| 5

SAFETY INFORMATION

SAFETY

INFORMATION

INSTALL ONLY APPROVED WORK SURFACES

This table system does not include a work surface (desktop). Work surface must be at least ¾" thick and weigh no

more than 5 lb. per square foot (For example, a 2'x6' desktop should weigh no more than 60 lb). Do not exceed a

maximum weight for the desktop of 75 lb. To prevent table from tipping or collapsing, make sure the desk frame

is not overloaded by the weight of tabletop and objects you plan to put on the table. If you are unsure, contact

customer service.

KEEP AWAY FROM CHILDREN

This table system is not designed for use in homes or other areas accessible by small children.

For indoor commercial ofce use only.

BE CAREFUL WHEN ADJUSTING DESK HEIGHT

Body parts and property can be caught between the

moving work surface and an immobile obstacle (such as

shelves, furniture, window sills, or walls). Keep at least

one inch of clearance around desk and make sure nothing

is in table’s path for its entire range of motion.

Before raising or lowering:

• Check surroundings on all sides of desk are clear

• Make sure corded objects will not be pulled off table

or cause other objects to fall

• Make sure desk power cord moves freely

as desk moves up and down

IMPORTANT SAFETY INSTRUCTIONS Save these instructions.

DANGER

To reduce the risk of electric shock:

Always unplug this furnishing from the electrical outlet before cleaning.

WARNING:

To reduce the risk of death, serious injury, or property damage, read and

follow this safety information and the provided instructions when assembling this product.

Do not change or replace components and accessories provided by OMT-Veyhl.

