Installation, Start-Up and

Service Instructions

CONTENTS Page

SAFETY CONSIDERATIONS ...................1

INSTALLATION .............................1-11

Step 1 — Provide Unit Support ...............1

• ROOF CURB

• ALTERNATE UNIT SUPPORT

Step 2 — Rig and Place Unit ..................1

• POSITIONING

• ROOF MOUNT

Step 3 — Field Fabricate Ductwork ............8

Step 4 — Make Unit Duct Connections ........8

Step5—TrapCondensate Drain .............8

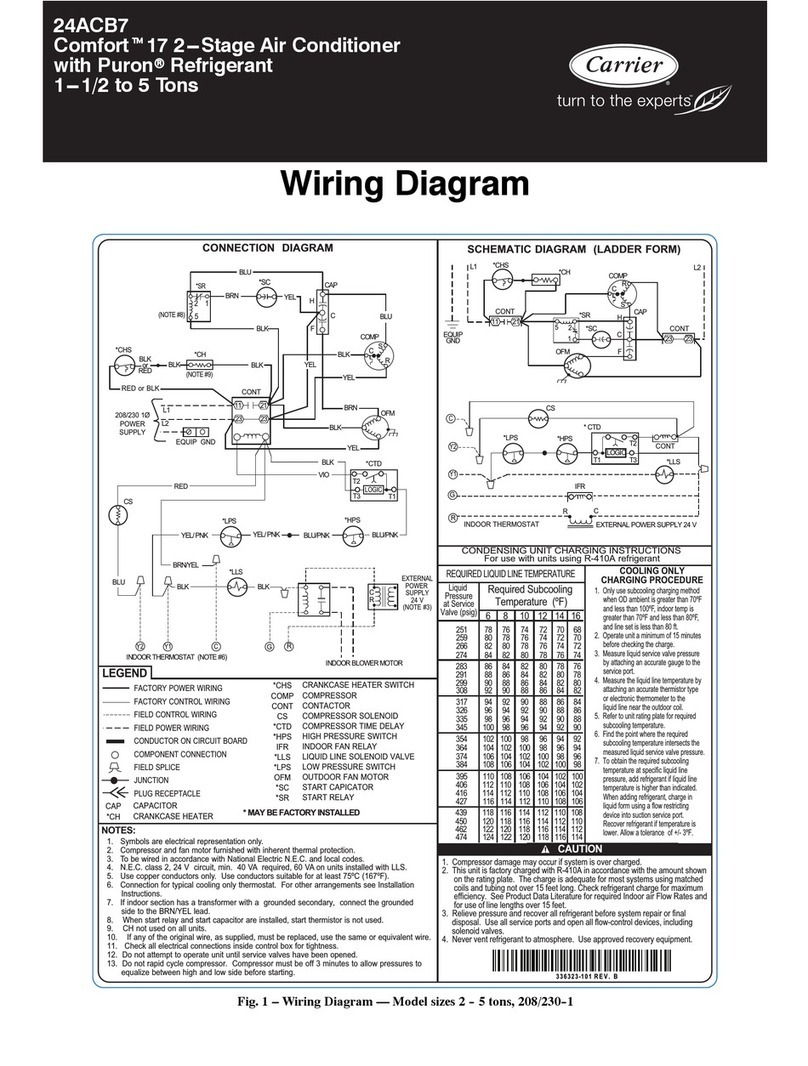

Step 6 — Make Electrical Connections ........8

• FIELD POWER SUPPLY

• FIELD CONTROL WIRING

Step 7 — Make Outdoor-Air Inlet

Adjustments ..............................10

• MANUAL OUTDOOR-AIR DAMPER

• OPTIONAL ECONOMIZER

Step 8 — Install Outdoor-Air Hood ...........11

START-UP .................................11-17

SERVICE ..................................18-22

START-UP CHECKLIST .....................CL-1

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment

can be hazardous due to system pressure and electrical com-

ponents. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance func-

tions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained service per-

sonnel. When working on air-conditioning equipment, ob-

serve precautions in the literature, tags and labels attached

to the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for unbrazing operations. Have fire ex-

tinguishers available for all brazing operations.

