index

The language manual is available on the www.castellarisrl.com

Use and maintenance manual: www.castellarisrl.com

User and maintenance manual: www.castellarisrl.com

ΕΓΧΕΙΡΙΔΙΟ ΧΡΗΣΗΣ ΚΑΙ ΣΥΝΤΗΡΗΣΗΣ: www.castellarisrl.com

1. DESCRIPTION OF THE GENERAL CHARACTERISTICS OF THE MACHINE ............................. 3

1.1 Purpose of the manual ................................................................................................. 3

1.2 Machine identification ................................................................................................. 3

1.3 Machine description and technical data......................................................................... 3

1.4 Subjects to whom the manual is addressed.................................................................... 4

1.5 Intended and unforeseen uses of the machine ............................................................... 4

1.6 Protections and safety devices ...................................................................................... 4

1.7 Risks arising from the use of the machine ...................................................................... 5

1.7.1 Noise risk..................................................................................................................................5

1.7.2 Vibration risk............................................................................................................................5

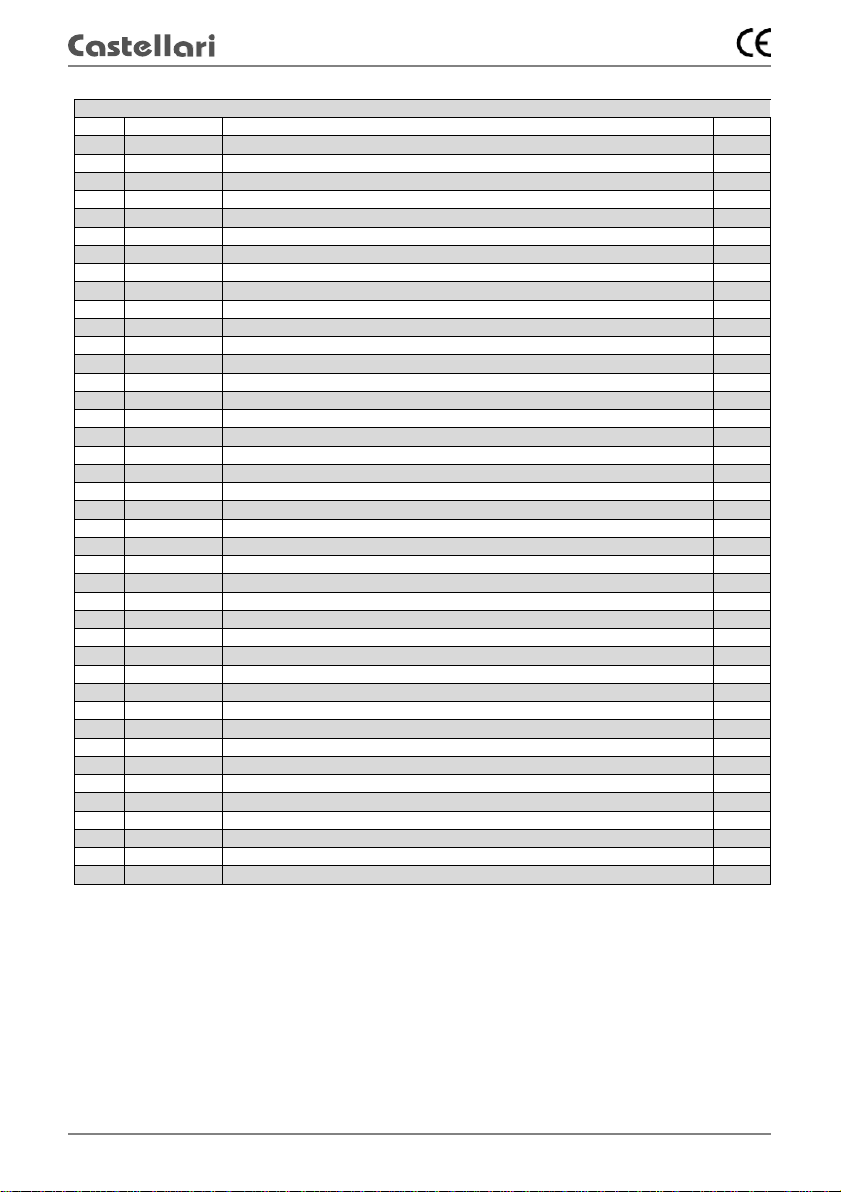

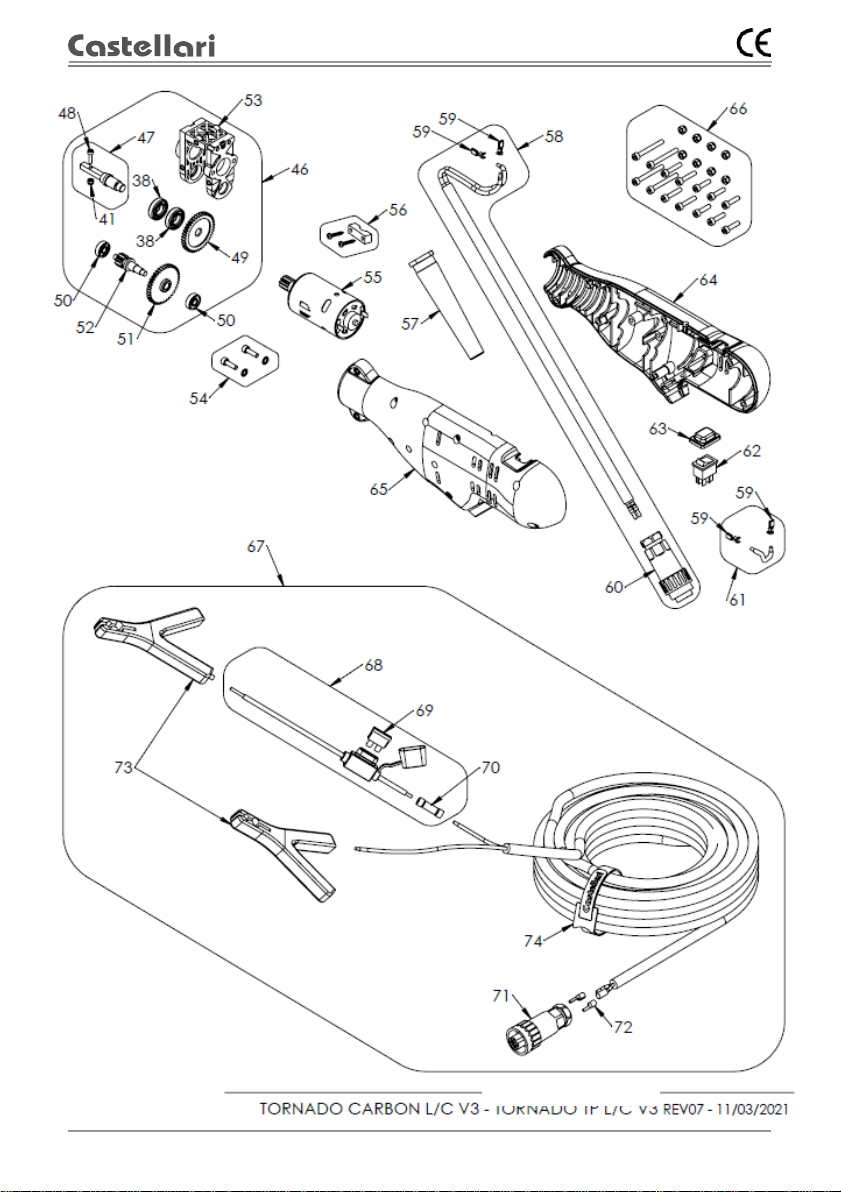

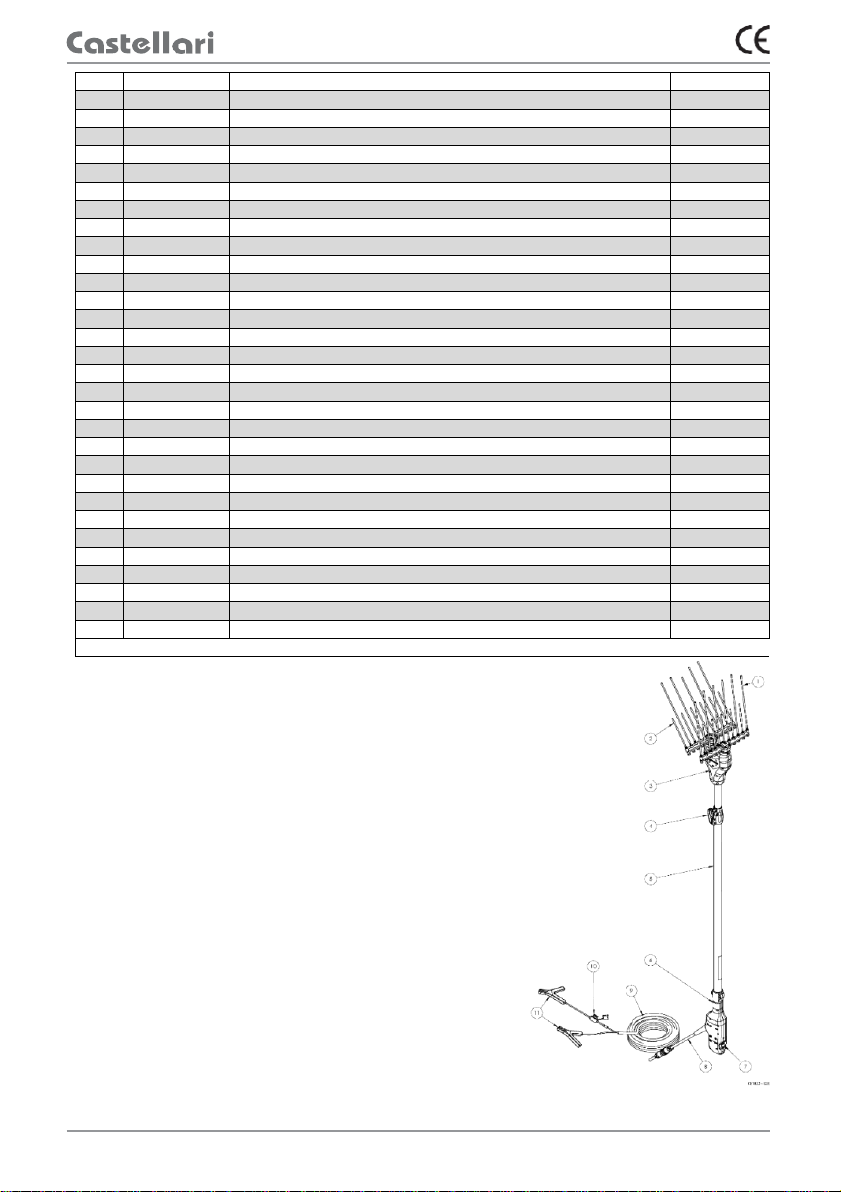