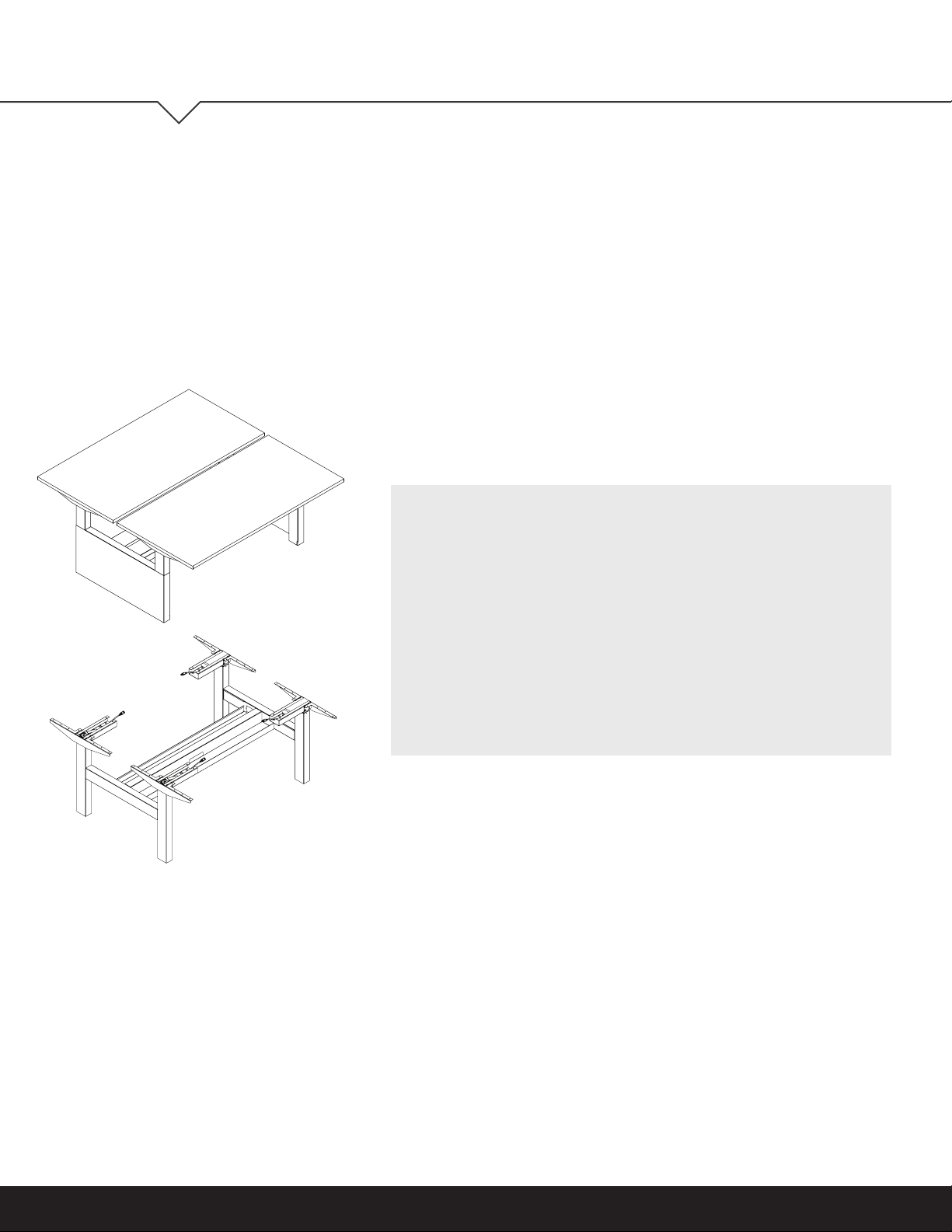

