This is a Safety Alert Symbol -

When you see this symbol in the manual, look for the following signal words &

be alert to the potential for personal injury or property damage.

Warns of potential hazards that WILL cause serious personal injury, death or property damage.

Warns of potential hazards that CAN cause serious personal injury, death or property damage.

Warns of potential hazards that WILL or CAN cause minor personal injury, death or property damage.

Indicates special instructions that MUST be followed but not related to hazards.

To avoid serious or fatal personal injury or major property damage,

read and follow all safety and operation instructions in the manual.

This manual is intended to assist in the installation and operation of this unit.

Do not attempt to operate this unit without reading and understanding this manual.

DANGER

WARNING

IMPORTANT

CAUTION

Safety Information | 1

General Safety

To avoid the risk of serious bodily injury and property damage, read safety instructions carefully before installing

this system. Follow all local and/or national plumbing and electrical codes when installing.

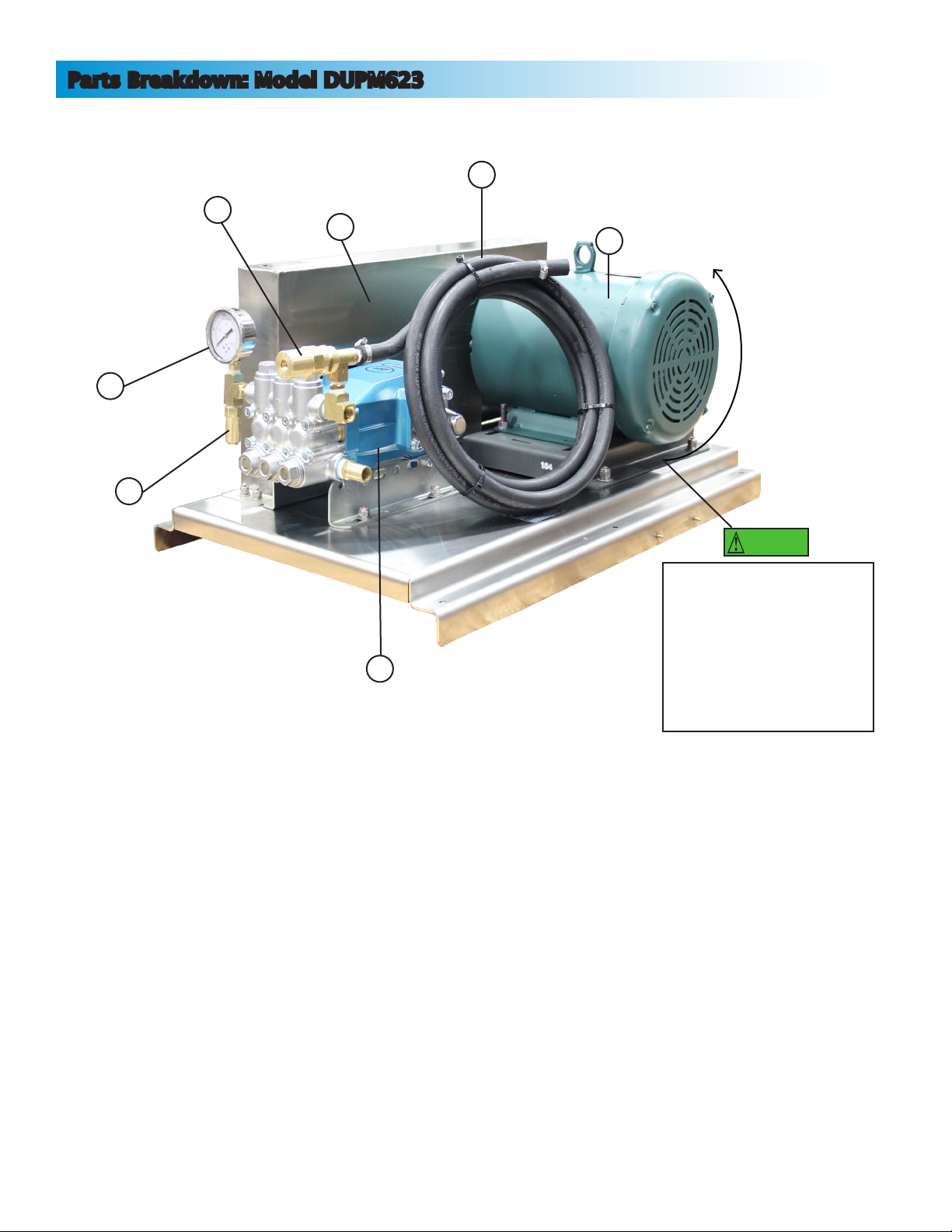

Do Not Allow System or Components to Freeze.

