VFD CONTROLLER :

[ MODEL SK 500E-151-340-

Generally Electrical installation is done before

installing the Fan. Number of wires to be used

will depend on whether the VFD i

three phase. Wire Size should adhere to the

Local electrical codes. However connection

between VFD & Fan will need 4 wires. Whether

the Input to VFD is Single phase or three phase

power to the fan will always be three phase.

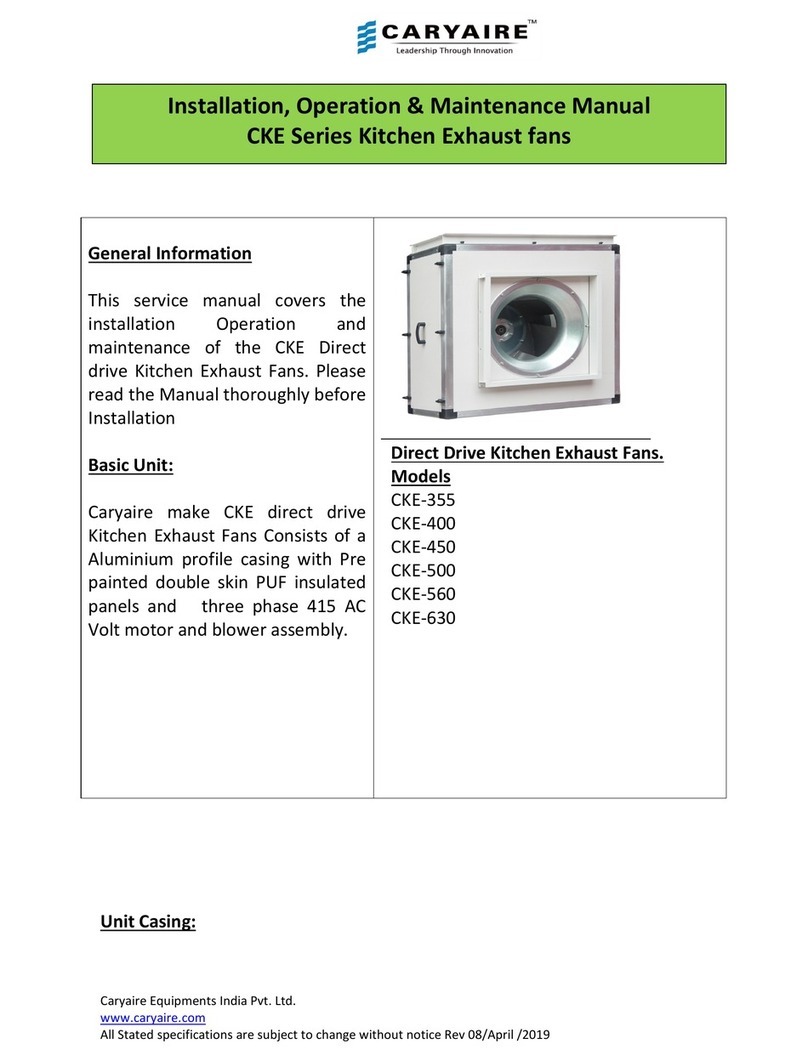

Type

Enclosure:

Part number:

Dimensions (L1*B*T in [mm])

A]

Generally Electrical installation is done before

installing the Fan. Number of wires to be used

will depend on whether the VFD i

s single or

three phase. Wire Size should adhere to the

Local electrical codes. However connection

between VFD & Fan will need 4 wires. Whether

the Input to VFD is Single phase or three phase

power to the fan will always be three phase.

SK 500E-151-340-A

IP20

275420150

Dimensions (L1*B*T in [mm])

•

four parameter sets selectable on

•Sensor less vector control

•

Automatic motor identification

•

5 Digital inputs 2 Analog inputs

•

2 Relay outputs 1 Analog output

•

Integrated brake chopper and dynamic

brake control

•RS232 and RS485 compati

RJ12 connector

Page 7 of 19

FIG-5

four parameter sets selectable on

-line

Automatic motor identification

5 Digital inputs 2 Analog inputs

2 Relay outputs 1 Analog output

Integrated brake chopper and dynamic