7

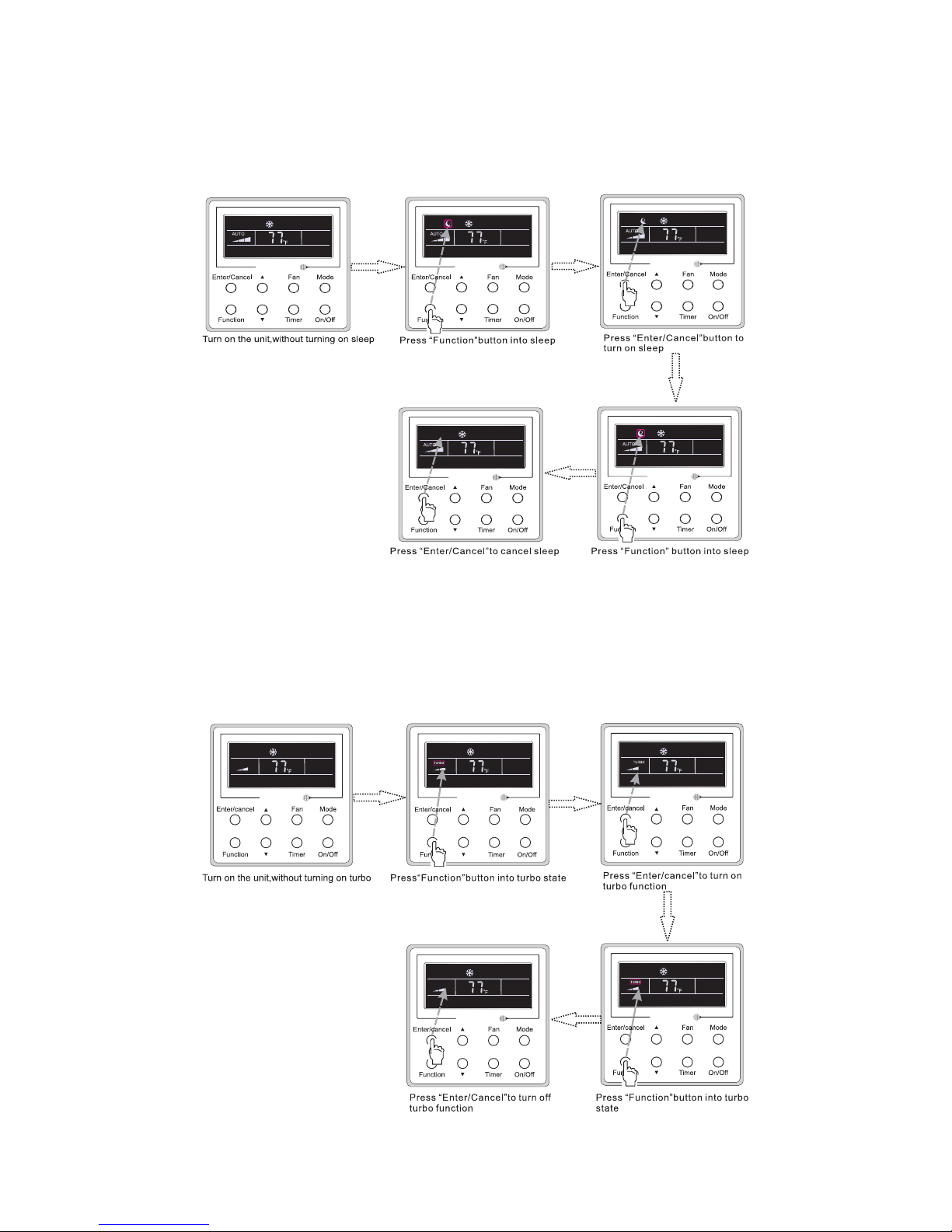

BLOW SETTING

SBLOW Function: After the unit turns off, the water in

the indoor unit’s evaporator automatically evaporates to

avoid mildew.

In the COOLING or DRY modes, press FUNCTION until the unit

enters the BLOW mode and then press ENTER/CANCEL to

activate the function.

When the BLOW function is activated, press FUNCTION, under

the BLOW mode interface, then press ENTER/CANCEL to

cancel the function (see Fig. 15).

Fig. 15 - Blow mode

NOTE: When BLOW is activated and the user turns off the unit by pressing ON/OFF or with the remote controller, the indoor fan will run

at low speed for 2 minutes, and “BLOW” appears on the LCD. If BLOW is deactivated, the indoor fan turns off. The BLOW

function is unavailable in the FAN or HEATING mode.

OTHER FUNCTIONS

1. LOCK: Upon start−up, without malfunction or under the

unit’s “OFF” state, press and at the same time for 5

seconds until the wired remote controller enters the LOCK

state and the LCD displays . Next, press and

together for 5 seconds to exit this function. Under the

LOCK function, all buttons are inactive.

2. Memory:

SMemory Switchover: Under the unit’s OFF state, press

MODE and at the same time for 5 seconds to switch the

memory states between MEMORY ON and MEMORY

OFF. When this function is activated, MEMORYappears.

If this function is not set, the unit remains under the OFF

state after a power failure and the subsequent power

recovery.

SMemory Recovery: If this function has been set for the

wired remote controller, the controller, after power failure,

resumesits original running state upon power recovery.

SMemory Contents: ON/OFF, MODE, set temperature

set fan speed and LOCK function.

3. Temperature Sensor Selection: Under the unit’s OFF

state,press both FUNCTION and TIMER for five seconds

to enter the commissioning status. Under this status, use

MODE to adjust the display in the temperature display area

to “00” and then adjust the temperature sensor option in the

timer display area with either or .

(1.) Indoor ambient temperature is sensed at the return

air inlet (01 in the timer display area).

(2.) Indoor ambient temperature is sensed at the wired

controller (02 in the timer display area).

(3.) Select the temperature sensor ar the return air inlet

under the COOLING, DRY, and FAN modes.

(4.) Select the temperature sensor at the wired controller

under the COOLING, DRY, and FAN modes and

select the temperature sensor at the return air inlet

under the HEATING and AUTO modes (04

displayed in the timer display area). The factory

default setting is #3.

After the setting, press ENTER/CANCEL to confirm and exit the

setting status.

NOTE: Users can use ON/OFF to exit the commissioning status

however the set data will not be kept.

NOTE: Under the commissioning status, if there is no operation

requested within 20 seconds after the last button was pressed, the

system reverts to the previous state without retaining the current data.