7

12 PIPING (continued)

Combustion air outdoor termination:

Use PVC elbow

7facing downward

and air intake screen provided

8. Maintain 12"

clearance above highest anticipated snow level.

Galvanized

IMPORTANT: For proper operation of the CAP System

galvanized pipe must be sealed air tight (including all

joints and seams) with hi-temp foil tape or mastic stress

tape.

When using galvanized, the CAP system connect-

ing flange 11 needs to be reversed (groove stripes/

wider opening on top). Galvanized should be fitted

inside wider opening until it hits stop/lip (may require

lubricant). Thinner end should be inserted into air inlet

opening 10 . There will be a smaller gap between edge

of connector and galvanized pipe. Tight seal is made

inside connector.

Termination hood (not provided) is needed for use with

galvanized pipe. Maintain 12" clearance above highest

anticipated snow level.

WARNING: Be sure to adhere to manufacturer’s

recommendations and all local codes with regards

to proximity of combustion air piping to appliance

vent/exhaust stack.

Avoid locations where snow may drift and block

combustion air. Ice or snow may cause boiler to

shut down if combustion air becomes obstructed.

Combustion air termination must be min. 12" from

or below doors, windows or gravity inlet. USE

SWEEP ELBOWS FOR ALL COMBUSTION AIR

PIPING. DO NOT USE short radius elbows for com-

bustion air piping – boiler performance could be

affected.

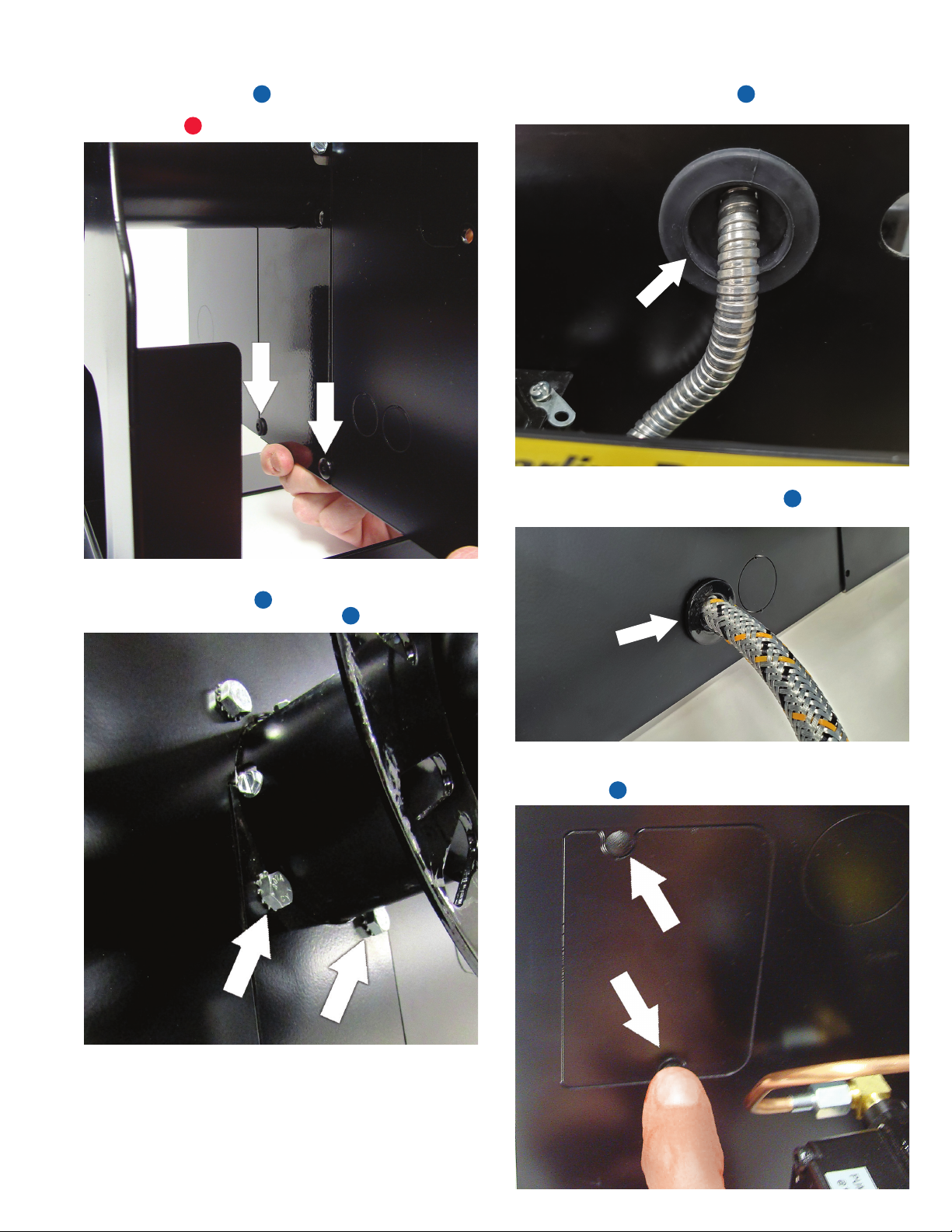

13 Mount the cover

1by aligning the two holes on the

top flange of the cover with the mounting tabs on the

backplate. Tighten the mounting screw 1b , located in

the center of the cover, securely to prevent basement air

from entering the cover.

