II

Table of Contents

ZERO ZONE WARRANTY......................................................................................1

INTRODUCTION.....................................................................................................2

Important User Information ..............................................................................2

Manufacturer.....................................................................................................2

Intended Use.....................................................................................................2

Display Case Models........................................................................................2

Case Features..................................................................................................3

Testing Standards.............................................................................................3

INSTALLATION & OPERATION.............................................................................4

Delivery Inspection............................................................................................4

Packaging.........................................................................................................4

Location............................................................................................................4

Moving Cases...................................................................................................5

Optional Bases...........................................................................................5

Leveling.............................................................................................................6

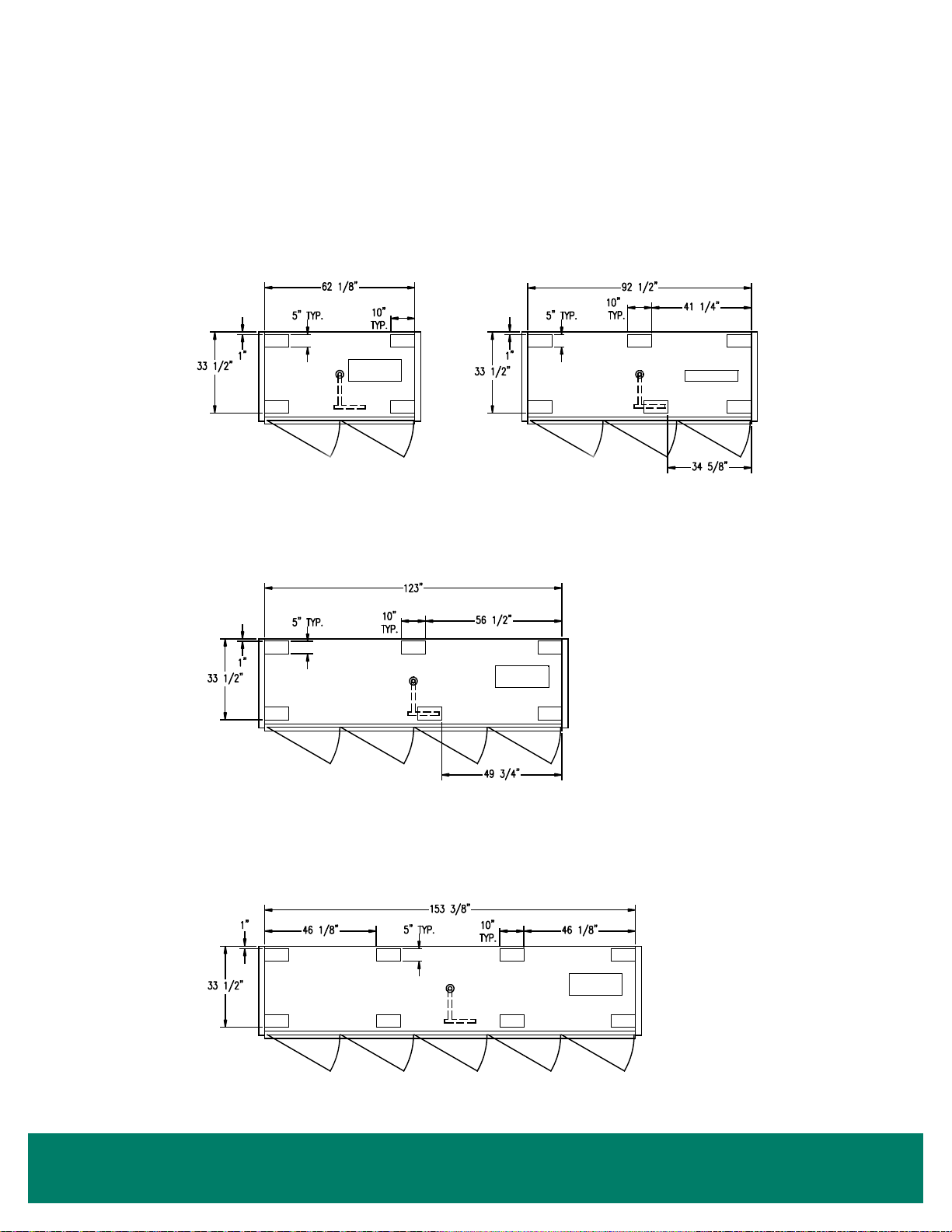

LineupAssembly ............................................................................................13

Ultra Narrow CaseAnchoring.........................................................................14

Door Leveling (Door Sag/Sawtooth)...............................................................17

Bottom Mounting Plate.............................................................................18

Top Mounting Plate...................................................................................18

Drain...............................................................................................................18

Condensate Removal System........................................................................18

Kickplates........................................................................................................19

Bumper...........................................................................................................19

Top Trim..........................................................................................................19

CoolView®Doors.............................................................................................19

CoolArc™Door Handles ...........................................................................19

Hold-Open Bracket...................................................................................19

Door Gasket.............................................................................................20

Door Closer /Adjusting Door Tension ......................................................20

Removing a Door.....................................................................................20

Installing a Door.......................................................................................20

Rear Load Cases............................................................................................21

Shelves & Stocking Product............................................................................21

REFRIGERATION.................................................................................................22

Mechanical Components................................................................................22

Evaporator Fans.......................................................................................22

Expansion Valve.......................................................................................22

Additional Valves......................................................................................22

Refrigerant Piping...........................................................................................22

Leak Check, Evacuation, & Charging.............................................................22

Operation Set Points.......................................................................................23

Defrost ...........................................................................................................23

Case Thermometers.......................................................................................23

ELECTRICAL........................................................................................................24

General...........................................................................................................24

MAINTENANCE....................................................................................................25

Cleaning..........................................................................................................25

Under Case Floor Cleaning (NSF)...........................................................25

When installing a Crystal Merchandiser®in a Hybrid Merchandiser™ conguration, refer to both this manual

and the Hybrid™ Installation & Operation Manual.