2

50ZH

the amount of standing water inside the

unit, which limits mold and mildew

growth.

DURABLE STEEL CABINET —

The

watertight construction and corrosion-

resistant finish of the 50ZH unit will

keep it looking like new for years. A

specialized paint treatment process

ensures quality protection against the

elements. A compact, low-profile design

utilizes a louvered coil enclosure for

maximum protection against hail

damage and vandalism.

SCROLL COMPRESSORS —

Each

50ZH unit comes standard with a high

reliability design scroll compressor.

Each scroll compressor is hermetically

sealed against contamination to help

promote longer life and dependable

operation. All scroll compressors have

internal high-pressure and overcurrent

protection.

COIL EFFICIENCY —

Indoor and

outdoor coils are computer designed for

optimum heat transfer and cooling

efficiency.

CHRONOTEMP™ DEFROST

SYSTEM —

The system provides time/

temperature-based defrost cycles to

maintain unit efficiency. This highly

reliable system checks for coil icing

conditions at preset intervals and

initiates a defrost cycle only if it is

required. The defrost cycle ends as soon

as defrosting is accomplished. Each

defrost board is also equipped with 5-

minute compressor time delay

protection.

ACCESSORY ELECTRIC

HEATERS —

A variety of accessory

electric supplementary heaters are

available for the 50ZH units. Each heater

is a drop-in style cartridge type with

single-point electrical connections for

both the heater and the unit.

STARTER COLLARS —

Starter

collars are provided with each unit to

provide easy connection to the structure

ductwork.

DEPENDABLE COMPONENTS —

Direct-drive multispeed, PSC

(permanent split capacitor) blower motor

is standard on all models.

Direct-drive, PSC outdoor-fan motors are

designed to help reduce energy

consumption and provide for cooling

operation down to 40° F.

Refrigerant system is designed to

provide dependability. Liquid refrigerant

strainers are used to promote clean,

unrestricted operation. Each unit leaves

the factory with a full refrigerant charge

and is fully run tested. Refrigerant

service connections make checking

operating pressure easier.

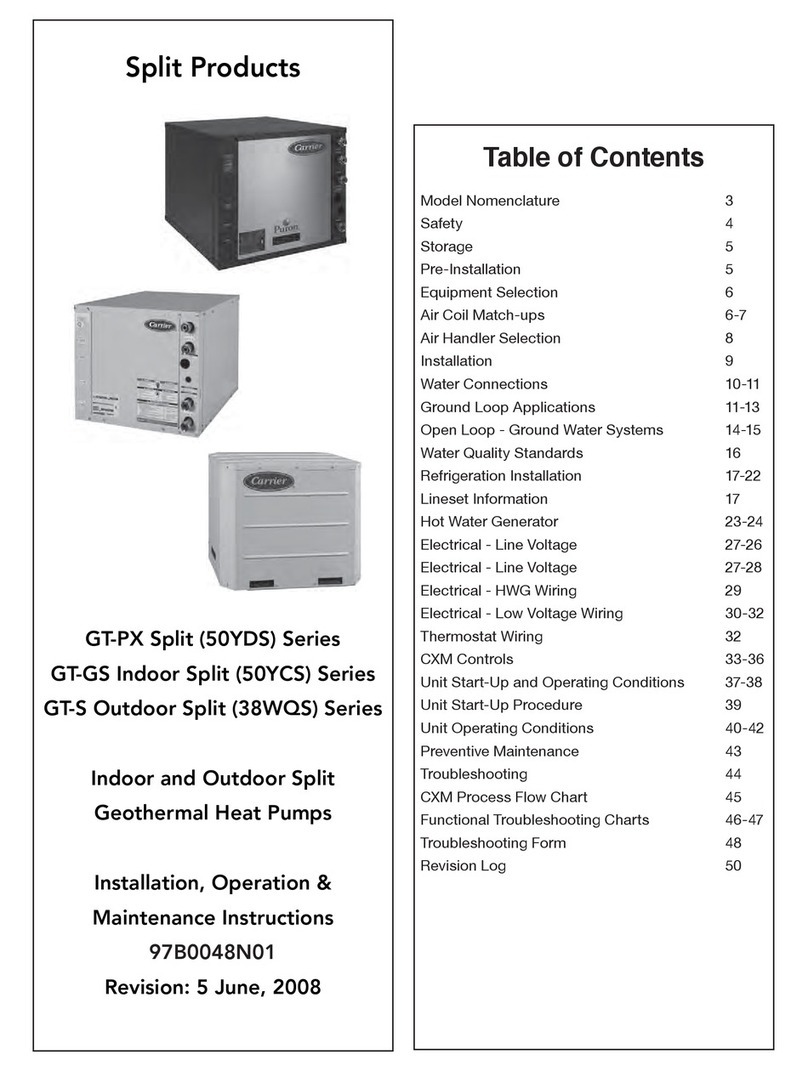

Table of contents

Page

Features/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1, 2

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

ARI Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,5

Base Unit Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Typical Wiring Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-20

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22,23

MODEL NUMBER NOMENCLATURE

50ZH 030 5

Model No.

50ZH — Single Packaged

--------- -Heat Pump Unit

Nominal Cooling Capacity

030

– 2-1/2 Tons

036

– 3 Tons

042

– 3-1/2 Tons

048

– 4 Tons

060

– 5 Tons

Electrical Supply

5 — 208/230-3-60

6 — 460-3-60

01AD

Packaging

Series

Options

- -

– Wire Grille

AD

– Louvered Grille

BT

– Wire Grille and vinyl-coated

outdoor coil fin

XT

– Louvered Grille and vinyl-coated

outdoor coil fin

CC

– Wire Grille, AL indoor and CU/CU

outdoor coil

CU

– Wire Grille, CU/CU indoor and

outdoor coils

AC

– Louvered Grille, AL indoor and

CU/CU outdoor coil

AU

– Louvered Grille, CU/CU indoor and

outdoor coils

TP

– Tin-Plated Indoor Coil Hairpins

(Refer to current Price Page for

additional combination of options)