ROADSTER

PREDELIVERY

Bulletin

September 16, 2013 Subject:Can-Am™ Spyder™ RT Predelivery

Instructions

No. 2014-1

YEAR MODEL MODEL NUMBER SERIAL NUMBER

2014 Spyder RT Series Refer to table on next

pages for complete listing All

TABLE OF CONTENTS

Page Page

IMPORTANT NOTICE ....................... 2

UPDATE SUMMARY........................ 3

MODEL LISTING............................. 4

UNCRATING.................................. 5

Crate Cover Removal .......................... 5

Parts and Sub-crate Removal ................. 5

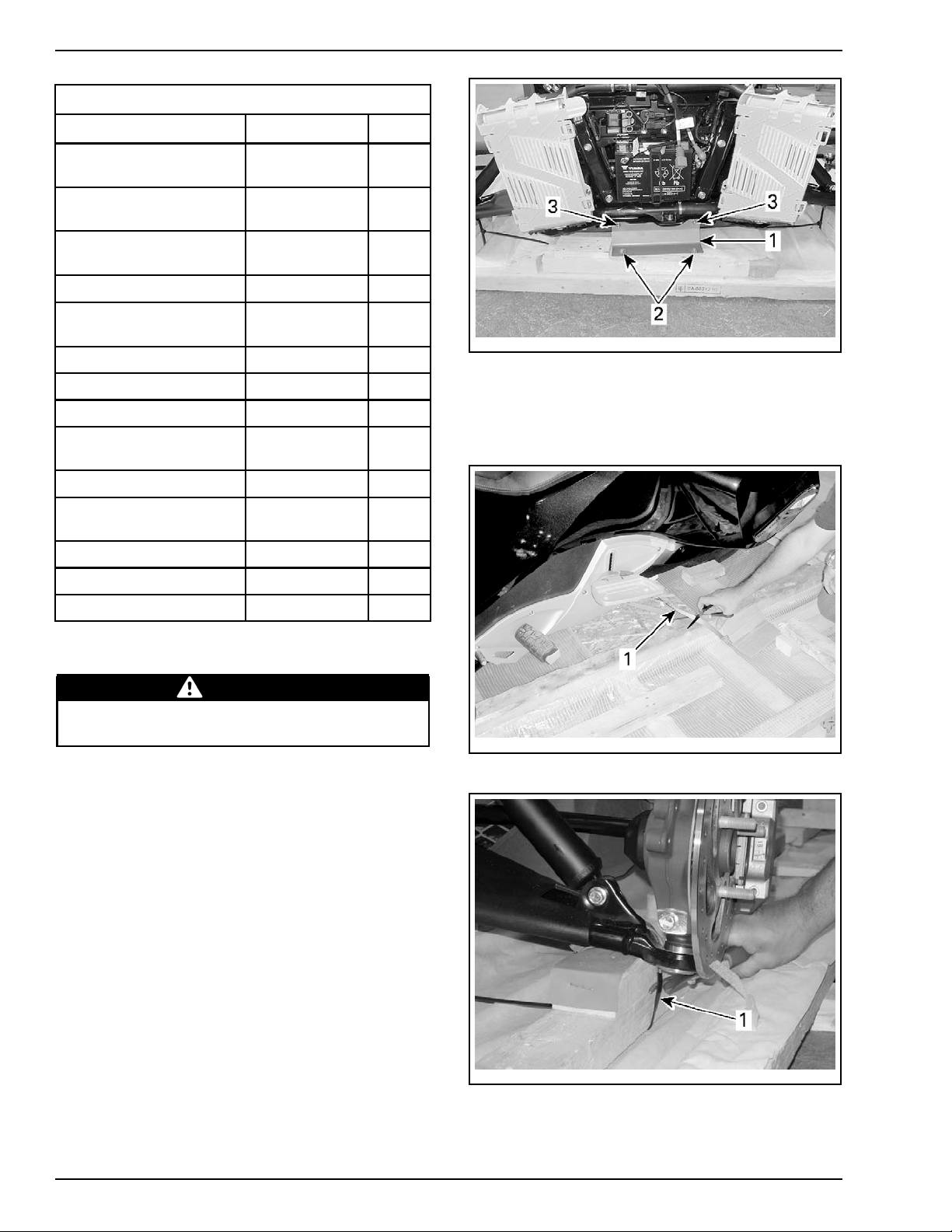

Parts Check...................................... 7

Lifting the Front of Vehicle ................... 8

Front Wheels Installation ...................... 9

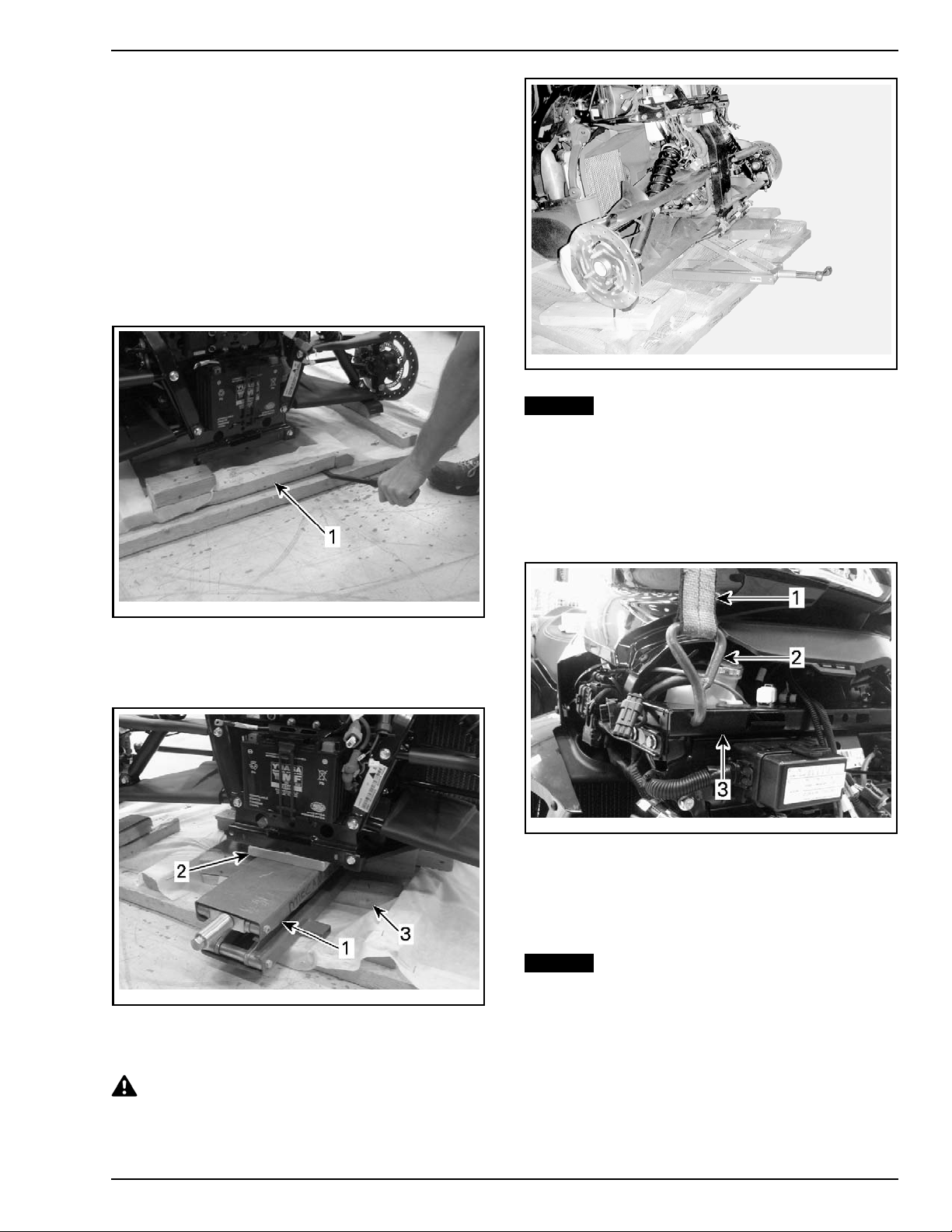

Vehicle Removal ................................ 11

PARTS TO BE INSTALLED................. 14

Front Cargo Module Installation .............. 14

Battery ........................................... 22

Body Parts Installation ......................... 24

Front Fenders ................................... 27

Windshield....................................... 28

Rear Turn Signal Lights Installation (Japan

Models Only) .................................... 29

Antenna.......................................... 33

Hang Tag and Safety Labels .................. 34

Licence Plate.................................... 34

Accessories Installation........................ 35

Vehicle Decals................................... 35

Key Barrel - Trailer RT 622..................... 36

FLUIDS......................................... 36

General Guidelines ............................. 36

Fuel............................................... 36

Engine Oil........................................ 36

Clutch Fluid (SM6 Model) ..................... 37

Engine Coolant.................................. 38

Brake Fluid....................................... 39

SETUP ......................................... 40

Guidelines ....................................... 40

Tire Pressure .................................... 40

Drive Belt ........................................ 40

Clutch Lever..................................... 42

Suspension ...................................... 42

Lights............................................. 43

Storage Compartment Covers................ 45

Clock and Language Setting .................. 47

B.U.D.S. Programming......................... 48

ASSEMBLY INSPECTION.................. 50

FINAL INSPECTION......................... 51

Vehicle Test Run................................ 51

Vehicle Cleaning ................................ 52

Delivery to Customer .......................... 52

Printed in Canada. (rbl2014-004 en JL)

©2013 Bombardier Recreational Products Inc. and BRP US Inc. All rights reserved. 1/52

®™ and the BRP logo are trademarks of Bombardier Recreational Products Inc. or its affiliates.