To do so may damage the system and will void the warranty.

Never Run the System Dry.

Running the unit dry (without fluid) can damage internal parts, overheat pump (which can cause

burns to people handling or servicing the pump), and will void the warranty.

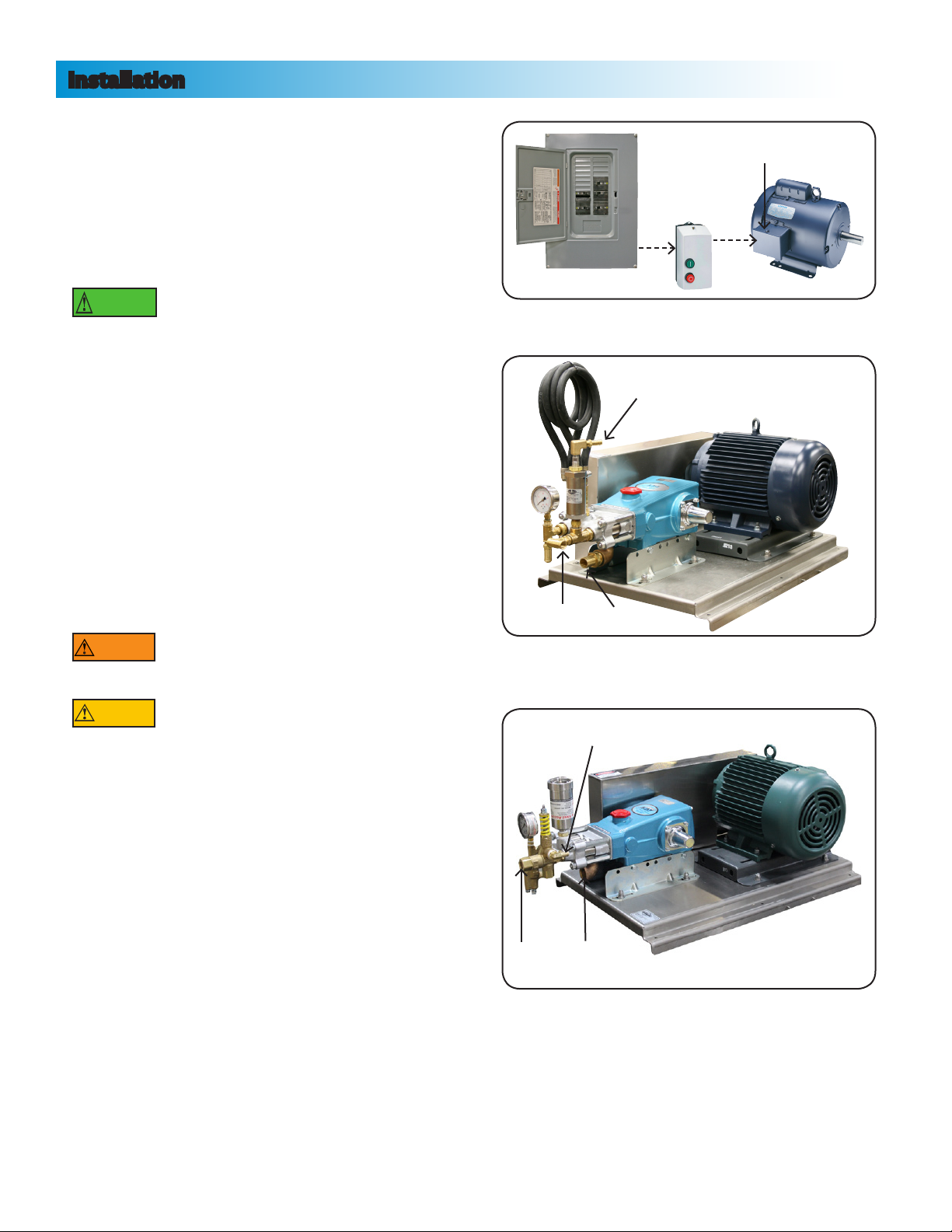

Risk of Electric Shock.