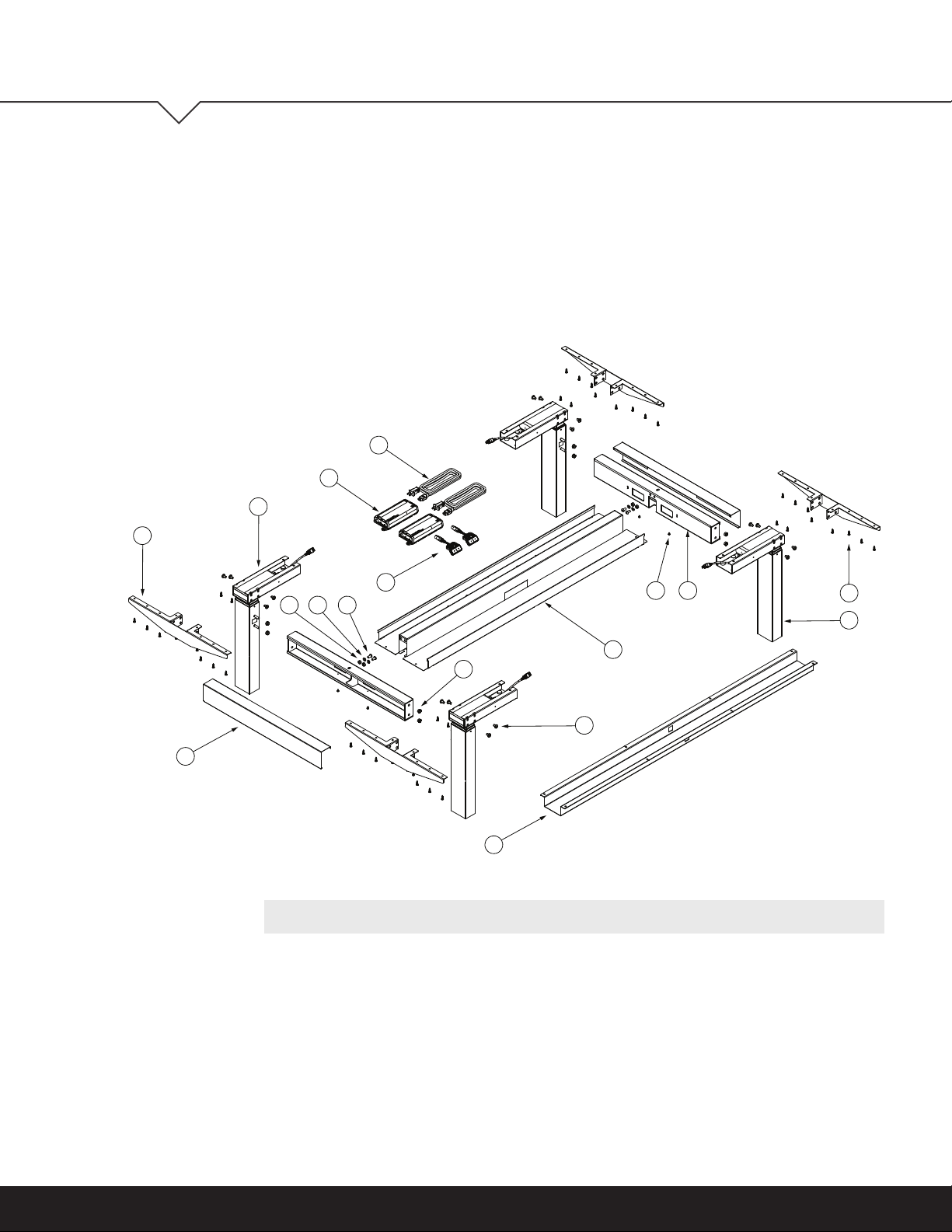

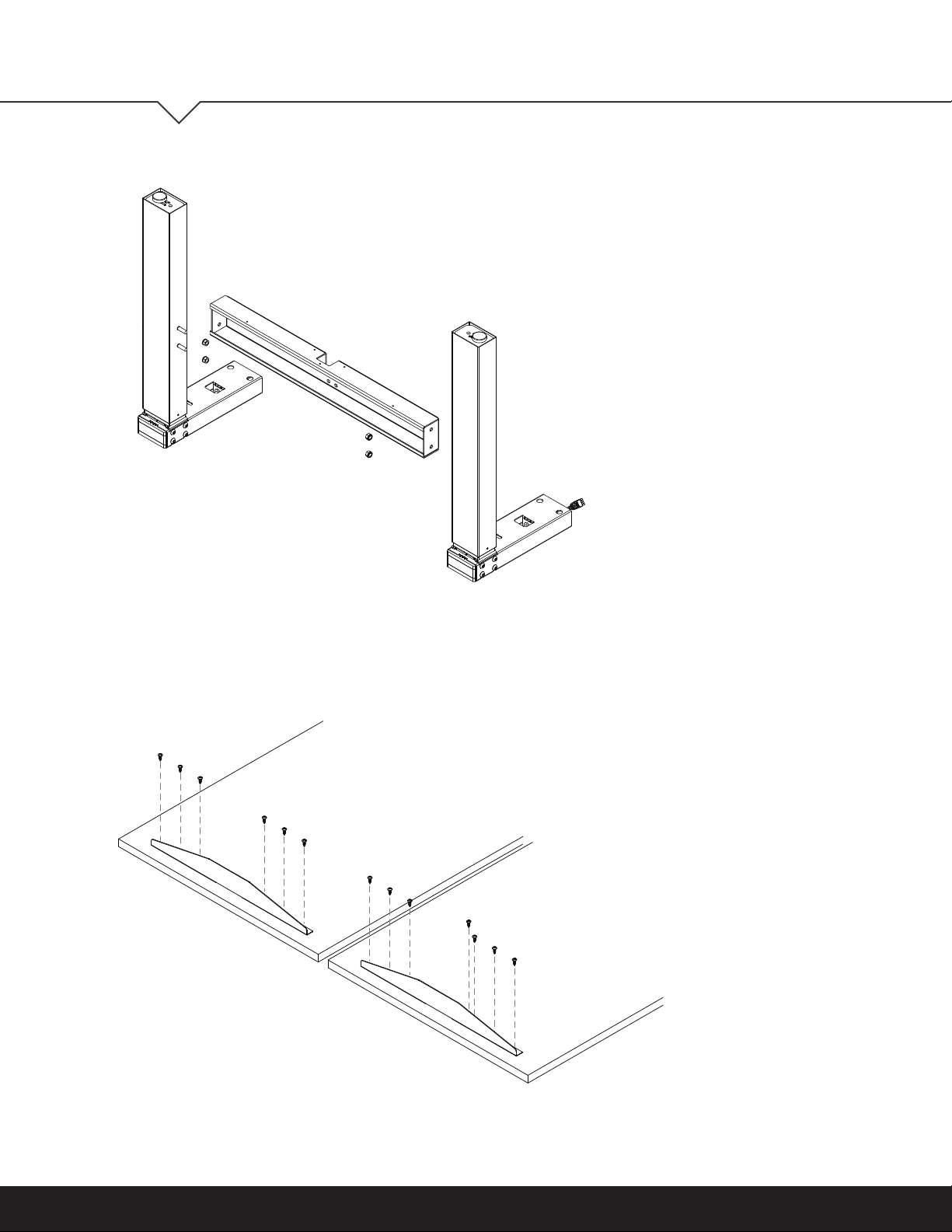

