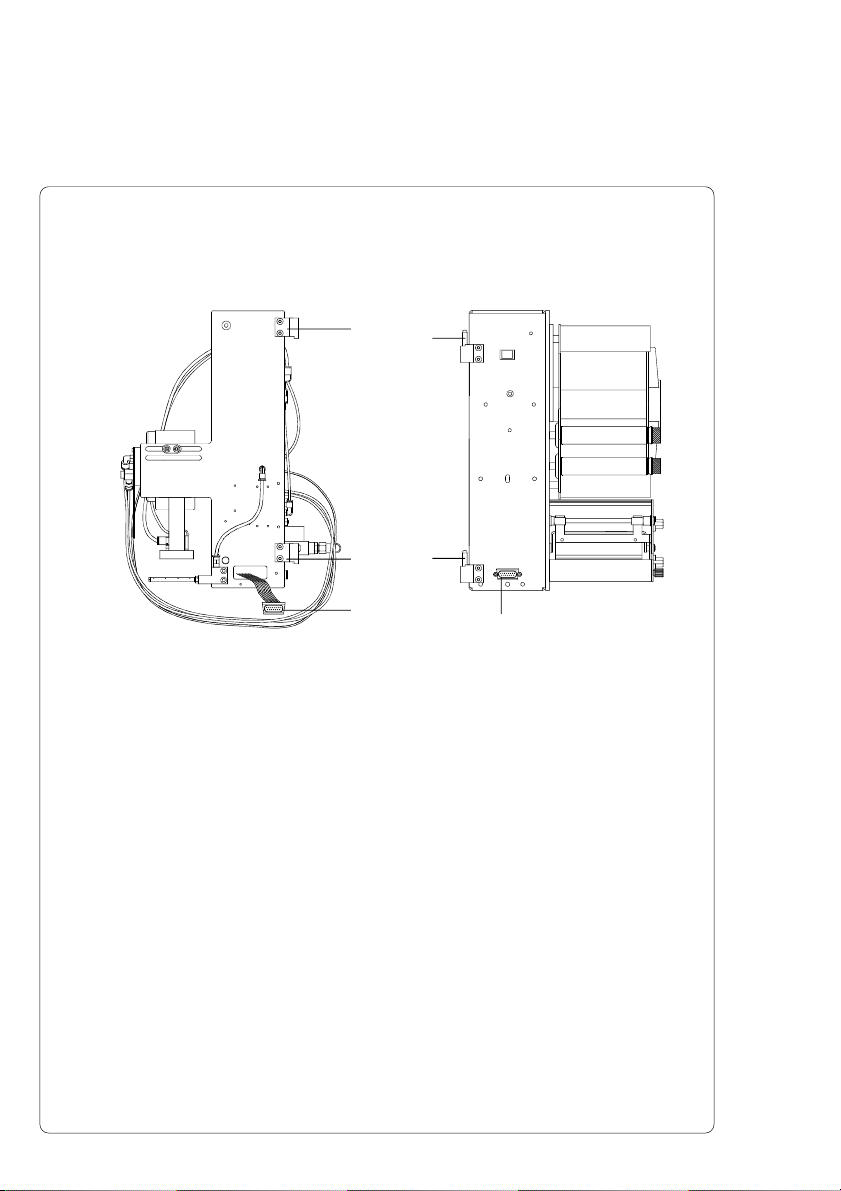

Blow Applicator with Swing Cylinder

cab - Produkttechnik GmbH & Co KG 3

Table of Contents

Copyright ......................................................................................................................... 2

Table of Contents ............................................................................................................ 3

1. Product Description ....................................................................4

Function .................................................................................................................. 4

Technical Data ........................................................................................................ 4

2. Equipment Supplied....................................................................5

3. Safety Instructions ...................................................................... 6

4. Installation ...................................................................................7

Installing the Blow Applicator on the Apollo ........................................................... 7

Installing the Blow Applicator on the Hermes ........................................................ 8

