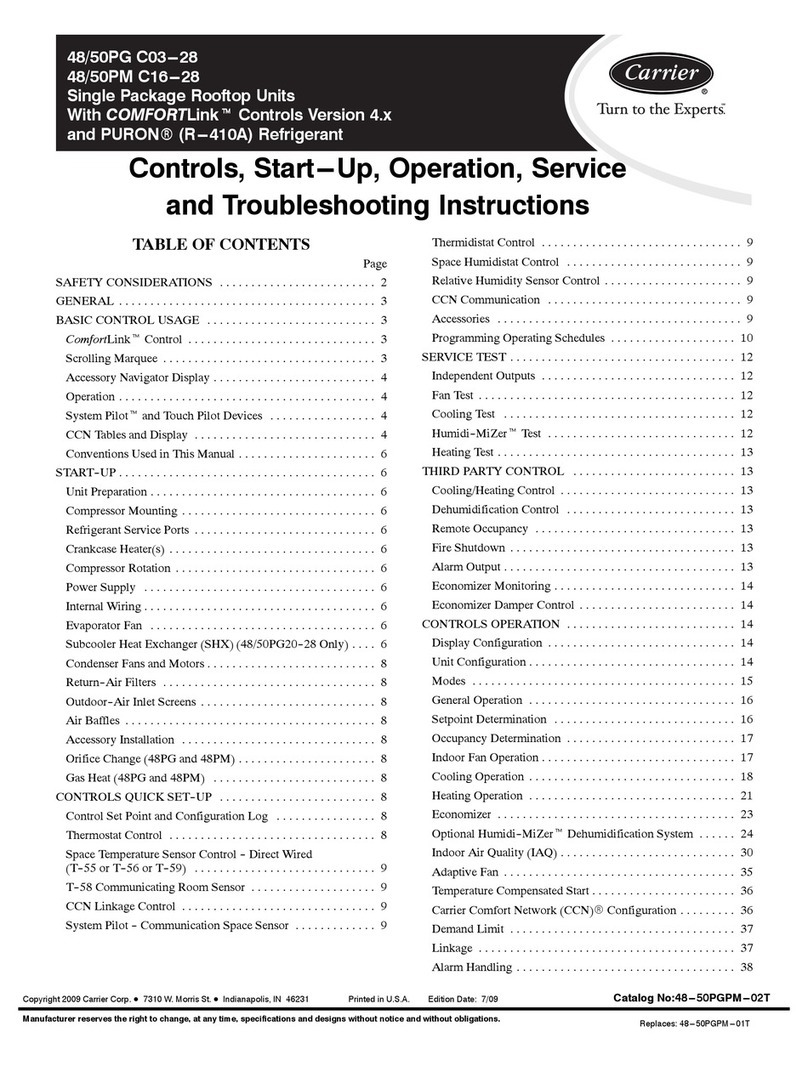

2

Actuators 40................................

Supply Air Temperature Sensor 40..............

Outside Air Temperature Sensor 40.............

Enthalpy Control Sensor Configuration 40........

Operating Sequences 41........................

Staged Air Volume (3--Speed) Fan Motor 41......

W7220 Economizer Control 41.................

Base Unit Controls 41........................

Cooling, Unit With EconoMi$er X Without CO241..

Heating With EconoMi$er X 43.................

Demand Control Ventilation 44.................

Setup and Configuration 44.....................

Initial Menu Display 44.......................

Time--out and Screensaver 44..................

Checkout 44.................................

Status 45...................................

Calibration of Sensors 45......................

Resetting All Defaults 45......................

Troubleshooting 45............................

Power Up Delay 45..........................

Power Loss (Outage or Brownout) 45............

Alarms 45..................................

Clearing Alarms 45..........................

Control Set Point and Configuration Log 48........

Staged Air Volume (SAVt)

with Variable Frequency Drive 50..................

Multi--Speed VFD Display Kit

(Field--Installed Accessory) 51...................

Connecting the Keypad to the VFD 52.............

Program the VFD for 3 Discrete Indoor Fan Speeds 53.

Smoke Detectors 61.............................

Step 13 -- Adjust Factory--Installed Options 62........

Step 14 -- Install Accessories 62...................

START UP CHECKLIST 63.......................

