Carpentry Procedures

Case Line-Up

Before starting the case line-up, review the

store layout floorplans and survey the areas

where case line-ups are going to be installed.

WARNING

These cases are very heavy and require

two or more people to move and/or posi-

tion them. Improper handling of these

cases could result in personal injury.

1. Snap chalk lines where the front and rear

legs or base rails of the case are to be

located for the entire line-up.

NOTE

Front and rear edges of legs and/or base

rails should always be used to line-up

cases. Cases with legs have built-in

leveling adjustment capabilities. Cases

with base rails use 6” shims that allow

adjoining ends of cases to be shimmed

together.

2. Cases with legs are shipped on skids.

Using a proper lifting device, move case

on skid to approximate installation loca-

tion. Remove case from skid and install

legs to base. Make sure all legs are

completely threaded into the base to

properly secure them. Thread out bottom

leg insert, up to 1 1/2”, to level the case.

INSTALLATION PROCEDURES

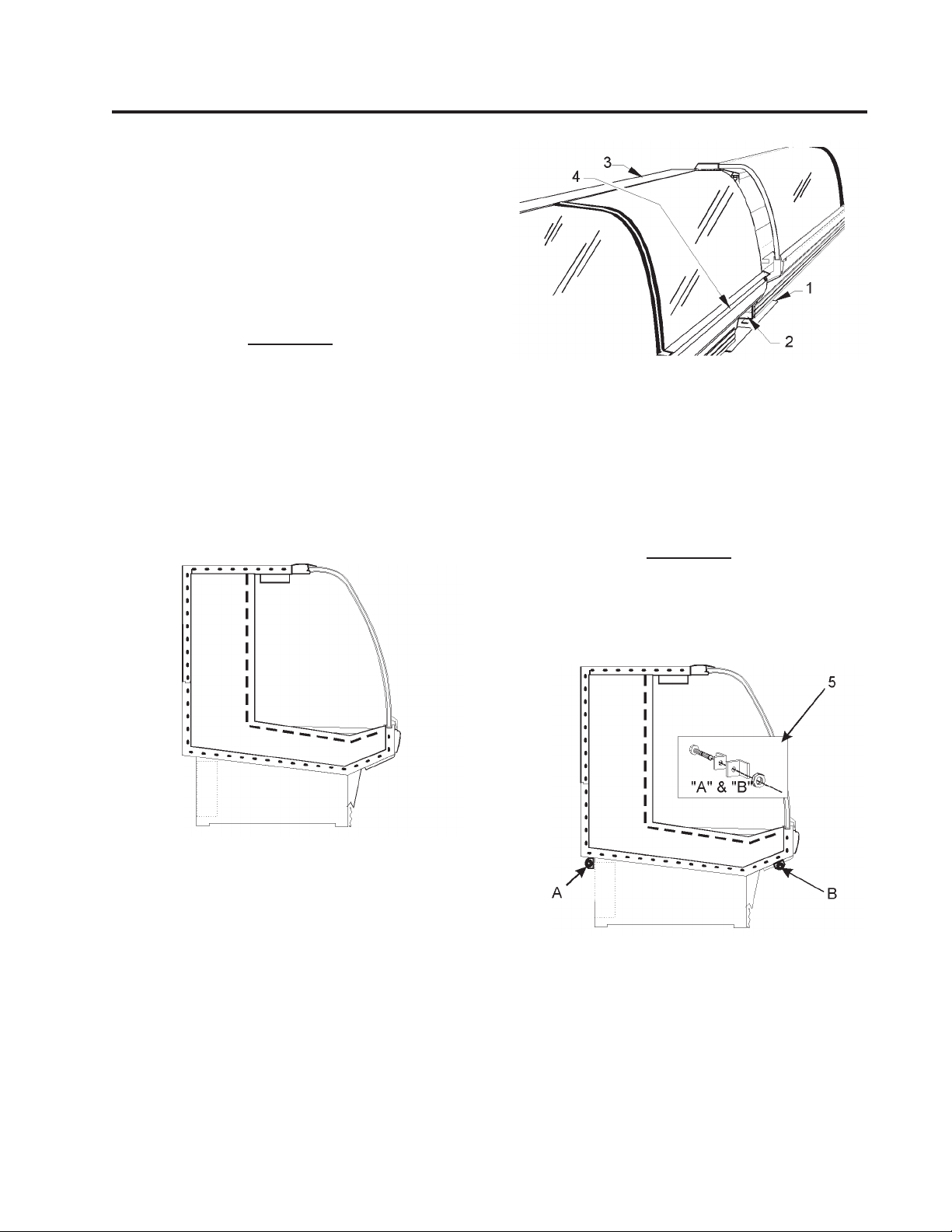

WARNING

The raised front glass projects in front of

the case and could cause personal injury

to workers, operators and/or customers.

• Do not remove orange warning tags

from front edge of lift glass.

• Do not leave lift glass raised and

unattended.

• Know where the front edge of the

raised glass is when working near it.

This case is designed so the front glass can

be raised for cleaning and merchandising

only. It is recommended that any cleaning or

merchandising be done when the store is

closed. If this is not possible, it should be

done at a time when customer traffic is low.

The raised glass should not be left unattended

and should be lowered whenever leaving the

case.

The glass front is marked with orange warning

tags to make it noticeable when in the raised

position. Do not remove the orange warning

tags.

NLBR, NLBN, NLBS

Page 8 April, 2007