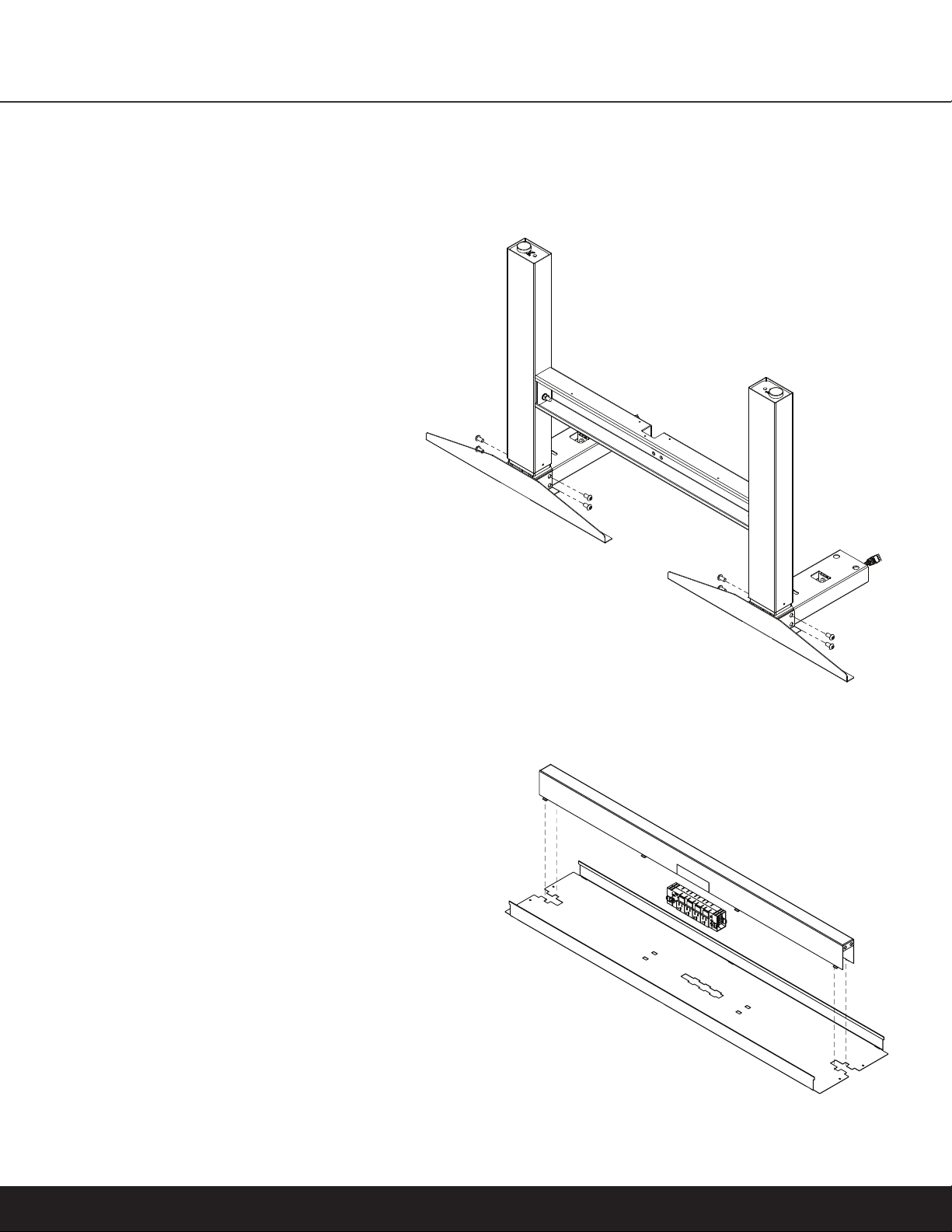