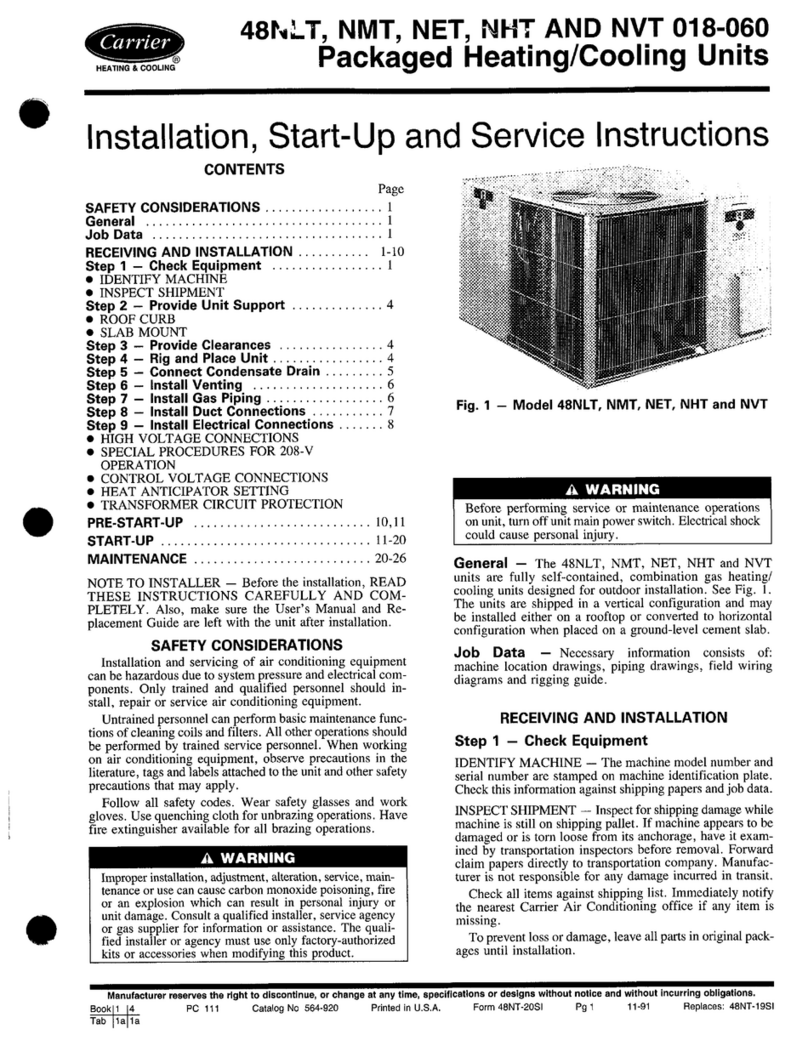

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock or other conditions which may cause personal injury

or property damage. Consult a qualified installer, service

agency, or your distributor or branch for information or

assistance. The qualified installer or agency must use

factory--authorized kits or accessories when modifying this

product. Refer to the individual instructions packaged with

the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloths for brazing operations and

have a fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions attached to

the unit. Consult local building codes and appropriate

national electrical codes (in USA, ANSI/NFPA70,

National Electrical Code (NEC); in Canada, CSA C22.1)

for special requirements.

It is important to recognize safety information. This is the

safety--alert symbol . When you see this symbol on the

unit and in instructions or manuals, be alert to the

potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety--alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or

death. WARNING signifies hazards which could result in

personal injury or death. CAUTION is used to identify

unsafe practices, which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced

installation, reliability, or operation.

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect gas piping from unit when leak testing at

pressure greater than 0.5 psig (3450 Pa). Pressures

greater than 0.5 psig (3450 Pa) will cause gas valve

damage resulting in hazardous condition. If gas valve

is subjected to pressure greater than 0.5 psig (3450

Pa), it must be replaced before use. When pressure

testing field--supplied gas piping at pressures of 0.5

psig (3450 Pa) or less, a unit connected to such piping

must be isolated by closing the manual gas valve.

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury or death.

Before performing service or maintenance operations

on unit, always turn off main power switch to unit and

install lock(s) and lockout tag(s). Unit may have more

than one power switch.

!WARNING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal

injury, death and/or equipment damage.

Puronr(R--410A) refrigerant systems operate at

higher pressures than standard R--22 systems. Do not

use R--22 service equipment or components on Puron

refrigerant equipment.

!WARNING

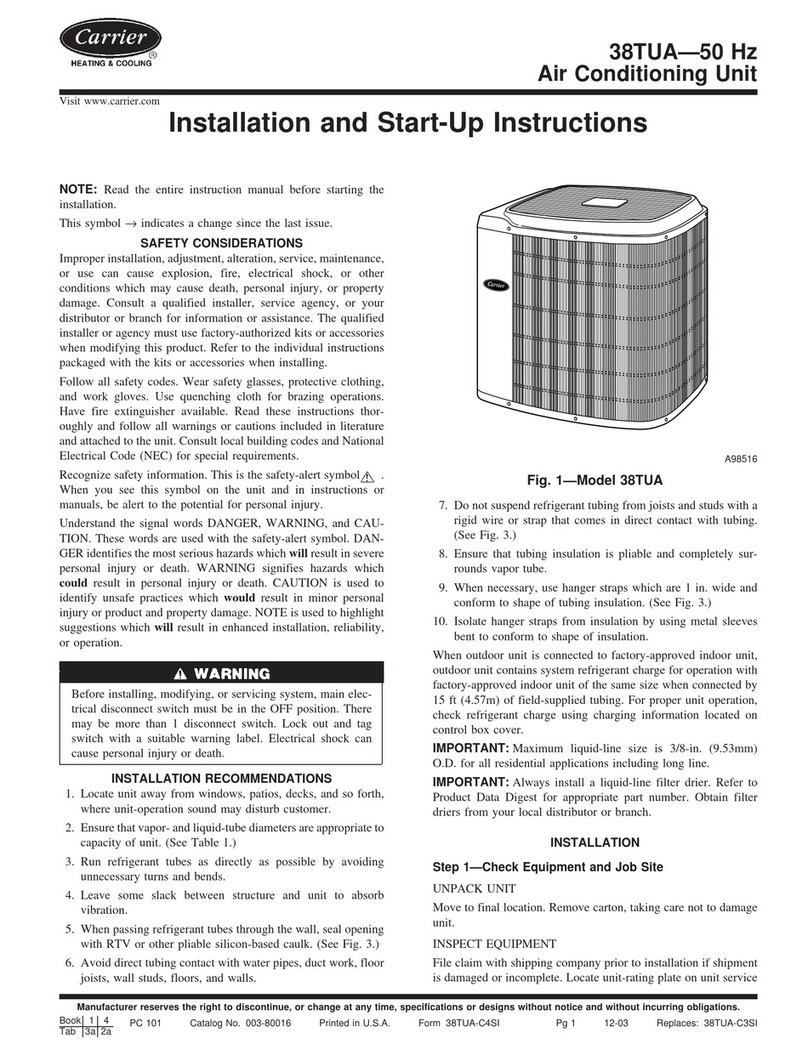

48HC48LC