Keep the unit dry at all times -

Do not wash the motor or electrical panel or allow the unit to sit in standing water.

Use only Ground Fault Circuit Interrupter (GFCI) protected grounded outlet for the cord plug.

If you must use an extension cord, use only UL approved indoor/outdoor, 3-wire, grounding

type cords. The cord must be rated to support amp draw. Do not allow any part of cord or

receptacle ends to sit in water.

To avoid fatal shocks, proceed as follows if service is needed:

A. Turn off water to the system.

B. Disconnect the power at main electrical service before unplugging the unit.

C. Ground the electrical outlet box.

D. Take extreme care when changing fuses.

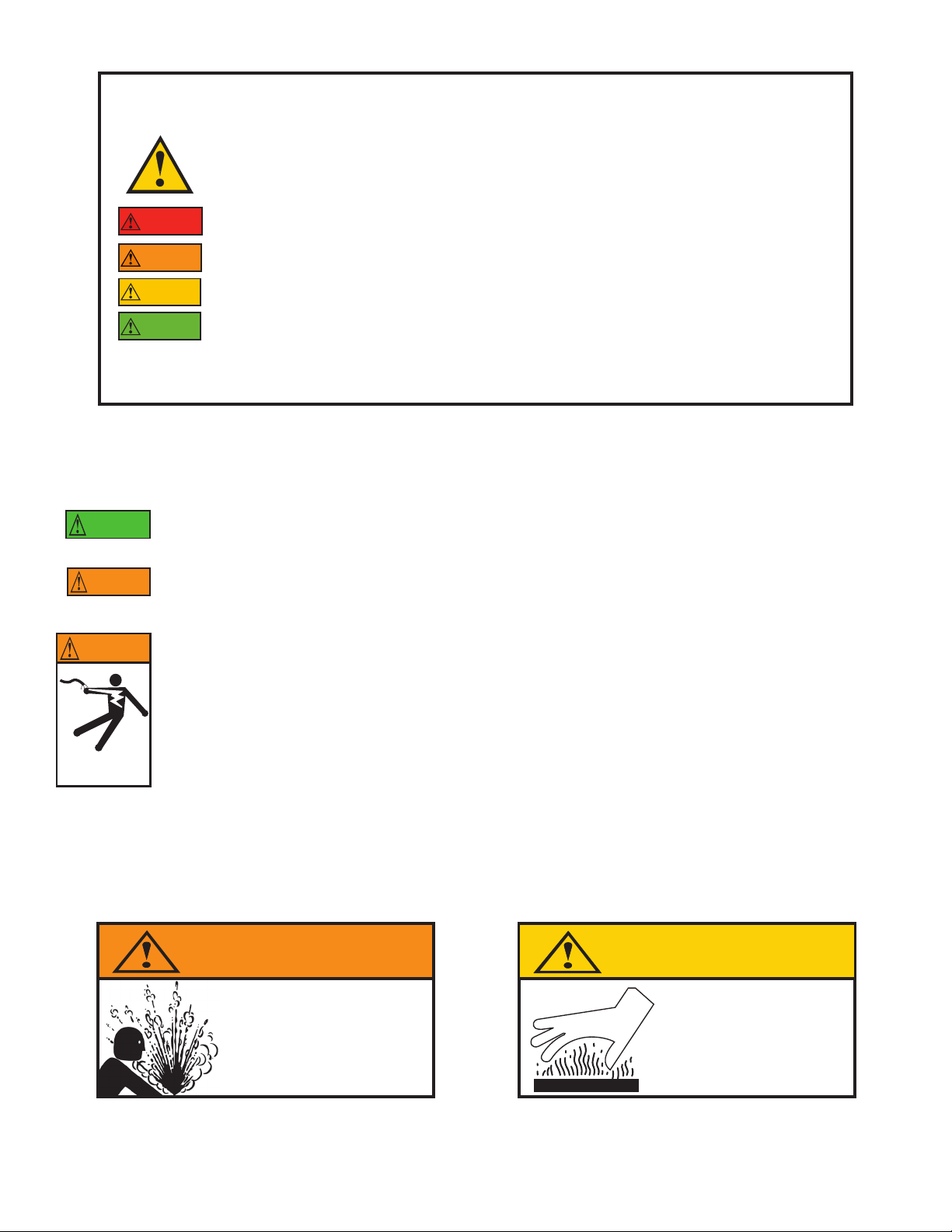

WARNING

Hazardous voltage

can shock, burn

or cause death.