Before performing service or maintenance operations on

unit, turn off main power switch to unit. Electrical shock

could cause personal injury.

INSTALLATION

Step 1 — Provide Unit Support

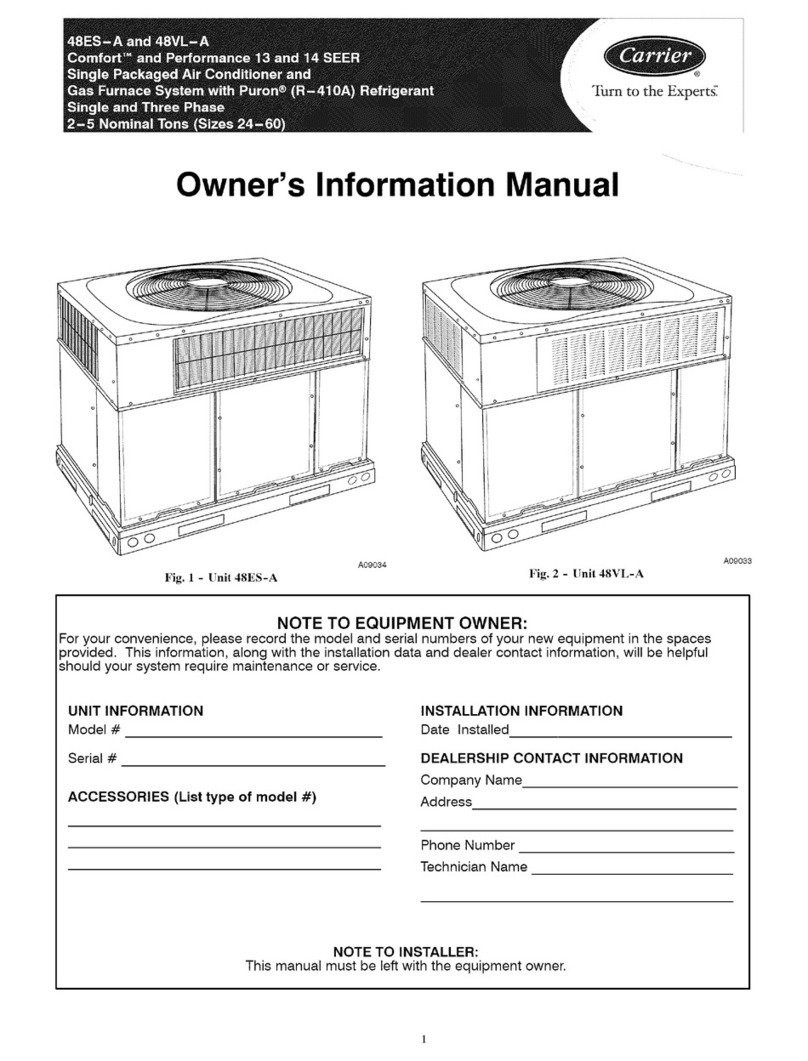

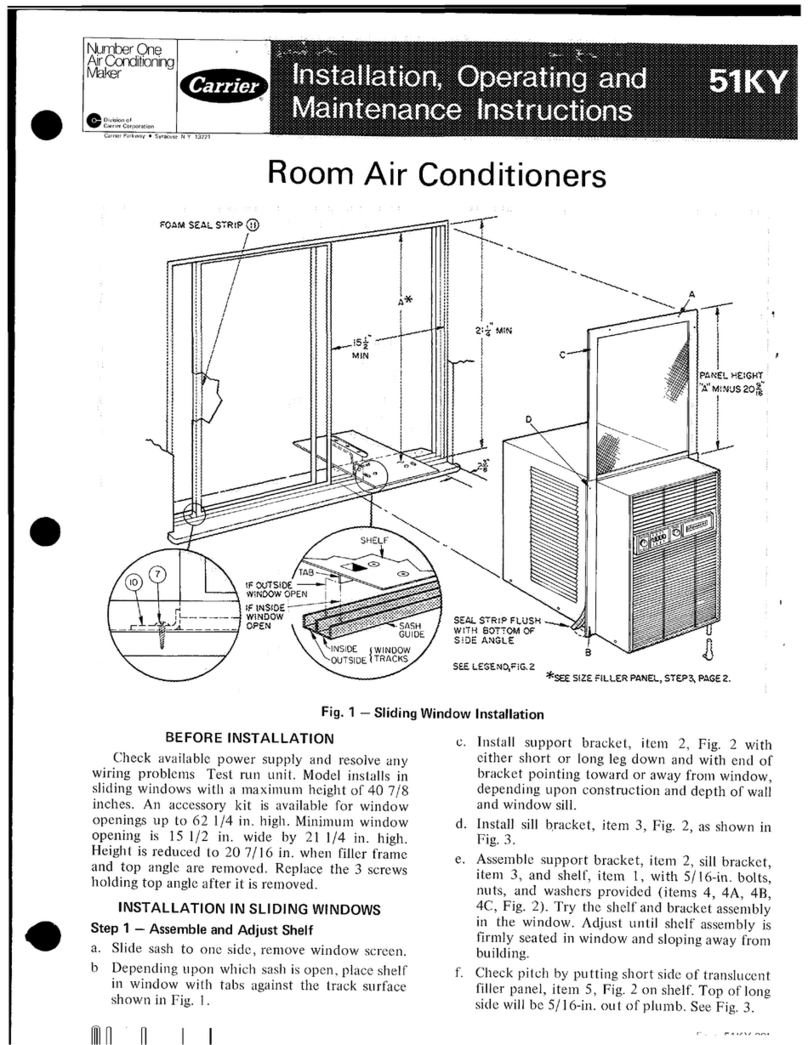

ROOF CURB — Assemble and install accessory roof curb

or horizontal adapter in accordance with instructions shipped

with the curb or adapter. Accessory roof curb and horizontal

adapter and information required to field fabricate a roof curb

or horizontal adapter are shown in Fig. 1. Install insulation,

cant strips, roofing felt, and counter flashing as shown. Duct-

work can be secured to roof curb or horizontal adapter be-

fore unit is set in place.

IMPORTANT: The gasketing of the unit to the roof

curb or horizontal adapter is critical for a watertight

seal. Install gasket supplied with the roof curb or hori-

zontal adapter as shown in Fig. 1. Improperly applied

gasket can result in air leaks and poor unit

performance.

Curb or adapter should be level. This is necessary to per-

mit unit drain to function properly. Unit leveling tolerance is

± 5 mm per linear m (±

1

⁄

16

in. per linear ft) in any direction.

Refer to Accessory Roof Curb or Horizontal Adapter Instal-

lation Instructions for additional information as required.

