FREIGHT DAMAGES AND SHORTAGES

The cabinet was inspected and

packaged at the factory, and should

arrive in excellent condition.The transportation company

or other parties involved in the shipment are responsible

for loss and/or damage. Always make an inspection

before and after uncrating. Inspect the crated unit(s)

before locating (preferably at the point of unloading by

the transportation company).

INSPECTING FOR DAMAGES

Always use care when removing shipping

tape, blocks, pads, hardware or other material

until you are satisfied that the unit is completely opera-

tional.

Check the cartons or containers. If these are damaged

in any way, open them and inspect the contents in the

driver’s presence. If damage is detected:

1. Have the driver note the nature and extent of the

damage on the freight bill.

2. Notify the transportation company’s office to request

an inspection. Carrier claim policies usually require

inspections to be made within 15 days of delivery.

3. If damage is noticed, file a claim with the transporta-

tion company.

FILING A CLAIM

File a claim for loss at once with the transportation

company for:

A. A cash adjustment; B. Repairs; or C. Replacement

When filing your claim, retain all packaging materials

and receipts.

HANDLING THE CABINET

The refrigeration system of the cabinet is

designed to operate with the cabinet located

on a level surface. Do not tilt the cabinet more than

10° to any side. If the cabinet must be tilted on an

angle for handling or moving purposes, allow it to sit in

an upright position 30 minutes prior to starting.

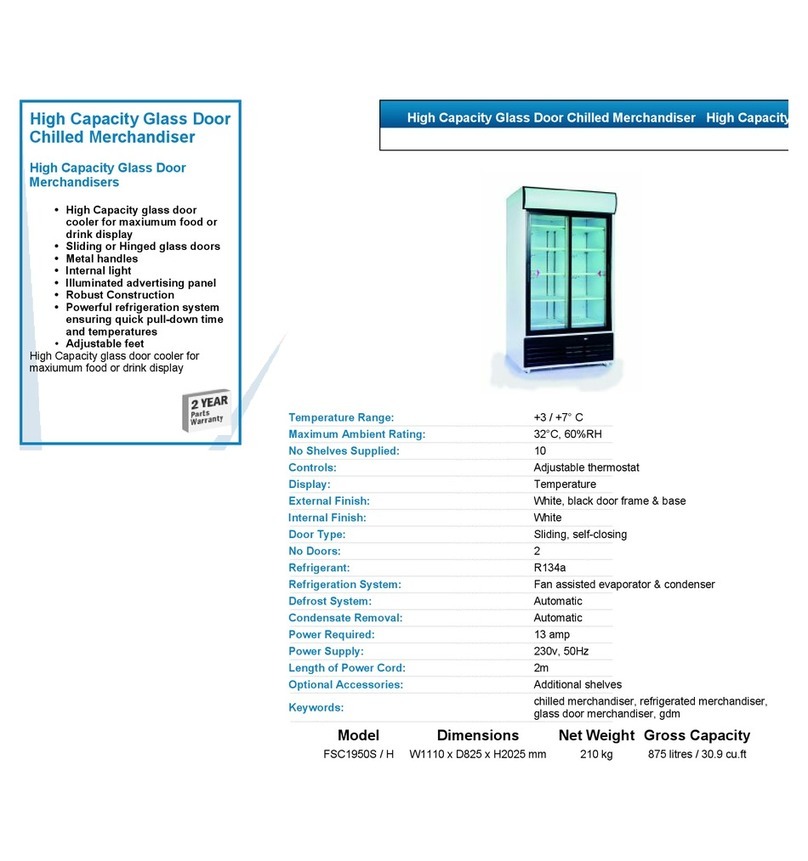

CHOOSING A LOCATION

This model cabinet should be situated to allow proper air

circulation. Cabinets require a 2" minimum clearance

behind for proper air circulation.

The cabinet must be installed on a sturdy, solid, level

floor.

The cabinet must be located so it can be plugged or

wired into a properly grounded three-prong electrical

outlet of 115/220 volt, 60 hz.The electrical outlet should

not be controlled by a wall switch which might be turned

off accidentally.

UNCRATING THE CABINET

The cabinet should be moved as close as possible to

the operating location before removing crate base. Be

sure to follow the steps in the “INSPECTING FOR

DAMAGES” instructions.

INSTALLING THE CABINET

After removing the skid from the cabinet, slide cabinet

into location.Level cabinet to insure proper draining of

the defrost water.

To meet NSF requirements, these cabinets must be

sealed to the floor with an NSF or FDA approved

sealant.

Remove the front grill from cabinet. Remove front hold

down bolts and pull unit out of cabinet. Remove ship-

ping band from compressor. Be sure that the compres-

sor “floats” freely on the compressor springs. Check

refrigeration lines to see that they are “free” and no

damage was done in shipping.Check fan blade for free

operation.

Check voltage and amp draw on the serial plate to

determine proper fuse and line size.Voltage should be

checked at the compressor terminals as the compres-

sor is starting, to determine if there is excessive “volt-

age drop.” This voltage drop should not exceed 10% of

the rated compressor voltage. If the voltage reads 115

or 230 with no load and it drops below 103 or 208 when

the compressor tries to start, it is an indication that the

supply wiring is too small in size or too long in length.

It is recommended that a separate circuit be run for each

cabinet to prevent the possibility of another appliance

blowing a fuse causing subsequent loss of product.

SECTION I – HANDLING & INSTALLATION

6INTRODUCTION

NOTE:

IMPORTANT:

NOTE: