Page 4 | 1-855-235-5271 CX 040418

NOTE: CellarCool units are manufactured in the USA and tested prior to shipment.

Please leave the CellarCool unit in its original box until you are ready for installation. This will allow you to move the product

safely without damaging it. When you are ready to remove the product from the box, refer to the installation instructions.

TIP: Save your box and all packaging materials. They provide the only safe means of transporting/shipping the unit.

cx3300 and cx4400

Accessory kit #1:

•(1) CellarCool CX Series owner’s

manual

•(2) Mounting flanges

•(2) Magnetic deflectors for airflow

control

•(18) Anti-microbial pan tabs

•(1) Drain line brush

Accessory kit #2:

•(8) #6 x 1¾" hex washer head screws

• (6) ½" pan-head screws

•(1) ½" ID plastic tubing (10 feet)

•(2) Pieces of insulation foam (20")

•(2) Pieces of insulation foam (17")

RECEIVING AND INSPECTING THE UNIT

Upon receiving your CellarCool unit:

•Lift only at the designated hand-hold locations on the shipping container, or fully support the unit from underneath. A

shipment may include one or more boxes containing accessories.

•Inspect the packaging for any obvious signs of damage or mishandling before opening the container.

•Note any discrepancies or visual damage on the bill of lading before signing.

•Place the box containing the CellarCool unit on a tabletop to prepare it for testing prior to installation.

•Sit unit upright for 24 hours.

•Review the packing slip to verify the package’s contents.

•Check the model number to ensure it is correct.

•Check that all factory options ordered are listed.

•Check the box for the following:

Electrical Outlet

Power surges and spikes can damage sensitive electrical equipment. CellarCool recommends plugging the unit into a surge

protector or power conditioner in order to protect your system. As outlined in our terms and conditions, power surges and spikes

are not covered under warranty.

Do not use a GFI (ground fault interrupter) with this product.

Testing Unit

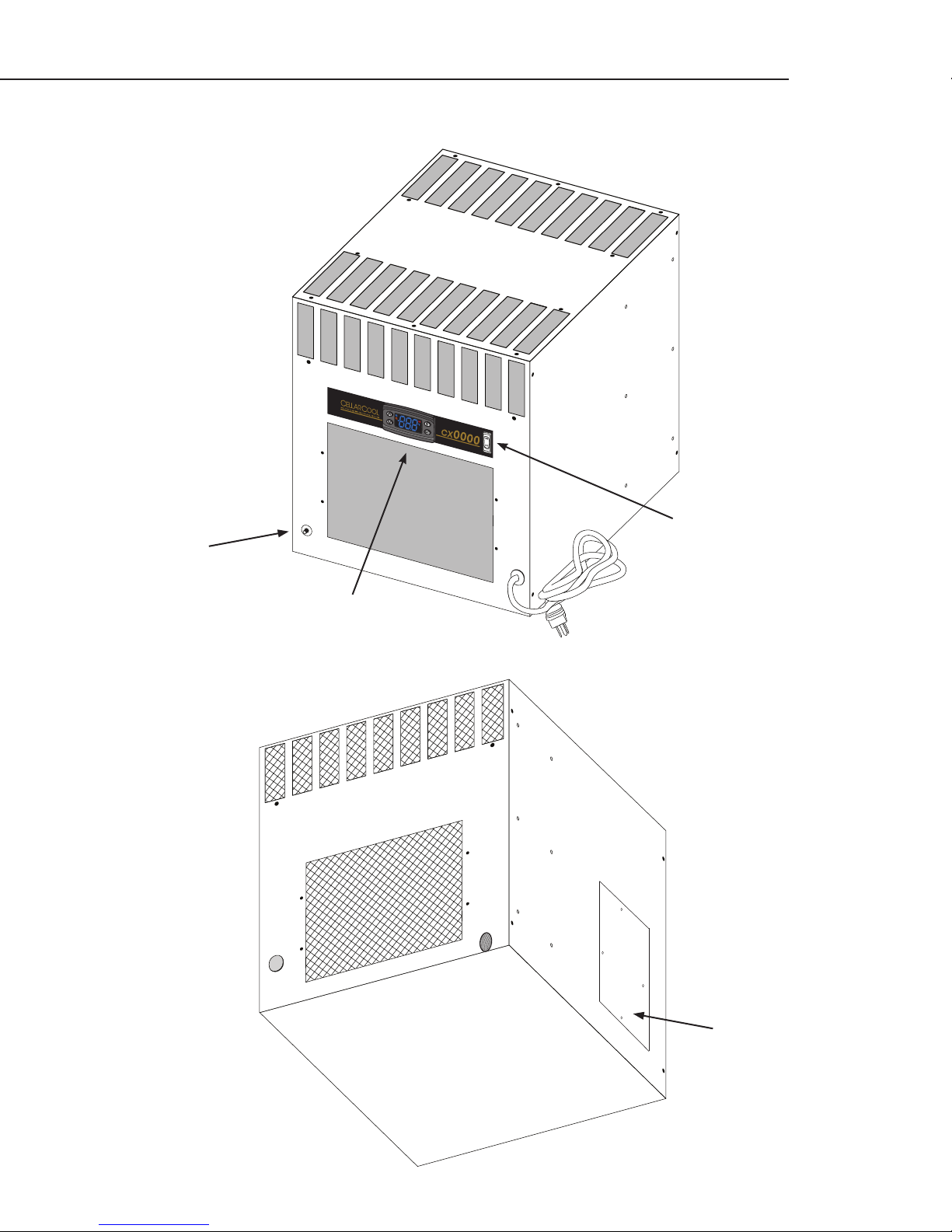

Carefully remove your CellarCool unit from the box. Place the CellarCool system on a tabletop to prepare it for installation and

