1.Introduction

The main board of “Chitu” carries high speed microchip with 32 bit,

adopting self-developed firmware that enjoys the advantages of open source

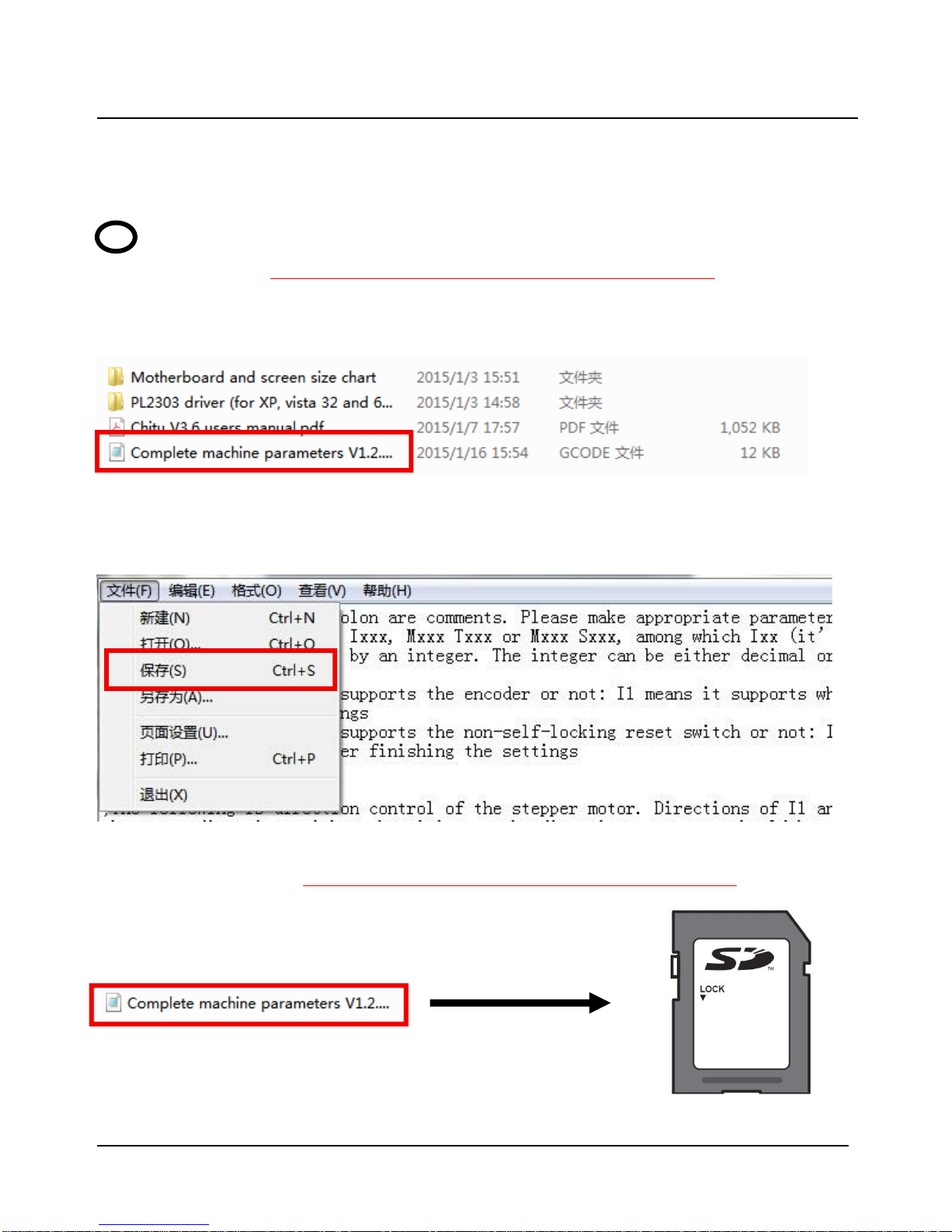

firmware. Besides, it also carries out repeated optimization, employing SD

file configuration mode which will bring about convenient and quick

renewal.

“Chitu” mainboard matches color touch screen, enjoying simple interface

and high sensitivity. The firmware has experienced arc optimization, PID

temperature stability optimization, which is in favor of breakpoint saving

and shutdown automatically after printing. Currently, we can provide the

services of customized operation interface of the screen, customized APP on

the mobile phone, and customized software on PC, offering you a platform

to show your company. This system is bilingual and can be switched

between Chinese and English by one button. CBD-Tech can provide the

services for different languages.