IMPORTANT

WARNING

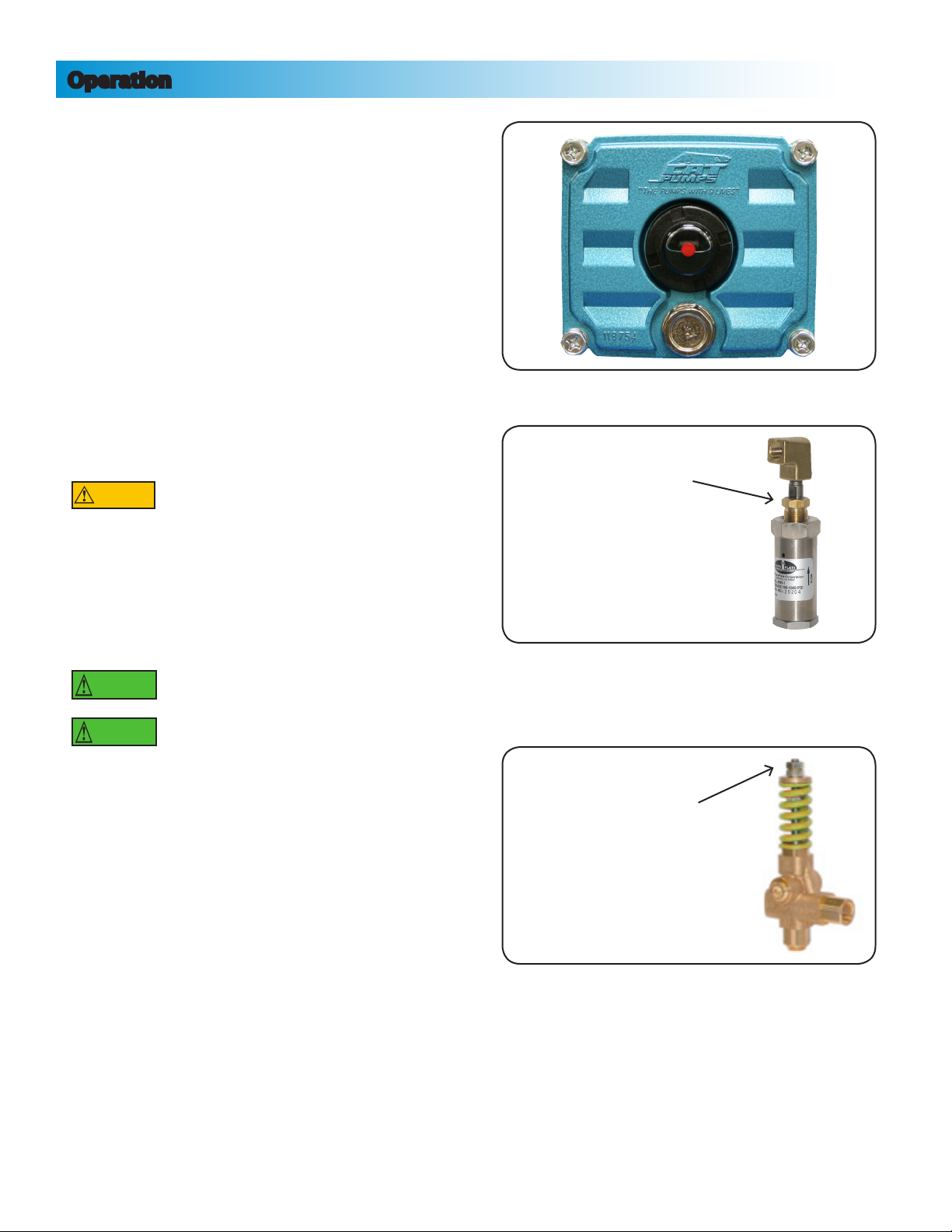

Modern motors can operate at high temperatures.

