Page 4of 16

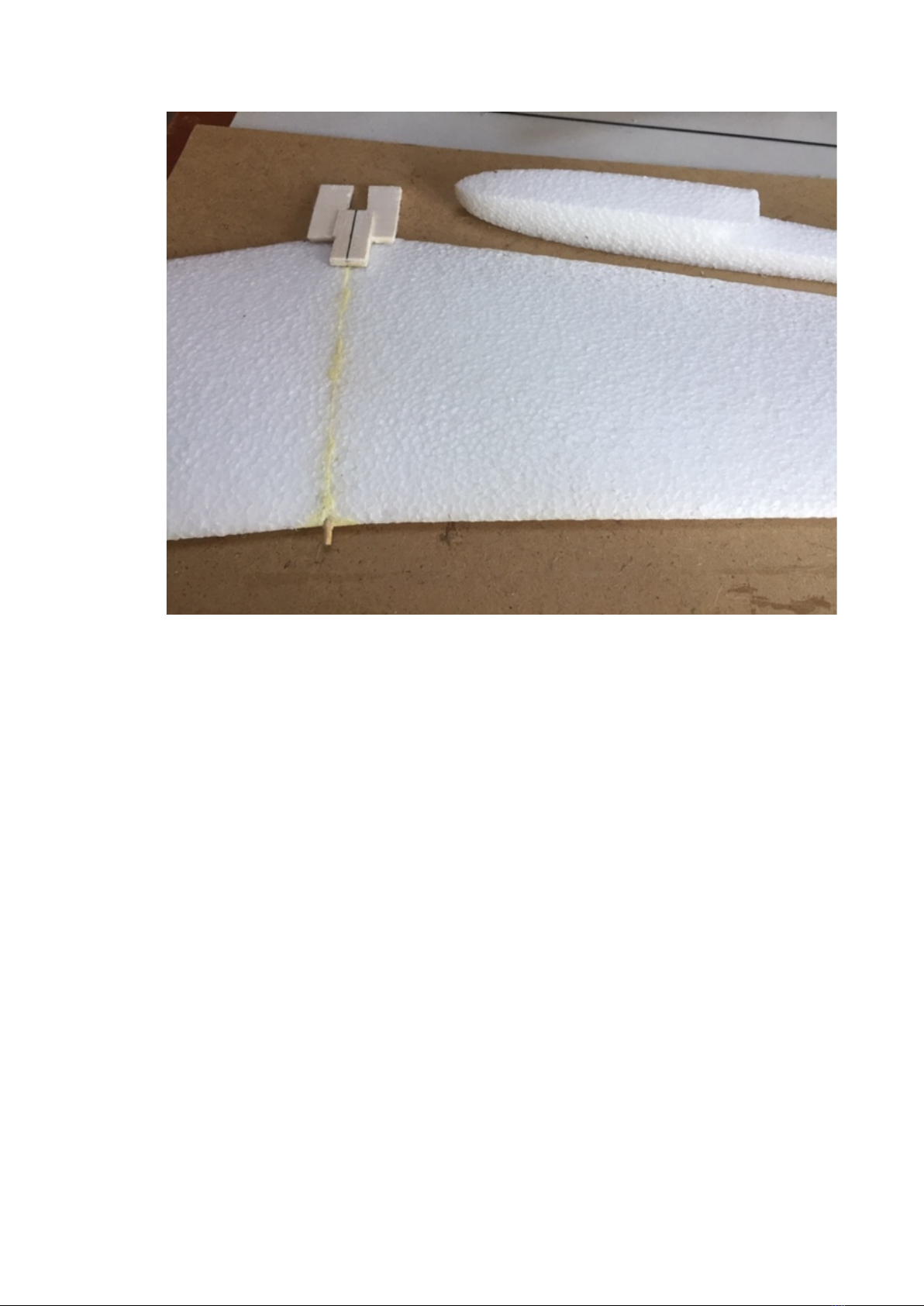

Join the 2 EPP wing halves together with the top of the wing on the table to end up with a

small dihedral on the lower wing surface. Make some puncher holes in each side of the EPP

wing root. Join the two wing halves together with tape on the upper surface and open up

the join from the bottom. Wet both surfaces. Apply Gorilla Glue and spread out with a small

stick forcing the glue into the puncher holes. Put the top surface of the wing on a flat surface

so the excess glue squeezes out and clean up the excess. Add some tape to the join and

weigh down so the wing top surface is flat.

Once set (2-3 hours) remove the tape and clean up the excess glue with a sharp knife blade

and then sandpaper smooth so there are no bumps. Don’t worry about any valleys, just the

peaks.

The 1.5mm carbon wing spars need a slot cut in the EPP wings. 40mm from the leading edge

at the root and 30mm at the tip looks about right and create a smooth bow curve. Tape the

spar in position and mark each side with a fine marker pen. I used a Dremel cut off wheel to

cut a slot no more than 2mm deep between the lines. Use a small stick to hold the wheel

shaft off the wing surface to keep a check on the cut depth.

Cut off the excess length of carbon rod which you can use for servo push rods. Roughen up

the surface off the carbon to take off the shine and help the glue stick.

Wet the spar slot with water, then add the Gorilla glue and spread with a small stick. Press in

the carbon wing spars and clean up the excess. The glue will try and push the carbon rods

out so they need to be weighed down as the glue dries. When cleaned up, cover the entire

length with tape. Put the wing upside down, top surface down and weigh down the length of

under side with 2 lengths. I used a couple of pieces of timber.

When dry remove the tape, cut off the excess glue that’s foamed up with a knife blade and

sand smooth. You should now have a very rigid wing.