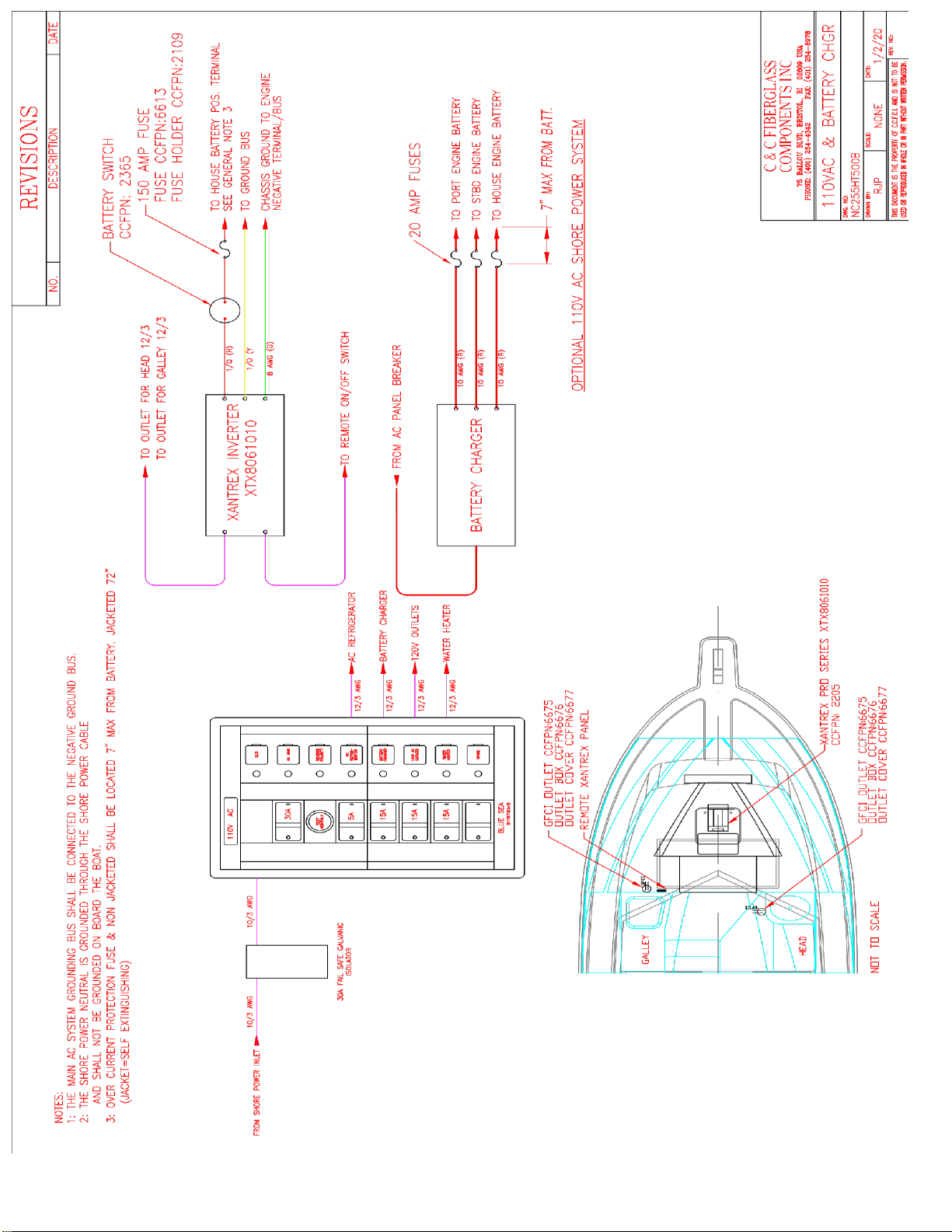

ELECTRICAL SYSTEMS

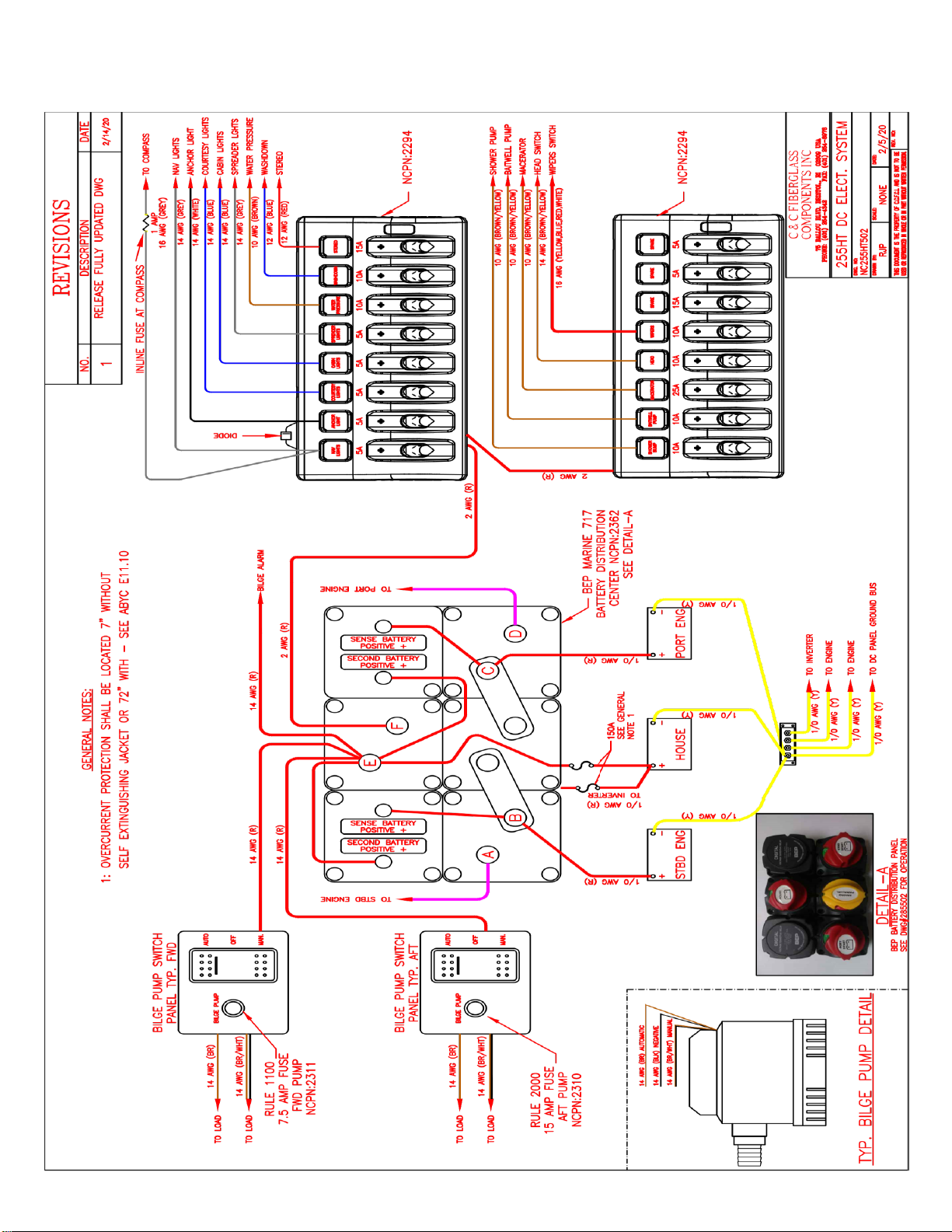

12 VOLT DC SYSTEM

•PANEL DESCRIPTION

The DC main electric panel distributes the ship's power from the house batteries and

protects each electrical component and associated ship's wiring from overcurrent

situations. One battery switch is used to select which battery will supply power to the

panel's main DC circuit breaker. The panel's main breaker protects the internal panel

wiring from potential dangers caused by operating more electrical components than the

panel can safely handle. It may be used like a switch to turn the entire system on and off.

Each electrical component is activated by a separate circuit breaker sized specifically for

that component and wiring. The panel includes a voltmeter to evaluate the quality of

power supplied by the battery.

•OPERATING PROCEDURES AND PRECAUTIONS

Prior to operating the electrical panel, use the "House" battery switch to supply the power.

Use the battery test switch to verify sufficient voltage to operate the system. Turn on the

panel main breaker and the individual breakers as desired. Before leaving the boat, turn off

the main breaker and the battery switch.