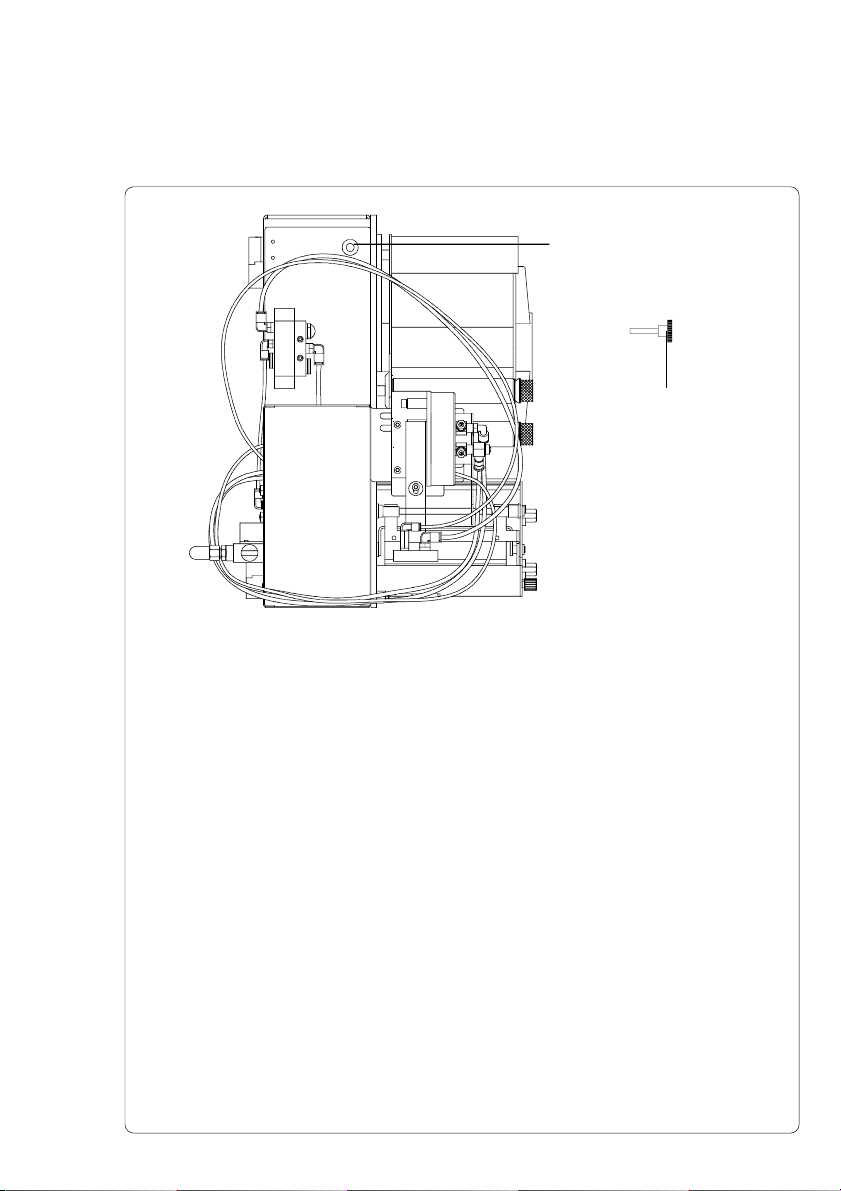

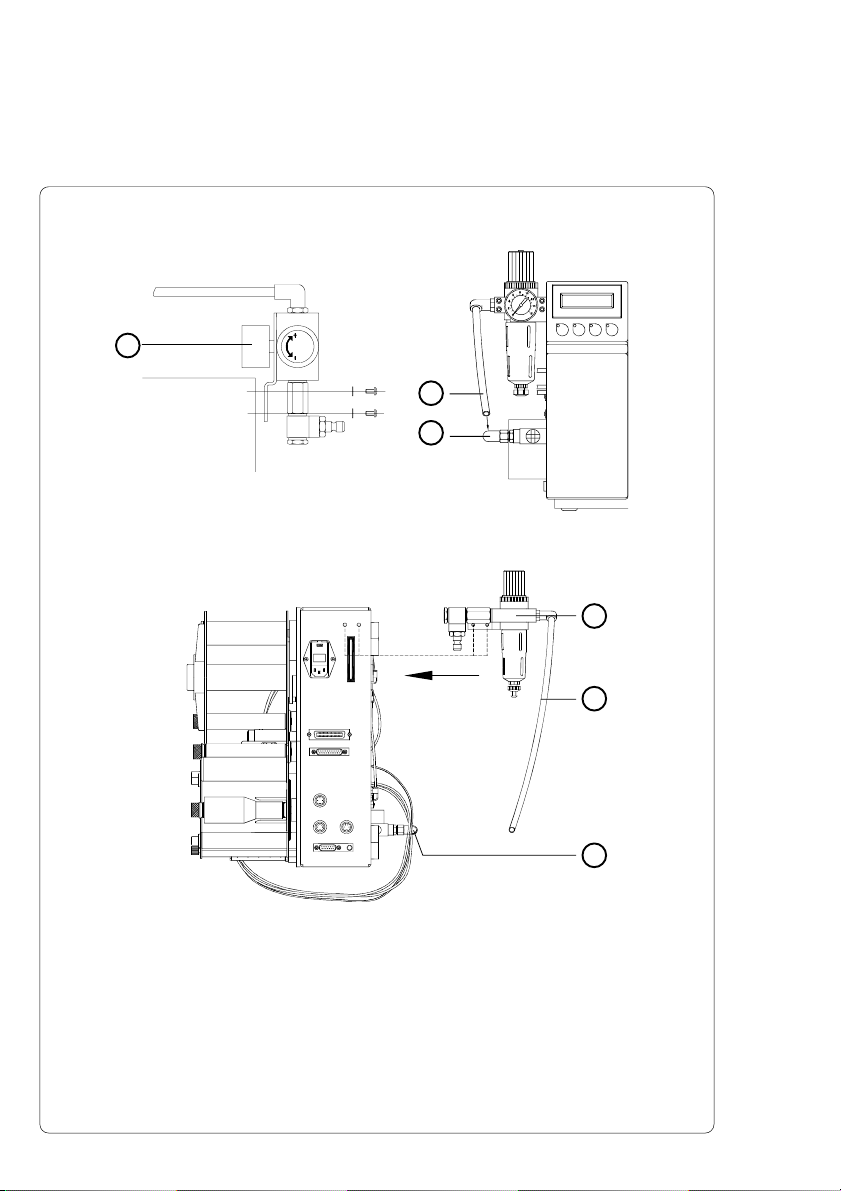

Installing the Service Unit .................................................................................... 10

Connections ......................................................................................................... 11

5. Adjustments ............................................................................... 12

5.1.Mechanical Adjustments ...................................................................................... 12

Angle of the Pad in the Starting Position ............................................................. 12

Adjusting the Level and the Sides of the Cylinder Unit on the Apollo ................. 13

Adjusting the Level and the Sides of the Cylinder Unit on the Hermes .............. 14

Tuning the Blow Tube .......................................................................................... 15

5.2.Pneumatic Adjustments ....................................................................................... 16

Control Valves ...................................................................................................... 16

Throttle Valves at the Cylinder ............................................................................. 17

Throttle Valves at the Manifold ............................................................................ 18

5.3.Selection of the Operation Mode ........................................................................ 19

Operation Mode 'Printing / Labelling' ................................................................... 19

Operation Mode 'Labelling / Printing - Waiting in the Starting Position' .............. 19

Operation Mode 'Labelling / Printing - Waiting in the Labelling Position' ............ 19

Function of the Pre-dispense Key ....................................................................... 20

Setting the Operation Mode and Delay Times..................................................... 22

Print Info Display .................................................................................................. 24

6. Operation .................................................................................. 25

Appendix A - PLC-Interface

Appendix B - Error Messages

Appendix C - Function of the LED of the Applicator Electronics

Index

EC-Conformity Declaration