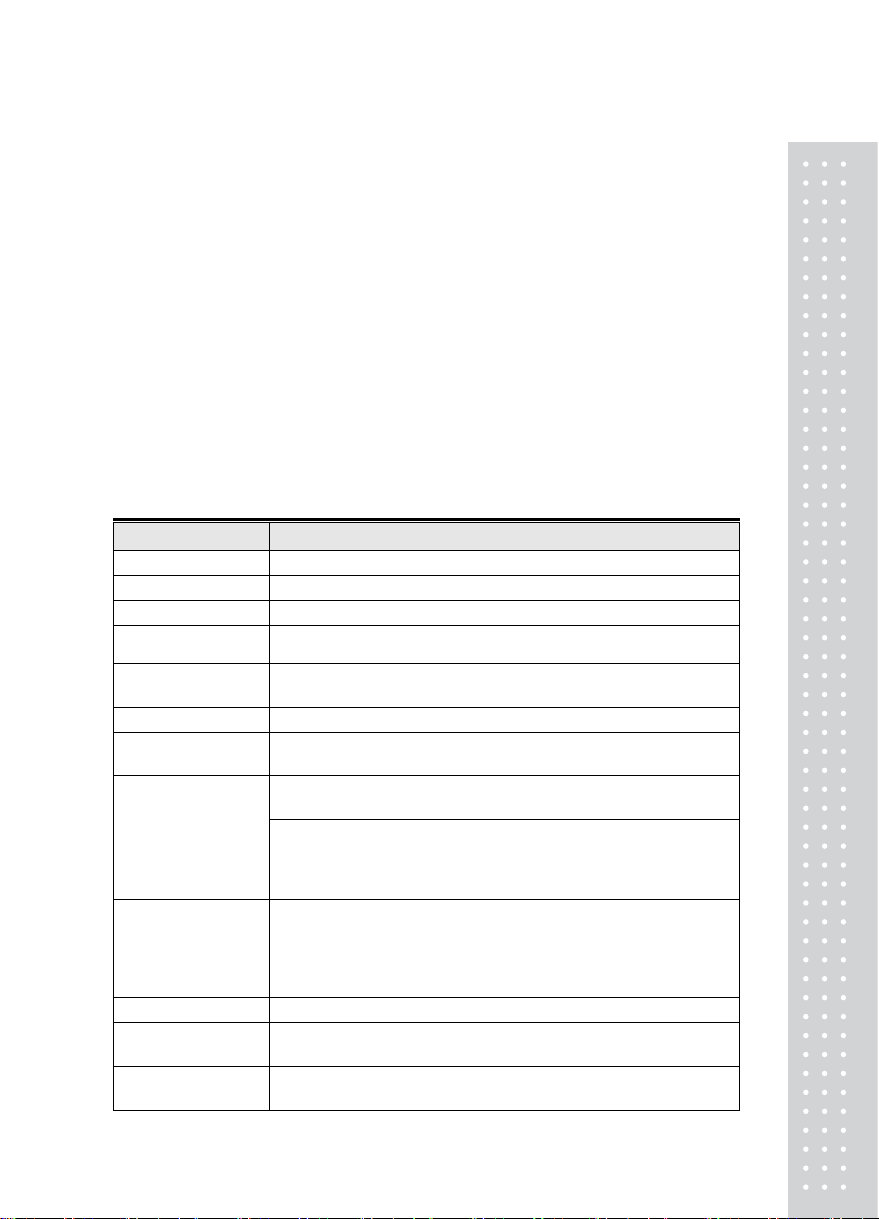

180°, 270° rotatable

Bitmap fonts 8 times expandable in horizontal and vertical

directions

Scalable fonts 90°, 180°, 270° rotatable

Download Fonts

Bitmap fonts 90°, 180°, 270° rotatable, single characters 90°,

180°, 270° rotatable

Asian fonts 90°, 180°, 270° rotatable and 8 times expandable in

horizontal and vertical directions

Scalable fonts 90°, 180°, 270° rotatable

1D Barcode:

Code 39, Code 93, Code 128 (subset A, B, C), UCC/EAN-128 K-

Mart, UCC/EAN-128, UPC A / E (add on 2 & 5), I2 of 5, I2 of 5

with Shipping Bearer Bars, EAN 8 / 13 (add on 2 & 5), Codabar,

Post NET, EAN 128, DUN 14,

MaxiCode, HIBC, Plessey, Random Weight, Telepen, FIM,

China Postal Code, RPS 128, GS1 Data Bar

Barcodes

2D Barcode:

