2/29

CONTENTS

1. Introduction....................................................................................................................3

2. Safety instructions..........................................................................................................4

2.1 Use of machine.................................................................................................................. 4

2.2 Ventilation......................................................................................................................... 4

2.3 Risks during use................................................................................................................ 4

2.4 Moving the machine.......................................................................................................... 4

3. Technical Specifications.................................................................................................6

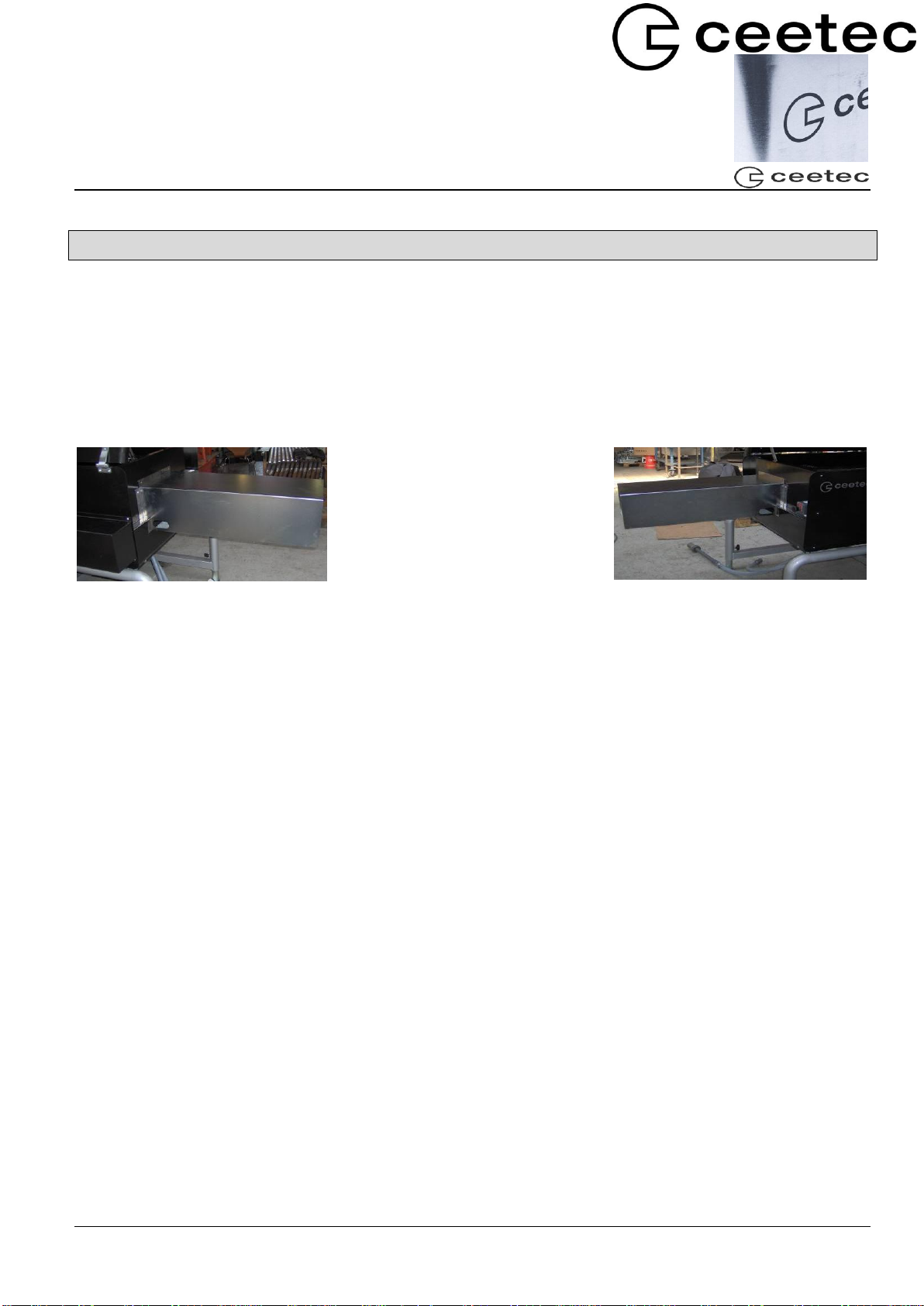

4. Preparing the machine for use ......................................................................................7

5. Adjusting the machine ................................................................................................... 8

5.1 The lid on the machine is opened...................................................................................... 8

5.2 Feeder guide and the guide in the middle of the machine................................................. 8

5.3 Sanding heads, brushes and screens/shields...................................................................... 8

5.4 Forward drive.................................................................................................................... 9

5.5 Test run and flow rate ....................................................................................................... 9

5.6 Opening the lid................................................................................................................ 10

5.7 Reversing of circulation direction on the sanding heads................................................. 10

6. Cleaning......................................................................................................................... 11

7. Maintenance.................................................................................................................. 12

7.1 V-belts, chains and toothed belts. ................................................................................... 12

7.2 Greasing.......................................................................................................................... 12

8. Replacing spare parts................................................................................................... 13

8.1 Motor v-belt – intermediate shaft I................................................................................. 13

8.2 V-belt – vertical brushes.................................................................................................13

8.3 V-belt for forward drive engine – intermediate shaft I ................................................... 14

8.4 Toothed belt for horizontal brushes (9015-20510, picture C)......................................... 14

8.5 Toothed belt for forward drive (9015-20525, picture C)................................................ 14

8.6 Changing of sanding strips (with use of Flextrim sanding heads).................................. 14

9. Trouble shooting........................................................................................................... 15

10. Spare parts list.............................................................................................................. 16

11. Accessories .................................................................................................................... 18

12. Production address....................................................................................................... 18

13. Spare-parts overview ...................................................................................................19