1.8 Components.............................................................................................................................6

2. SAFETY AND PREVENTION ......................................................................................... 10

2.1. Safety signals (pictograms) ......................................................................................... 10

2.2. General safety standards............................................................................................ 10

2.3. Safety in use and maintenance.................................................................................... 11

2.3.1.Safety in use ...........................................................................................................................11

2.3.2.Maintenance safety ...............................................................................................................11

2.4. Ecology and pollution................................................................................................. 12

2.4.1.Waste management ..............................................................................................................12

2.4.2.User information....................................................................................................................12

3. USE........................................................................................................................... 12

3.1 Handling and transport................................................................................................. 12

3.2 Before use................................................................................................................. 12

3.3 connection................................................................................................................ 14

3.4 Use of the machine .................................................................................................... 14

4 MAINTENANCE AND CLEANING.................................................................................. 15

4.1 Routine maintenance ................................................................................................... 15

4.2 Assembly and disassembly of combs ........................................................................... 15

4.3 Cleaning and lubrication of the machine ...................................................................... 16

4.4 Set-aside................................................................................................................... 16

4.5 Dismantling of the machine ........................................................................................ 16

4.6 Spare parts................................................................................................................ 16

5 WARRANTY CONDITIONS........................................................................................... 16

5.2 Exclusion from warranty............................................................................................. 17

6 DECLARATION OF CONFORMITY................................................................................. 17