PDF 417, Datamatrix code, matrix code, QR code, Micro QR code

Code Pages

CODEPAGE 437, 850, 851, 852, 855, 857, 860, 861, 862, 863,

865, 866, 869, 737

WINDOWS 1250, 1251, 1252, 1253, 1254, 1255

Unicode (UTF8, UTF16)

Graphics Resident graphic file types are BMP and PCX, other graphic

formats are downloadable from the software

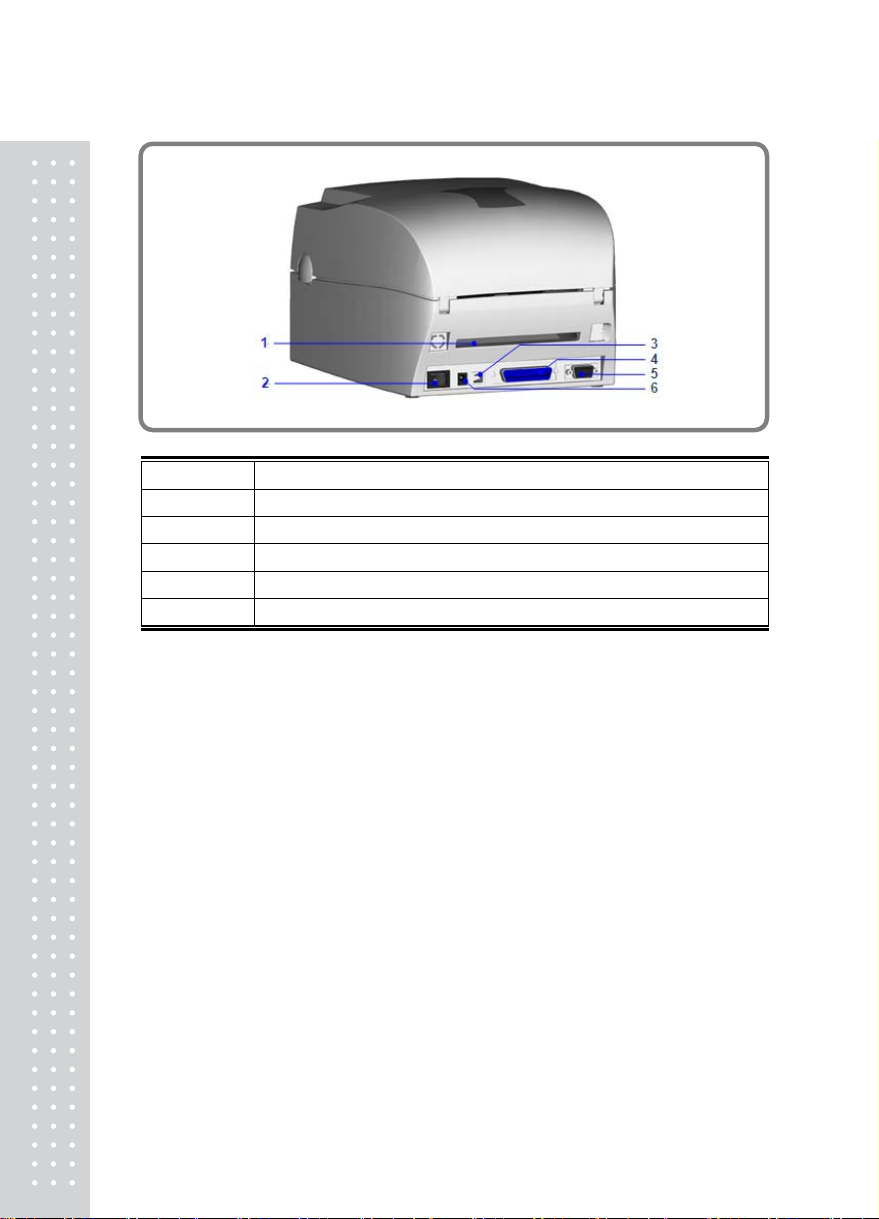

Interfaces Serial Port : RS-232 (DB-9)

USB Port : V2.0

Parallel Port : Centronics 36-pin

Control Panel Two bi-color status-LEDs: Ready, Status

Control key: FEED

Power 100-240VAC, 50/60 Hz

Environment Operation temperature: 41°F to 104°F (5°C to 40°C)

Storage temperature: -4°F to 122°F (-20°C to 50°C)

Humidity Operation: 30-85%, non-condensing.