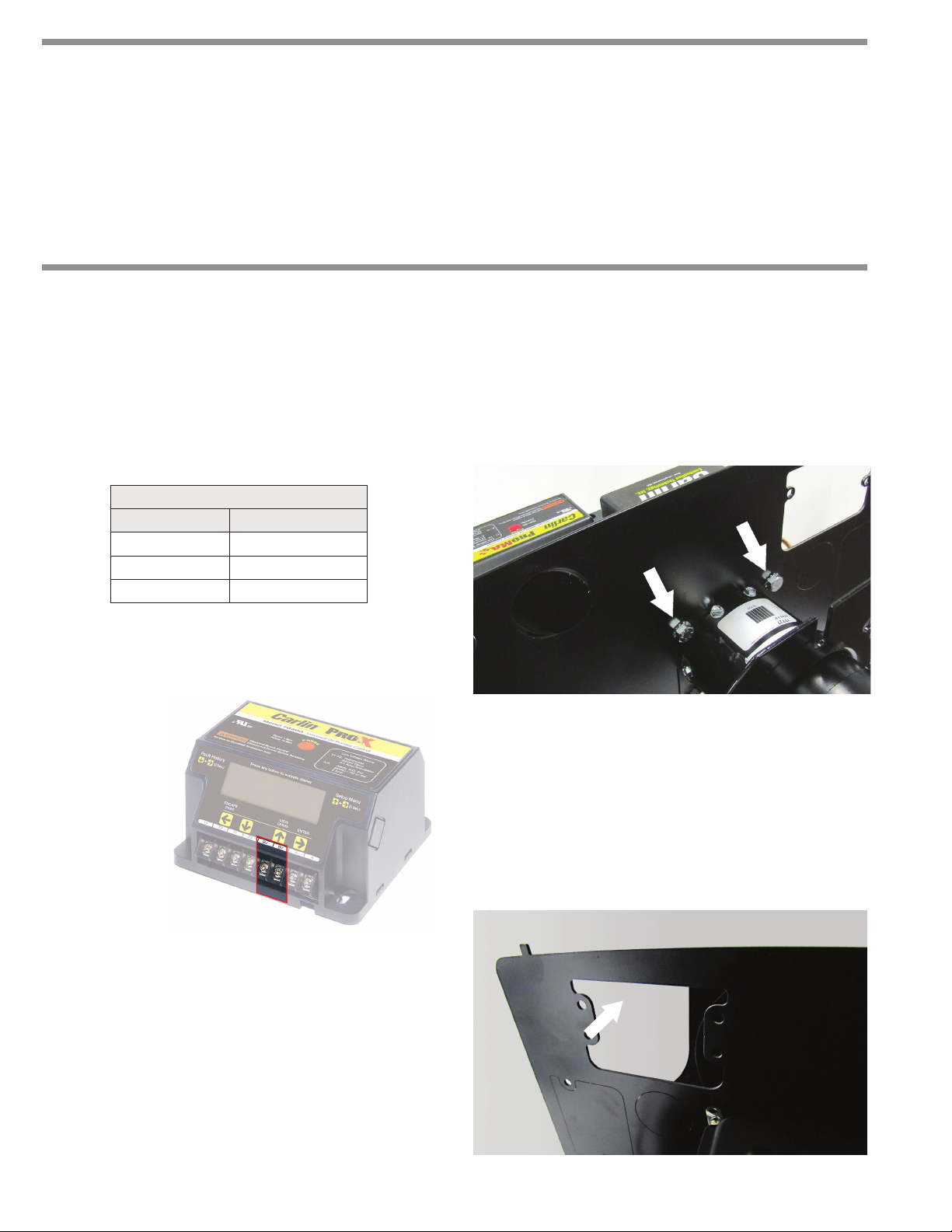

14 CHECK BURNER SETUP

CAP System utilizes outside air for combustion.

Incoming air temperature will fluctuate by season

which can significantly impact combustion. Use the

table below to set the combustion settings based on

outside temperatures at the time of setup.

• Apply the burner setup label 20

to the top of the burner cover

1.

10 Route the Air Flow Switch Wire Harness 10a from the

combustion air inlet 10 to the low voltage blocked vent

(BV) contacts on the Pro-X 70200 primary control.

11 SETTING BLOCKED VENT + AIR INTAKE FEATURE

The Pro-X 70200 Primary Control (manufactured

Sept. 2018 or later) is equipped with a Blocked Vent

Air Intake feature that works in conjuction with the CAP

System. To activate this setting:

• Press and simultaneously for 2 seconds. This

brings you to the settings menu.