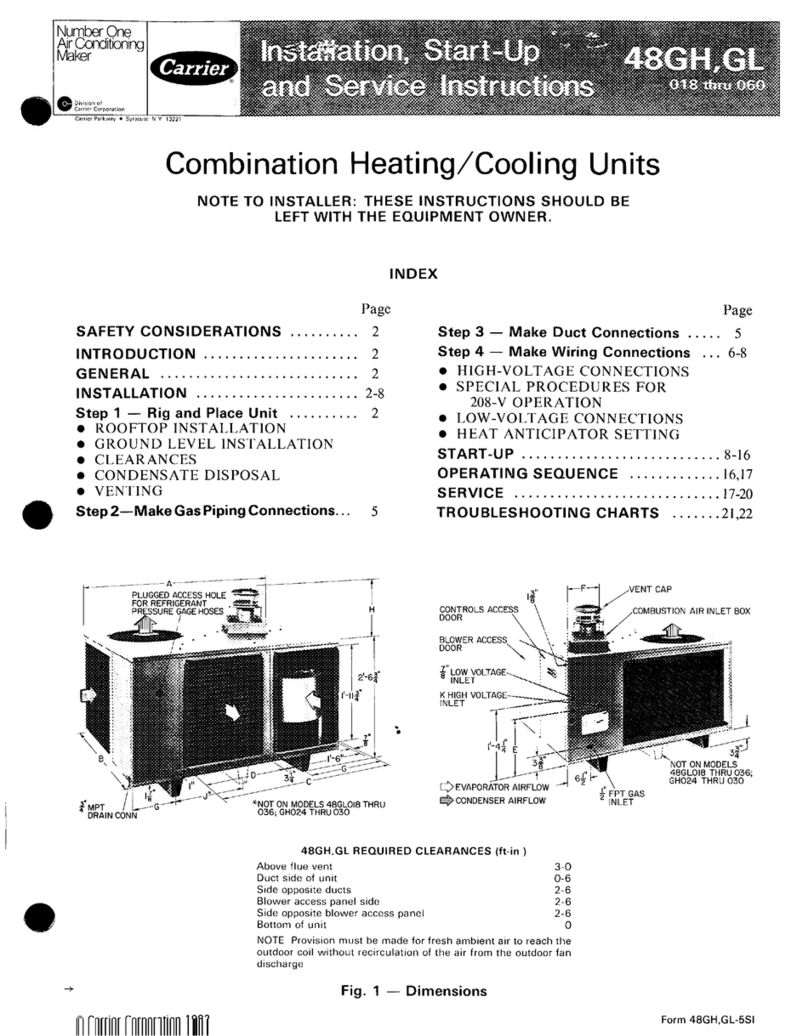

ALTERNATE UNIT SUPPORT — When the curb or adapter

cannot be used, support unit with sleepers using unit curb or

adapter support area. If sleepers cannot be used, support long

sides of unit with a minimum of 3 equally-spaced 100 mm

× 100 mm (4 in. × 4 in.) pads on each side.

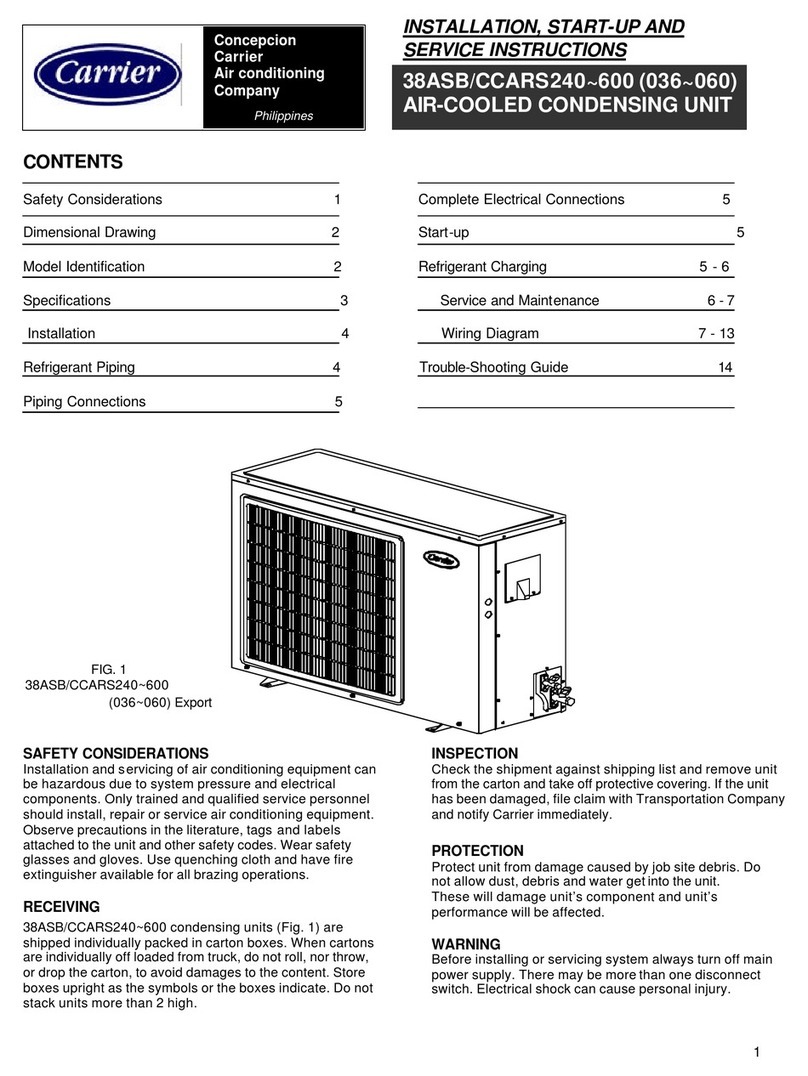

Step2 — Rigand Place Unit— Inspect unit for trans-

portation damage. File any claim with transportation agency.