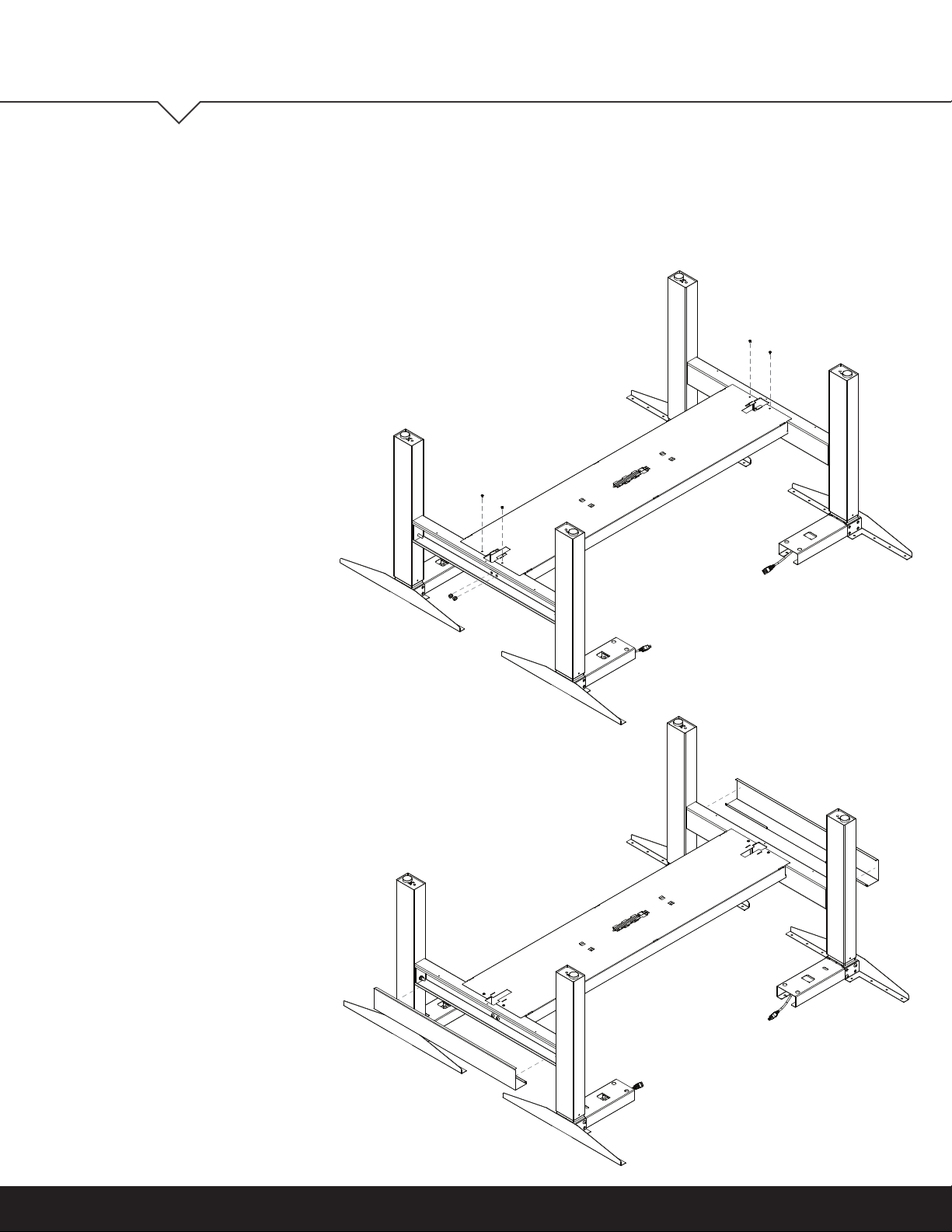

PARTS DIAGRAM