KSACN0201AAA

Owner's Manual

Wired Controller for

High Wall Ductless Systems

NOTE: Read the instruction manual before starting the installation.

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air−conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install,start−up, and service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning coils. All other operations should be performed by

trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

Follow all safety codes. Wear safety glasses and work gloves. Keep

quenching cloth and fire extinguisher nearby when brazing. Use

care in handling, rigging, and setting bulky equipment.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit. Consult

local building codes and National Electrical Code (NEC) for

specialrequirements. Recognize safety information.

This is the safety−alert symbol !

! . When you see this symbol on

the unit and in instructions or manuals, be alert to the potential for

personal injury. Understand these signal words: DANGER,

WARNING, and CAUTION. These words are used with the

safety−alert symbol. DANGER identifies the most serious hazards

which will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or death.

CAUTION is used to identify unsafe practices which may result in

minor personal injury or product and property damage. NOTE is

used to highlight suggestions which will result in enhanced

installation,reliability, or operation.

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position. There may be more than 1 disconnect switch.

Lock out and tag switch with a suitable warning label.

!WARNING

ELECTRICAL DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not install the wired controller in an area subjected

to excessive steam, oil or sulfide gas. Doing so may

cause the controller to to deform and/or fail.

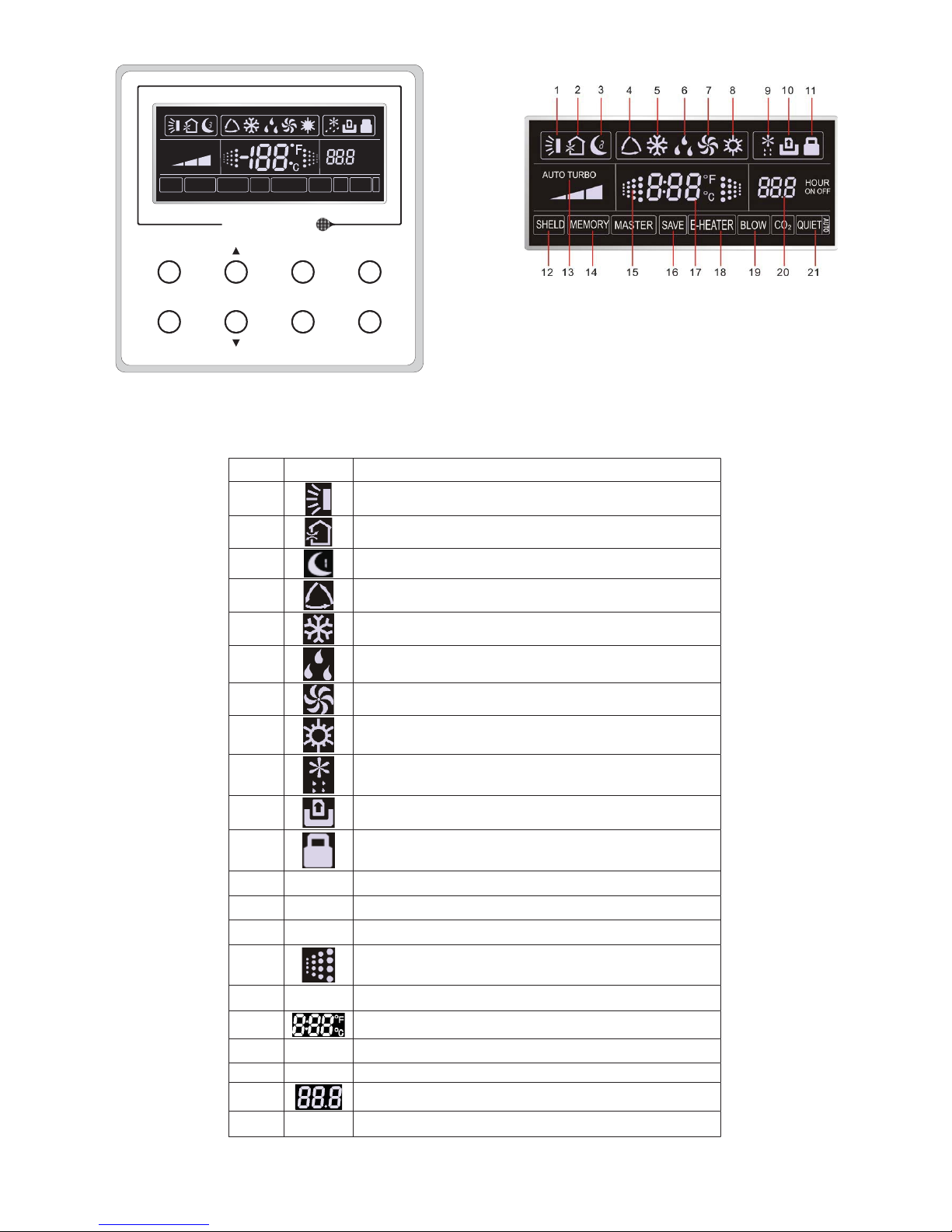

Enter/cancel

Enter/Cancel Fan Mode

Function Timer On/Off

SHIELD

MEMORY

MASTER

SAVE

BLOW

QUIET

CO

2

AUTO TURBO SET

HOUR

F

E-HEATER

A

U

T

O

Fig. 1 - Wired Controller

TABLE OF CONTENTS PAGE

SAFETY CONSIDERATIONS 1.........................

WIRED REMOTE CONTROLLER 2.....................

LCD DISPLAY ICON DESCRIPTIONS 2..................

WIRED REMOTE CONTROLLER BUTTONS 3............

OPERATION INSTRUCTIONS 4........................

INSTALLATION AND DISASSEMBLY 8.................