Catalina 310 User manual

Other Catalina Boat manuals

Catalina

Catalina 250 User manual

Catalina

Catalina Expo 12.5 User manual

Catalina

Catalina Jenny Lane User manual

Catalina

Catalina 350 User manual

Catalina

Catalina 22 1977 User manual

Catalina

Catalina C-22 1977 User manual

Catalina

Catalina Expo 14.2 User manual

Catalina

Catalina 34 MK II User manual

Catalina

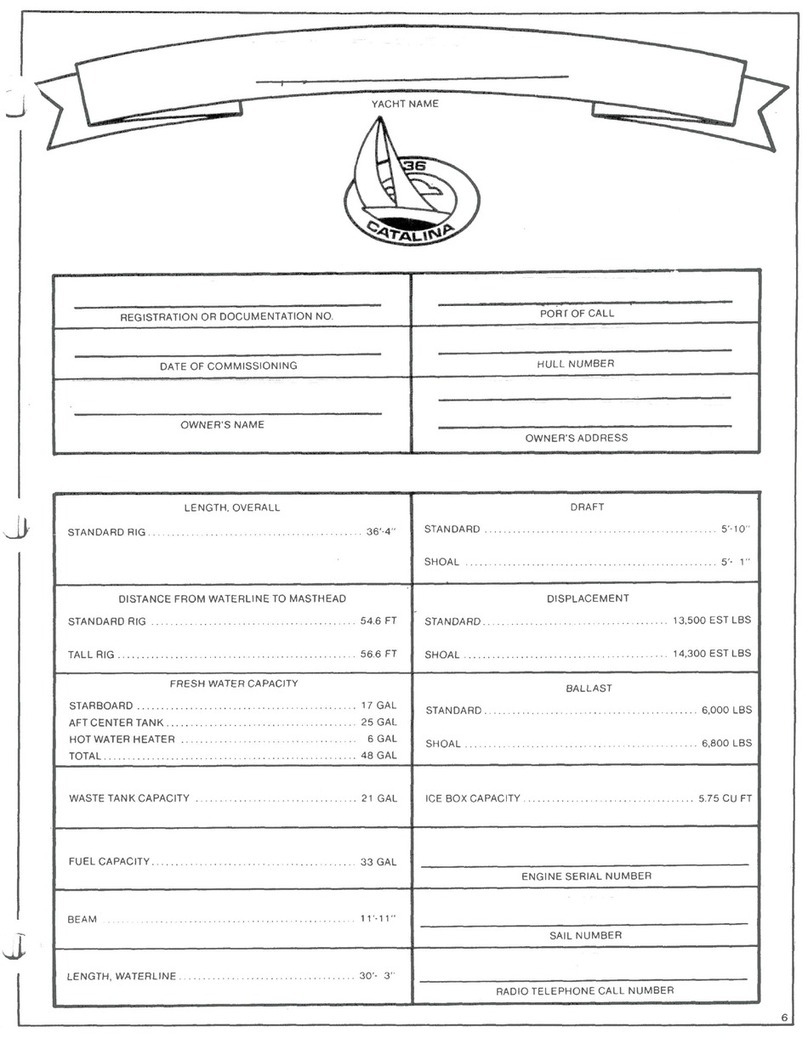

Catalina 36 User manual

Catalina

Catalina 250 User manual

Popular Boat manuals by other brands

Boston Whaler

Boston Whaler CONQUEST 345 owner's manual

Jeanneau

Jeanneau SUN ODYSSEY 41 DS owner's manual

Meridian

Meridian 490 Pilothouse owner's manual

Advanced Elements

Advanced Elements AdvancedFrame Expedition AE1009 owner's manual

Robo Marine Indonesia

Robo Marine Indonesia GEOMAR user manual

Swallow Boats

Swallow Boats BayRaider owner's manual