To avoid burns when servicing pump, allow it

to cool for 20 minutes after shutdown before

handling.

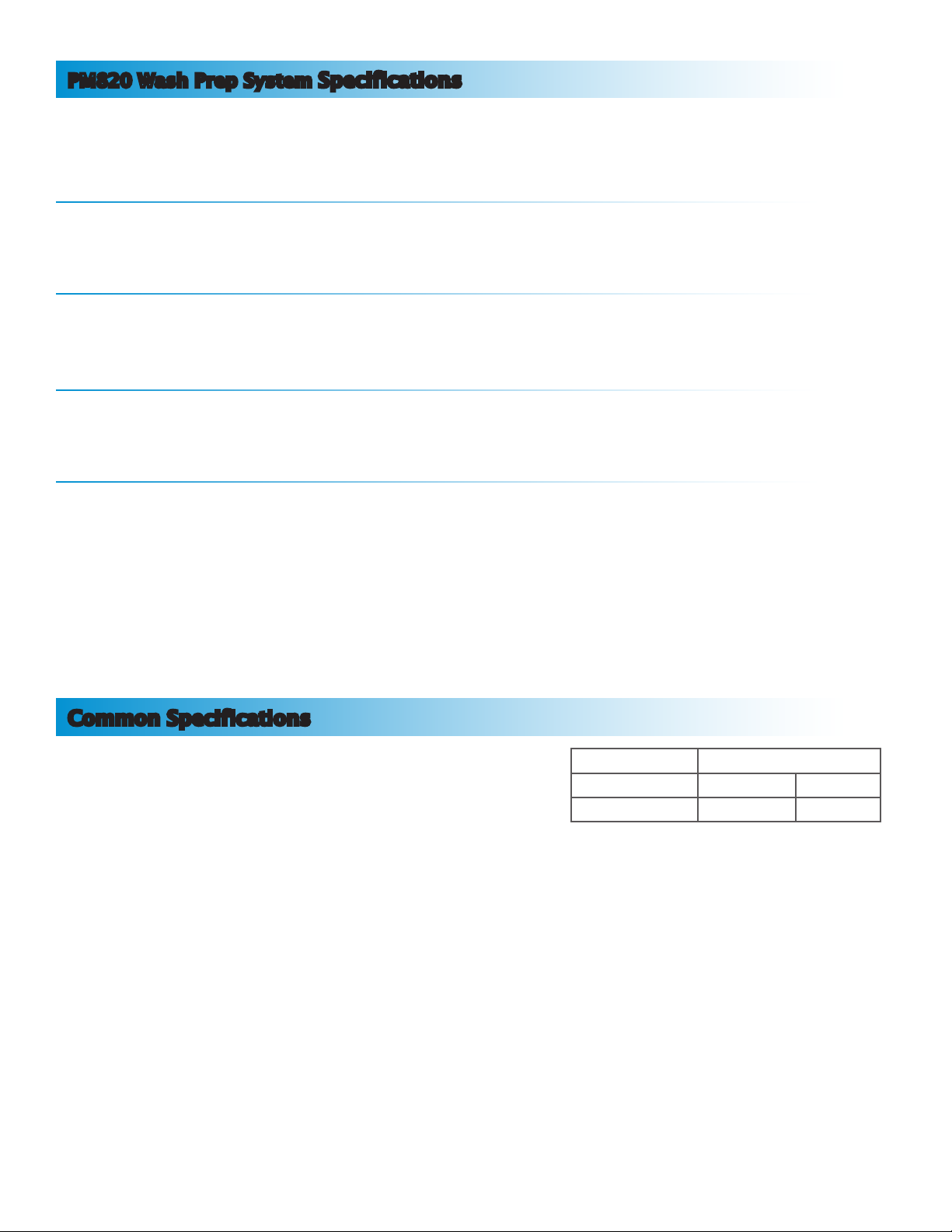

Do not run the unit with discharge shut off, as

hose may burst or damage may occur.

WARNING

Burst Hazard

High Pressure Unit

CAUTIONCAUTION

Burn Hazard

Do Not Touch An

Operating Motor