Storage: 10-90%, non-condensing.

Agency

Approvals CE(EMC), FCC Class A, CB, cUL, CCC

Dimension Length: 11.2” (285 mm)

Height: 6.8” (171 mm)

Width: 8.9” (226 mm)

Weight 2.72kg

Options

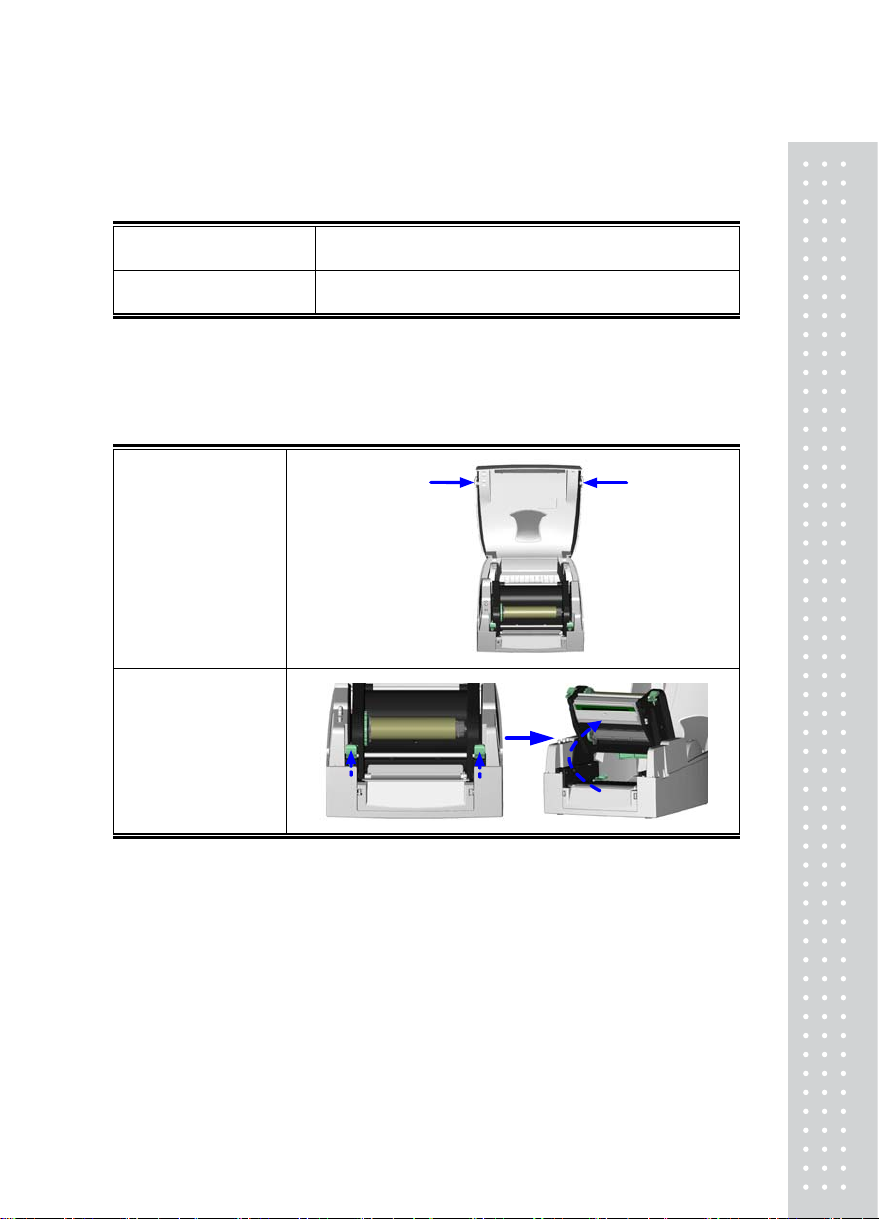

Cutter

Label Stripper

External label roll holder for 10” (250 mm) O.D. label rolls

CF card adapter with real time clock (max. 1GB CF card)

* Specifications are subject to change without notice.

6