RAV-180-01SI Specifications subject to change without notice. 7

CURB-MOUNTED INSTALLATION

1. Install curb

2. Install field-fabricated ductwork inside curb

3. Install accessory thru-base service connection pack-

age (affects curb and unit) (refer to accessory instal-

lation instructions for details)

4. Prepare bottom condensate drain connection to suit

planned condensate line routing (see Install External

Condensate Trap and Line on page 11 for details)

5. Rig and place unit

6. Install outdoor air hood

7. Install condensate line trap and piping

8. Make electrical connections

9. Install other accessories

PAD-MOUNTED INSTALLATION

1. Prepare pad and unit supports

2. Check and tighten the bottom condensate drain con-

nection plug

3. Rig and place unit

4. Convert unit to side duct connection arrangement

5. Install field-fabricated ductwork at unit duct openings

6. Install outdoor air hood

7. Install condensate line trap and piping

8. Make electrical connections

9. Install other accessories

FRAME-MOUNTED INSTALLATION

Frame-mounted applications generally follow the sequence

for a curb installation. Adapt as required to suit specific in-

stallation plan.

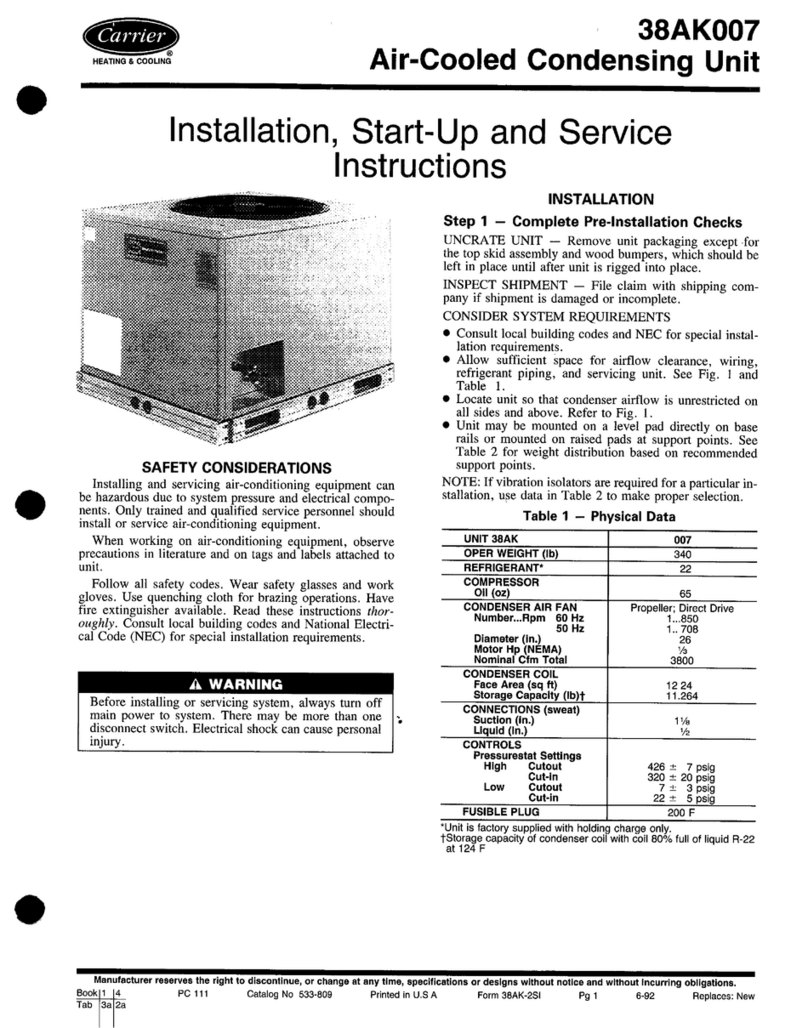

Step 3 — Inspect Unit

Inspect unit for transportation damage. File any claim with

transportation agency. Confirm before installation of unit that

voltage, amperage and circuit protection requirements listed

on unit data plate agree with power supply provided.