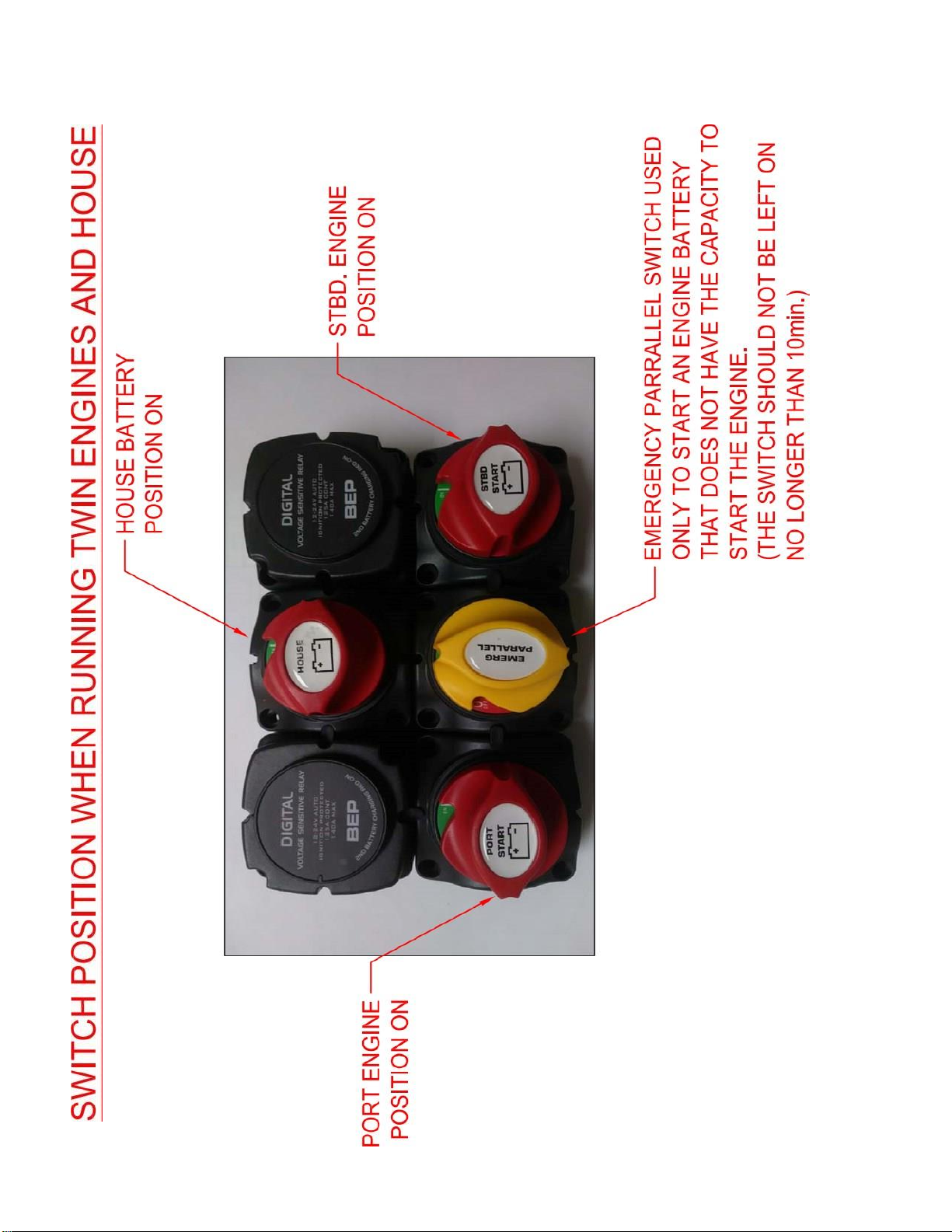

•BATTERY SWITCH

One rotary switch is mounted under by the helm station. These UL listed switches allow

power to go from the house batteries to the main DC panel. The engine batteries can be

supplemented temporarily with the house batteries by means of the paralleling switch at

the helm station. The engine batteries cannot be used in parallel with the house batteries to

power the main DC panel. The battery #1 battery #2 tester on the main DC panel is for

checking the status of the individual house battery banks. Industry convention uses battery

#1 as the "House" battery bank and battery #2 as the Engine battery bank. Battery bank #1

consists of two batteries wired in parallel to increase its capacity.

•BATTERY TEST SWITCH

The voltmeter installed on the electrical panel will give an indication of the charge status

of each of the house batteries. The voltmeter should read between 12.8V and 13.2V for a

fully charged battery. When the engine is charging the battery, the meter should read

between 14.2V and 14.8V.

•MINIMUM VOLTAGE REQUIREMENTS

As the power is used from the battery, the voltage supplied is reduced. To prevent damage

to electrical components, especially motors, do not operate the electrical system if less

than 11.0V is available.

•INDIVIDUAL CIRCUIT BREAKERS

Like the main breaker, the individual circuit breakers are designed to function as switches

as well as provide overcurrent protection. Space is provided for additional breakers if

optional electrical equipment is installed. We recommend that the individual breakers be

activated only as needed and left off otherwise.

•CABIN LIGHTS -- FORWARD

All of the cabin lights in the forward cabin are activated by this circuit breaker.