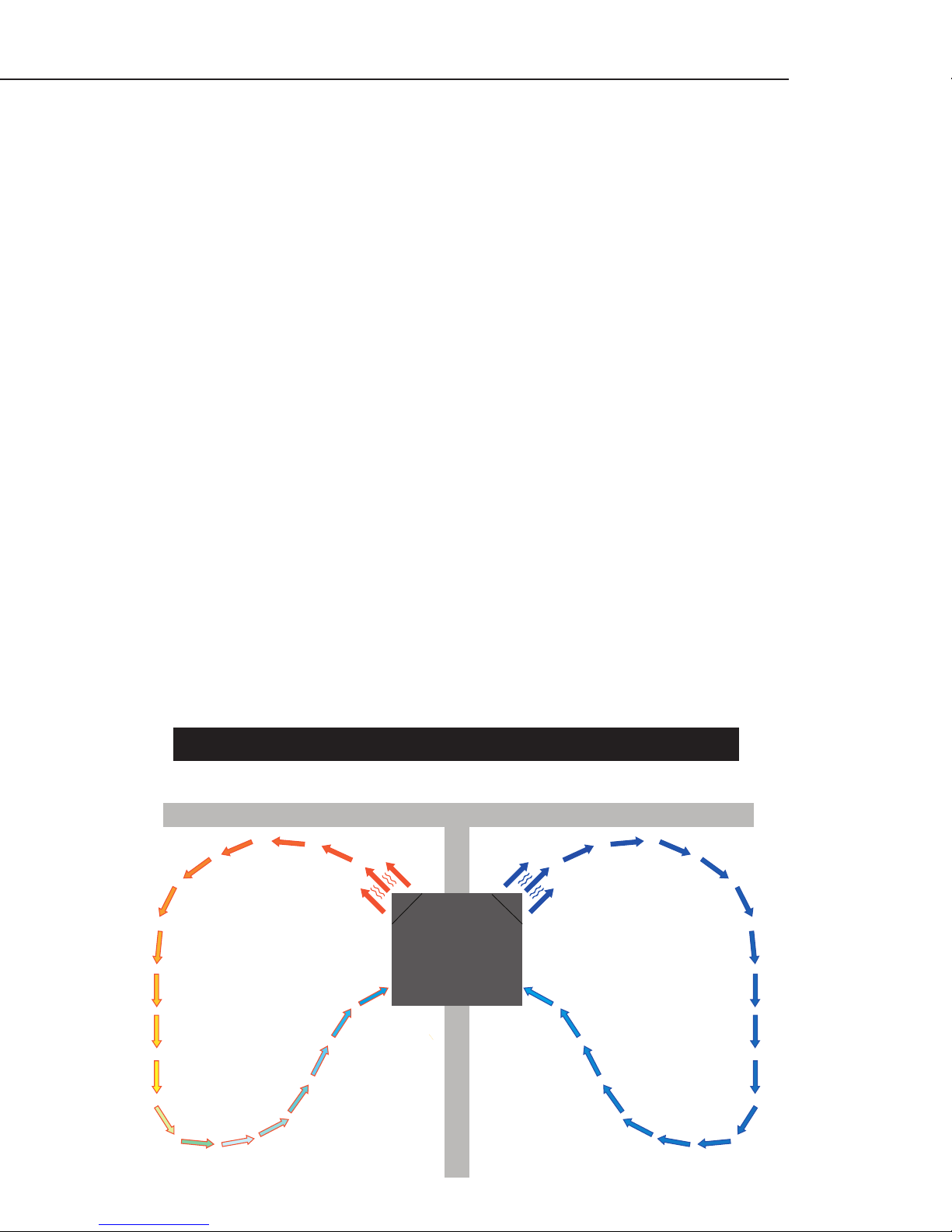

testing. Plug system into a live electrical outlet and turn it on. The system may take up to 10 to 15 minutes before all four fans are

running, cold air is coming out on the cellar side, and hot air is coming out on the exhaust side. Once the operation has been tested,

turn the unit o and unplug it from the electrical outlet.*

*NOTE: If the system does not seem to be fully functional after 15 minutes, please refer to the Troubleshooting Guide on page 19.

Units weigh 55-101 pounds and are cumbersome for one person to carry. We recommend that you get someone else to help you

during the installation process. NEVER LAY UNIT ON ITS SIDE.

cx8800

Accessory kit #1:

•(1) CellarCool CX Series owner’s

manual

•(2) Mounting flanges

•(2) Magnetic deflectors for airflow

control

•(18) Anti-microbial pan tabs

•(1) Drain line brush

Accessory kit #2:

•(8) #6 x 1¾" hex washer head screws

• (6) ½" pan-head screws

•(1) ½" ID plastic tubing (10 feet)

•(2) Pieces of insulation foam (20")

•(2) Pieces of insulation foam (17")

cx2200

Accessory kit #1:

•(1) CellarCool CX Series owner’s

manual

•(2) Mounting flanges

•(2) Magnetic deflectors for airflow

control

•(18) Anti-microbial pan tabs

•(1) Drain line brush

Accessory kit #2:

•(8) #6 x 1¾" hex washer head screws

• (6) ½" pan-head screws

•(1) ½" ID plastic tubing (10 feet)

•(2) Pieces of insulation foam (20")

•(2) Pieces of insulation foam (17")