Page 4 of 21

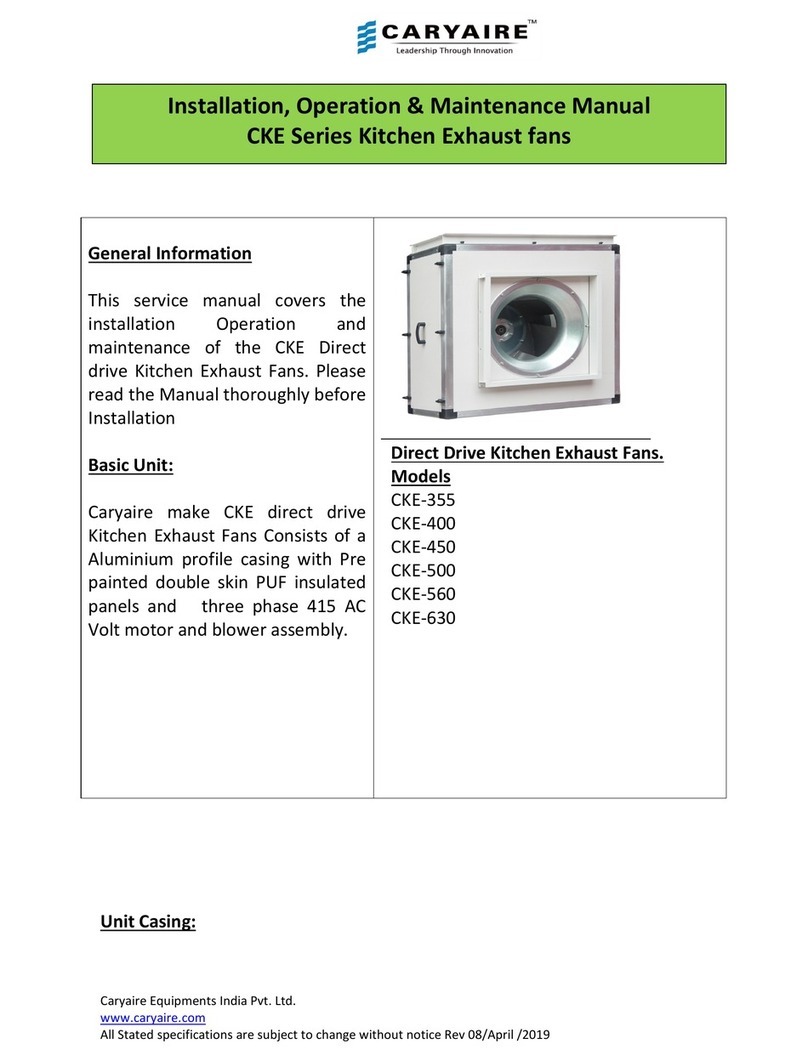

Technical Information

Fan size in

Diameter

8 Ft. 10 Ft. 12 Ft. 16 Ft. 20 Ft. 24 Ft.

2.4M 3.0M 3.7M 4.9M 6.1M 7.3M

Motor Power 1.5 HP 1.5 HP 1.5 HP 2 HP 2 HP 2 HP

1.1 KW 1.1 KW 1.1 KW 1.5 KW 1.5 KW 1.5 KW

Ampere

At 400 volt

2.42 A 2.42 A 2.42 A 3.35 A 3.35 A 3.35 A

Speed (RPM) 154 140 123 73 63 56

Air flow

CMH(Approx.)

64 500 1 56 000 2 06 000 2 80 500 5 04 900 612000

Maximum

Coverage

Diameter

9.4M/30.8Ft

15.8M/51.8Ft

21.3M/69.9Ft 36M/118Ft 42M/138Ft

50M/164Ft

Weight (Kg) 98 104 108 124 132 140

Important information:-

-Fan for se wareho ses, A to Plants, Distrib tion Centers, Man fact ring nits, Gyms,

Banq et Halls, Retail Stores and Worship Centers and all areas where air ventilation and

air circ lation req ire.

-This appliance is not intended for se by persons (incl ding children) with red ced

physical, sensory or mental capabilities, or lack of experience and knowledge, nless

they have been given s pervision or instr ction concerning se of the appliance by a

person responsible for their safety.

-Use CE certify cable for better performance and better safety.

-If the s pply cord is damaged, it m st be replaced by the man fact rer, its service agent

or similarly q alified persons in order to avoid a hazard.

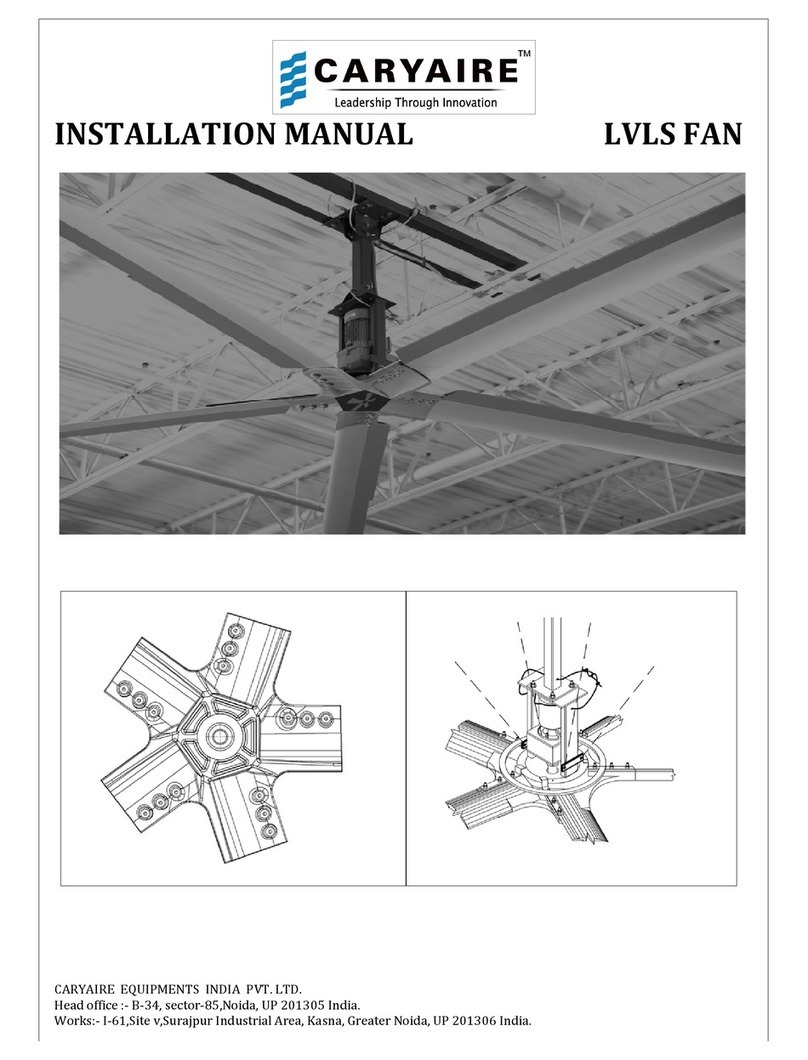

Tools Req ired For Installation

•Level indicator

•Cable C tters(for stainless steel aircraft cables)

•Ratchet or Impact g n

•Basic Metric socket set

•Basic metric wrench set

•Lifting Device or Scaffolding