Keep unit upright, and do not drop. Use bumper boards for

spreader bars over unit to prevent sling or cable damage.

Rollers may be used to move unit across a roof. Level by

using unit frame as a reference; leveling tolerance is±5mm

per linear m (±

1

⁄

16

in. per linear ft) in any direction. See

Fig. 2 for additional information. Unit weight is shown in

Tables 1A and 1B.

Four lifting holes are provided in ends of unit base rails

as shown in Fig. 2-4. Refer to rigging instructions on unit.

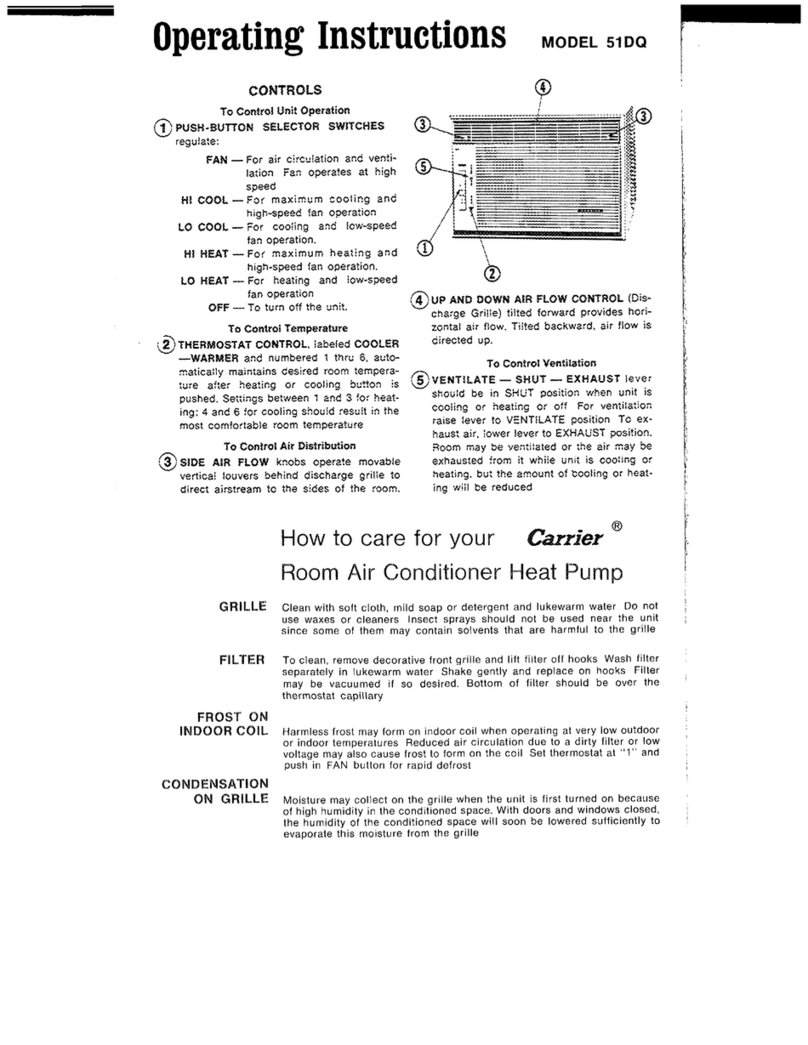

POSITIONING — Provide clearance around and above unit

for airflow, safety, and service access (Fig. 3 and 4).

Do not install unit in an indoor location. Do not locate air

inlets near exhaust vents or other sources of contaminated

air.

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

ROOF MOUNT — Check building codes for weight distri-

bution requirements.

50TJ016-028

Single-Package Rooftop Units

50 Hz

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1

Tab 1b Catalog No. 005-072 Printed in U.S.A. Form 50TJ-C8SI Pg 1 5-96 Replaces: 50TJ-C4SI