II

PREPARING FOR SNOW REMOVAL

Disengage the attachment drive

clutch when starting engine and

when transporting the snow

blower. Before the first snow-

fall, the area in which snow re-

moval is to take place should

be cleared of all stones, sticks,

etc., which might be picked up

by the snowblower. OBSTACLES

SUCH AS DRTVEWAY MARKERS,

WATER OR GAS SHUT OFFS,

ETC" SHOULD BE MARKED SO THEIR LO-

CATIONS UNDER THE SNOW ARE VERY

OBVIOUS.

To become familiar with the controls, op-

erate the tractor and snow blower in a clear

area before removing snow. The more

familiar you become with the snow blower,

the better results you wiil have in its use.

SNOW CONDITIONS

Snow removal conditions vary so greatly

from the first light fiuffy snowfall to wet

or heavy snow that operating instructions

must be flexible. The operator must op-

erate according to depth of snow, wind di-

rection, temperature, and surface conditions.

The auger speed and blowing distance are

directly related to the engine speed. For

maximum removal volume and distance,

maintain high engine RPM (three -quarters

to fuII governed throttte). Operatingatlower

throttle settings will reduce the blowing dis-

tance and increase fuel economy. Always

operate the tractor in low range for safe and

efficient snow removal. The speed control

lever should be operated to provide a ground

speed most compatible with the snow re-

moval conditions.

In extremely deep snow, raise snow blower

into transport and remove top layer first.

Lower the snow blower to the ground and

repeat process to remove the balance of

snow. Working with repeated passes into

and out of drifts will eventually move even

the deepest of snow piles.

A light coat of wax applied to the inside

surfaces of the discharge chute anddeflector

wiII help to prevent snow and slush from

sticking. The inside of chute and deflector

should be waxed several times during the

snow removal season. Use any good com-

mercial grade of paste wax or spray sili-

cone which is available from your dealer

or from your local hardware store.

Allow ample engine warm up time before

starting snow removal.

Best results are obtained when snow is re-

moved as soon as possible aJter it falls.

Check each item covered in the "ADJUST-

MENTS" and "MAINTENANCE" sections of

this manual before operating the snow blower.

AEJUSTMENTS

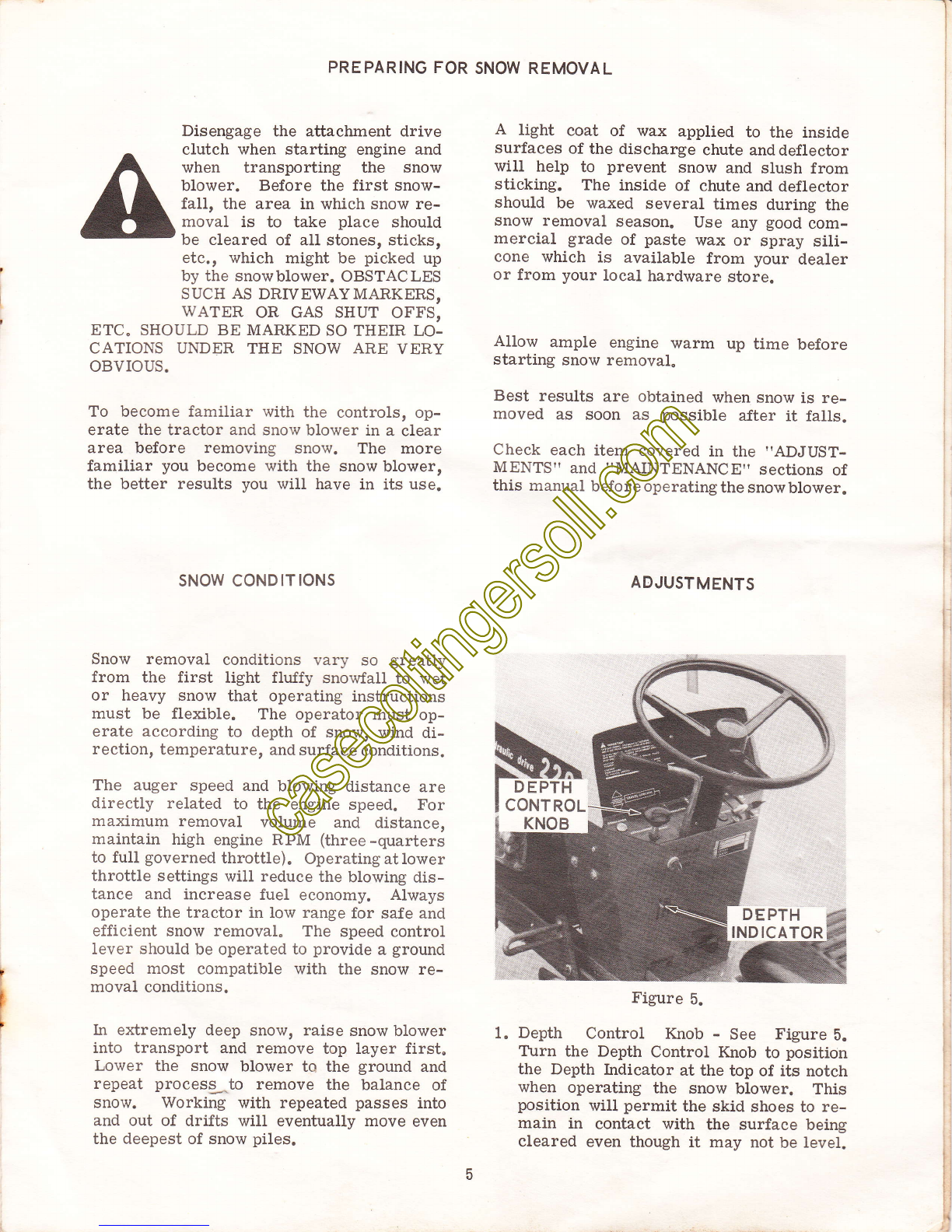

Figure 5.

1. Depth Control Knob - See Figure 5.

Ttrrn the Depth Control Knob to position

the Depth Indicator at the top of its notch

when operating the snow blower. This

position will permit the skid shoes to re-

main in contact with the surface being

cleared even though it may not be level.

DEPTH

INDICATOR