• Scroll through the settings using until you reach

Vent Input.

• Scroll down to Intake using the .

• Press / ENTER button. The display will briefly indi-

cate Vent Input has been “Entered” and has replaced

any previous setting.

NOTE: If the Pro-X 70200 is also connected to a

blocked exhaust switch, call Carlin Technical Support

for assistance.

12 PIPING

3" PVC (recommended) or 4" galvanized vent pipe must

be installed to provide outside air to the CAP System.

(Maximum run of 80 total feet with each elbow equaling

10 feet. Example: 40 feet straight pipe and 4 elbows =

80 feet total run.)

Secure piping to connecting flange 11 using

clamp

6. (See step 9.)

NOTE: Galvanized pipe should not be used with firing

rate less than 0.65 GPH.

Important PVC Specs

For proper operation of the CAP System, air inlet piping

should only use schedule 40 or 80 PVC.

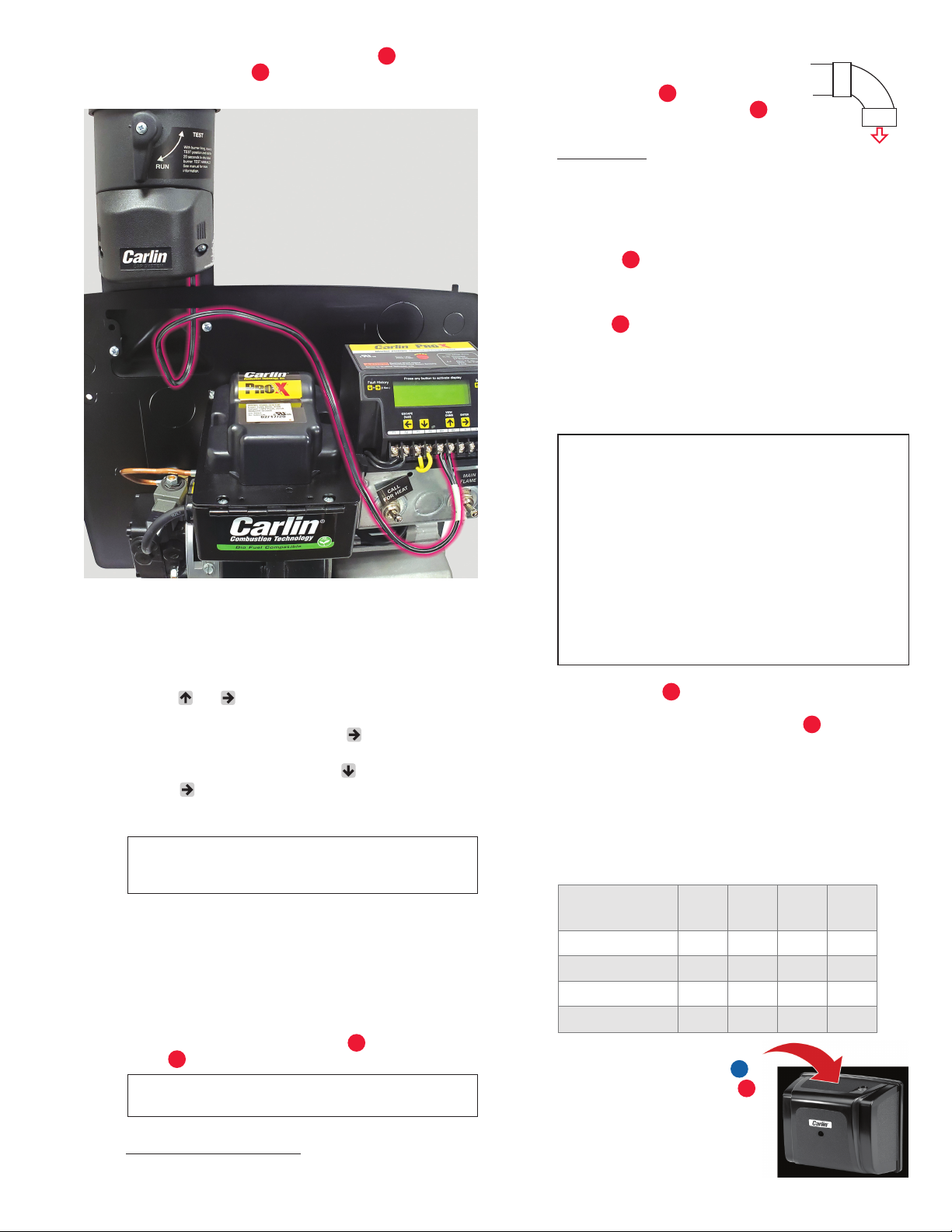

Incoming combustion

air temperature

during setup CO2min CO2max O2max O2min

–20°F to 0°F 10.2% 11.0% 7.0% 5.8%

5°F to 30°F 11.0% 11.5% 5.8% 5.5%

35°F to 60°F 11.5% 12.2% 5.5% 4.2%

65°F or higher 12.0% 12.5% 4.6% 3.9%