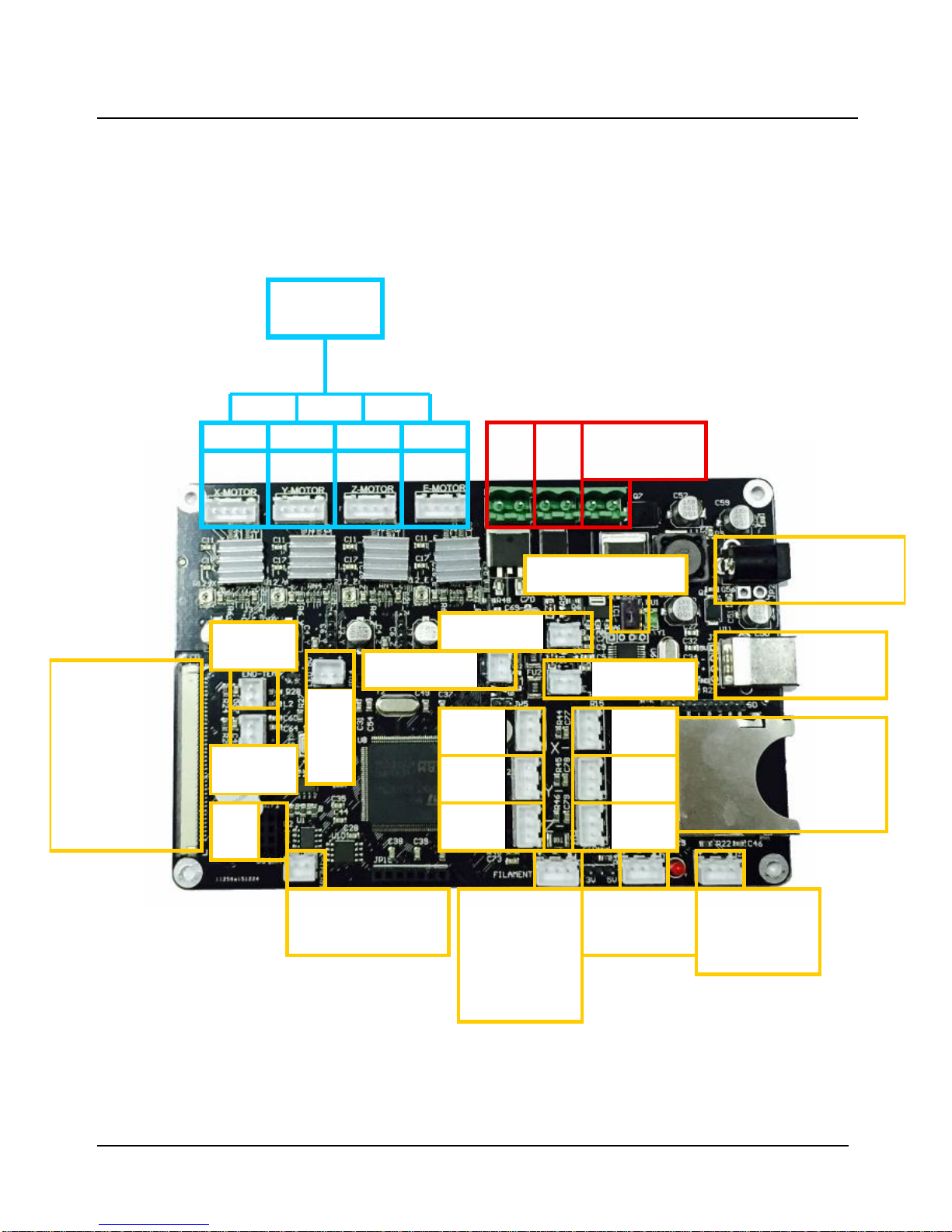

1.1 Parameters of Mainboard

External Dimension:150*100mm

Microprocessor : STM32

Input Voltage : 12V~24V 10~15A

Power Interface: Switching power supply or adapter

Motor Driver: Allegro A4988 (1/16 microstepping)

ChiTu V3.6 can be externally connected motor drive

Motor Driven Interface: Single head motherboard has four motor interface

Double head motherboard has five motor interface

Temperature Sensor Interface: 3 paths of 100K NTC (thermistor)

2 paths of MAX6675(thermocouple)

Color Touch Screen: 2.8 or 3.5 inches of TFT

Upgraded Firmware supporting SD card (supports 8G<= FAT 16 and FAT32)

Square USB that is convenient in pull and plug,Communication Baud Rate is 115200

File Format Supported: G-code

Machine Structure Supported: XYZ type, Ultimaker type, Hbot type, Delta,Kossel type.

Recommendation of Software: Cura/Repetier-host/Makerware/Simplify3d

Expandable modules: WIFI module, power module( continue to print after power off), large

motor drive, SD card module, USB drive module