Step 4 — Provide Unit Support

ROOF CURB MOUNT

Accessory roof curb details and dimensions are shown in

Fig. 5. Assemble and install accessory roof curb in

accordance with instructions shipped with the curb. Curb

should be level. This is necessary for unit drain to func-

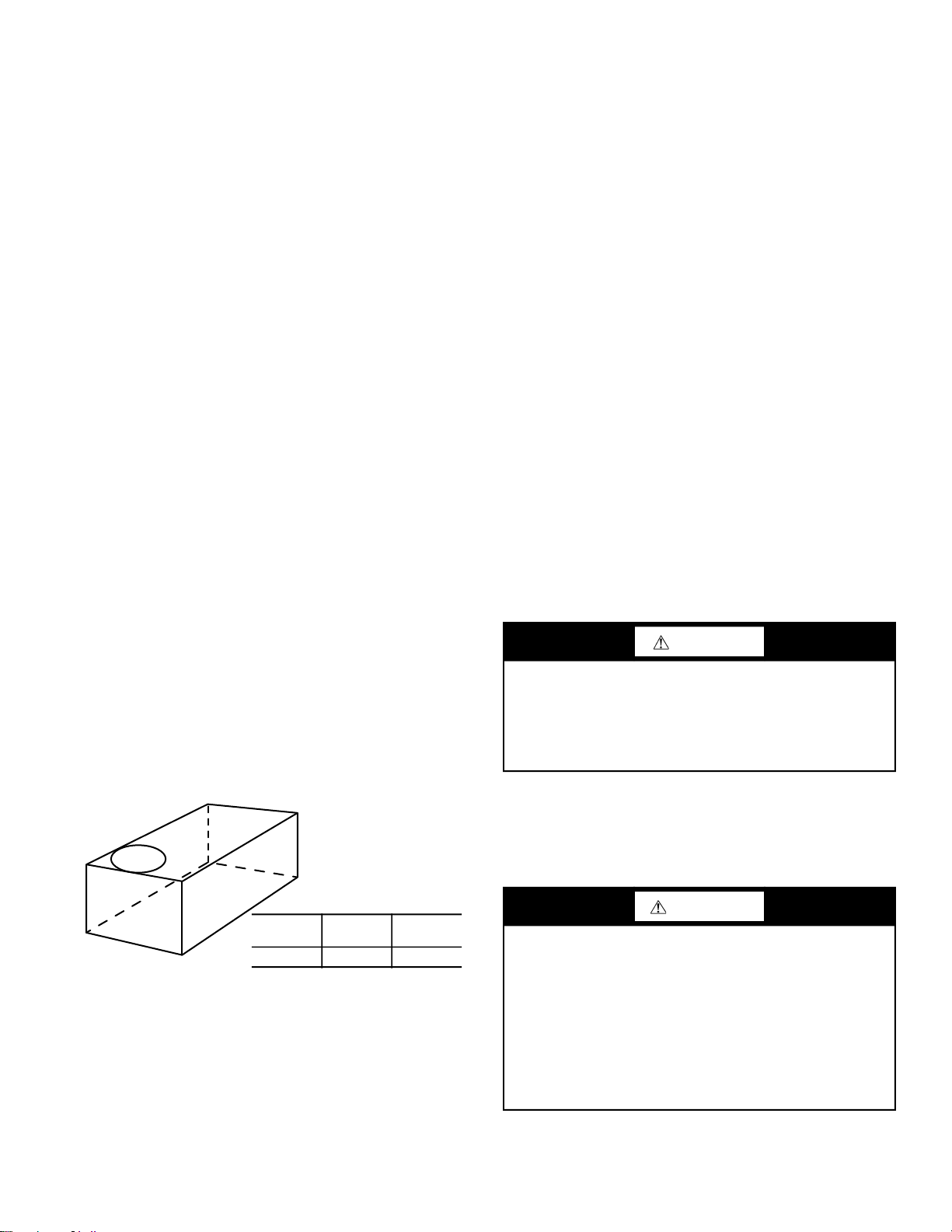

tion properly. Unit leveling tolerances are shown in Fig. 4.

Refer to Accessory Roof Curb Installation Instructions for

additional information as required.

Fig. 4 — Unit Leveling Tolerances

NOTE: The gasketing of the unit to the roof curb is critical

for a watertight seal. Install gasket supplied with the roof

curb as shown in Fig. 5. Improperly applied gasket can also

result in air leaks and poor unit performance.

Install insulation, cant strips, roofing felt, and counter flash-

ing as shown. Ductwork must be attached to curb and not to

the unit.

SLAB MOUNT (HORIZONTAL UNITS ONLY)

Provide a level concrete slab that extends a minimum of

6 in. (150 mm) beyond unit cabinet. Install a gravel apron in

front of condenser coil air inlet to prevent grass and foliage

from obstructing airflow.

NOTE: Horizontal units may be installed on a roof curb if

required.

ALTERNATE UNIT SUPPORT (IN LIEU OF CURB OR

SLAB MOUNT)

A non-combustible sleeper rail can be used in the unit curb

support area. If sleeper rails cannot be used, support the

long sides of the unit with a minimum of 3 equally spaced

4 in. x 4 in. (102 mm x 102 mm) pads on each side.

Step 5 — Field Fabricate Ductwork

NOTE: Cabinet return-air static pressure (a negative condi-

tion) shall not exceed 0.35 in. wg (87 Pa) with economizer

or 0.45 in. wg (112 Pa) without economizer.

For vertical ducted applications, secure all ducts to roof curb

and building structure. Do not connect ductwork to unit.

Fabricate supply ductwork so that the cross sectional di-

mensions are equal to or greater than the unit supply duct

opening dimensions for the first 18 in. (458 mm) of duct

length from the unit basepan.

Insulate and weatherproof all external ductwork, joints, and

roof openings with counter flashing and mastic in accor-

dance with applicable codes.

Ducts passing through unconditioned spaces must be insu-

lated and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return

should be ducted through the roof deck to comply with ap-

plicable fire codes.

A minimum clearance is not required around ductwork.

FOR UNITS WITH ACCESSORY ELECTRIC HEATERS

All installations require a minimum clearance to combustible

surfaces of 1 in. (25 mm) from duct for first 12 in. (305 mm)

away from unit.

Outlet grilles must not lie directly below unit discharge.

A-B

IN. (MM)

B-C

IN. (MM)

A-C

IN. (MM)

0.5 (13) 1.0 (25) 1.0 (25)

CAUTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in damage to

roofing materials.

Membrane roofs can be cut by sharp sheet metal edges.

Be careful when placing any sheet metal parts on such

roof.

WARNING

PERSONAL INJURY HAZARD

Failure to follow this warning could cause

personal injury.

For vertical supply and return units, tools or parts could

drop into ductwork and cause an injury. Install a

90 degree turn in the return ductwork between the unit

and the conditioned space. If a 90 degree elbow cannot

be installed, then a grille of sufficient strength and

density should be installed to prevent objects from falling

into the conditioned space. Due to electric heater, supply

duct will require 90 degree elbow.