2

INDEX page

1. General characteristics ....................................................................................................................................................... 4

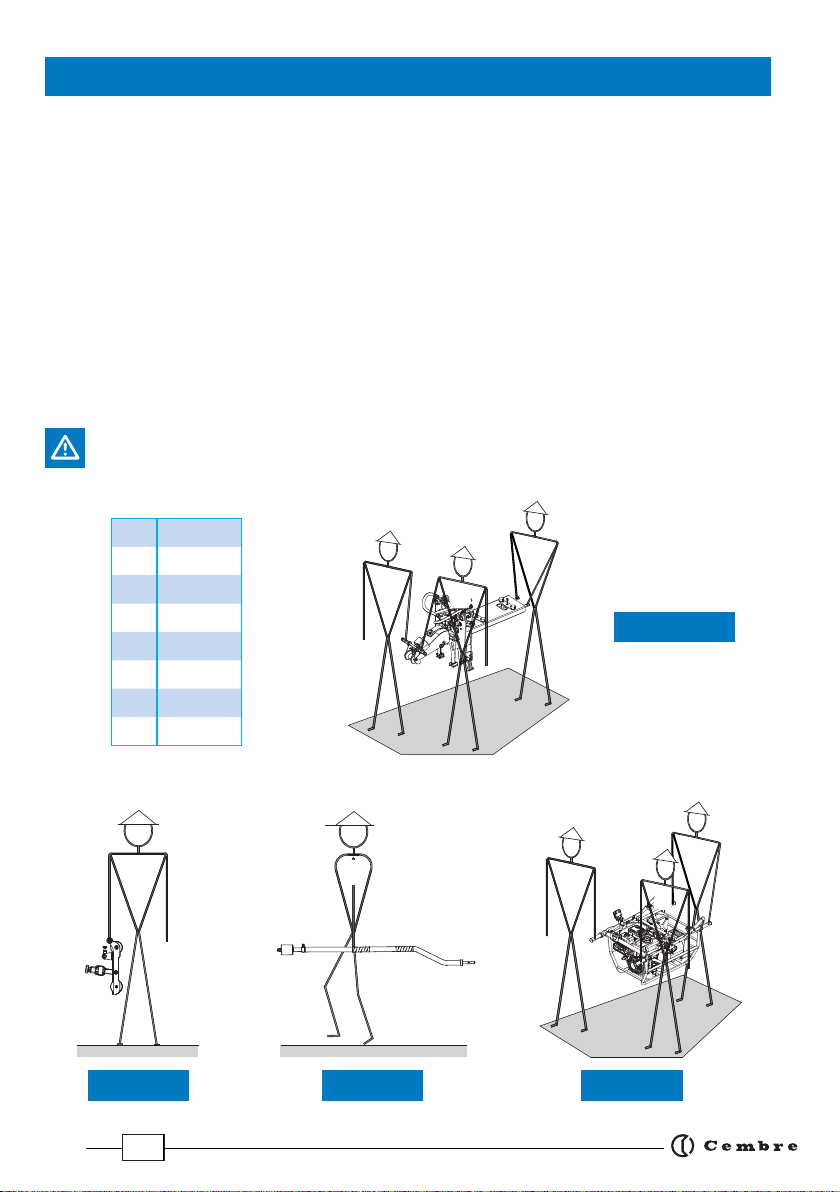

2. Unpacking .............................................................................................................................................................................. 5

2.1 Transporting the machine ................................................................................................................................................ 5

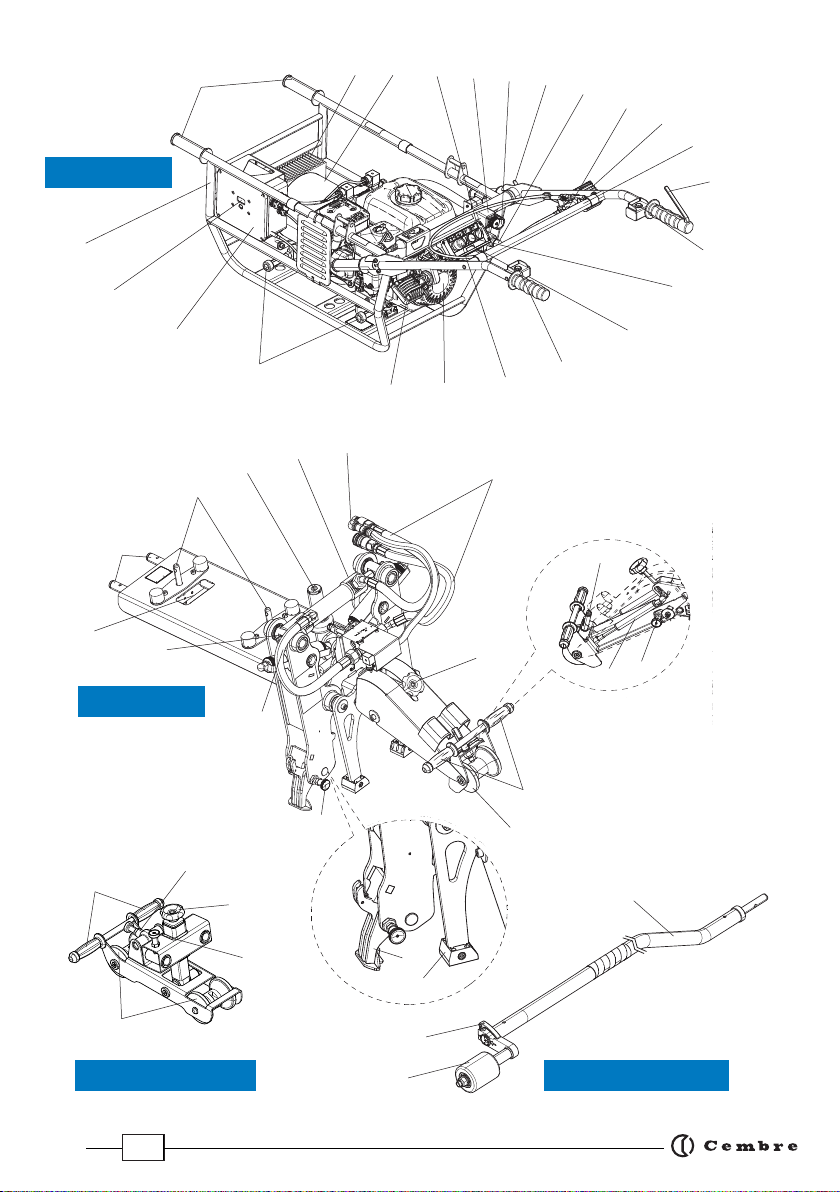

3. Description of the machine ............................................................................................................................................. 6

4. Instructions for use ............................................................................................................................................................. 8

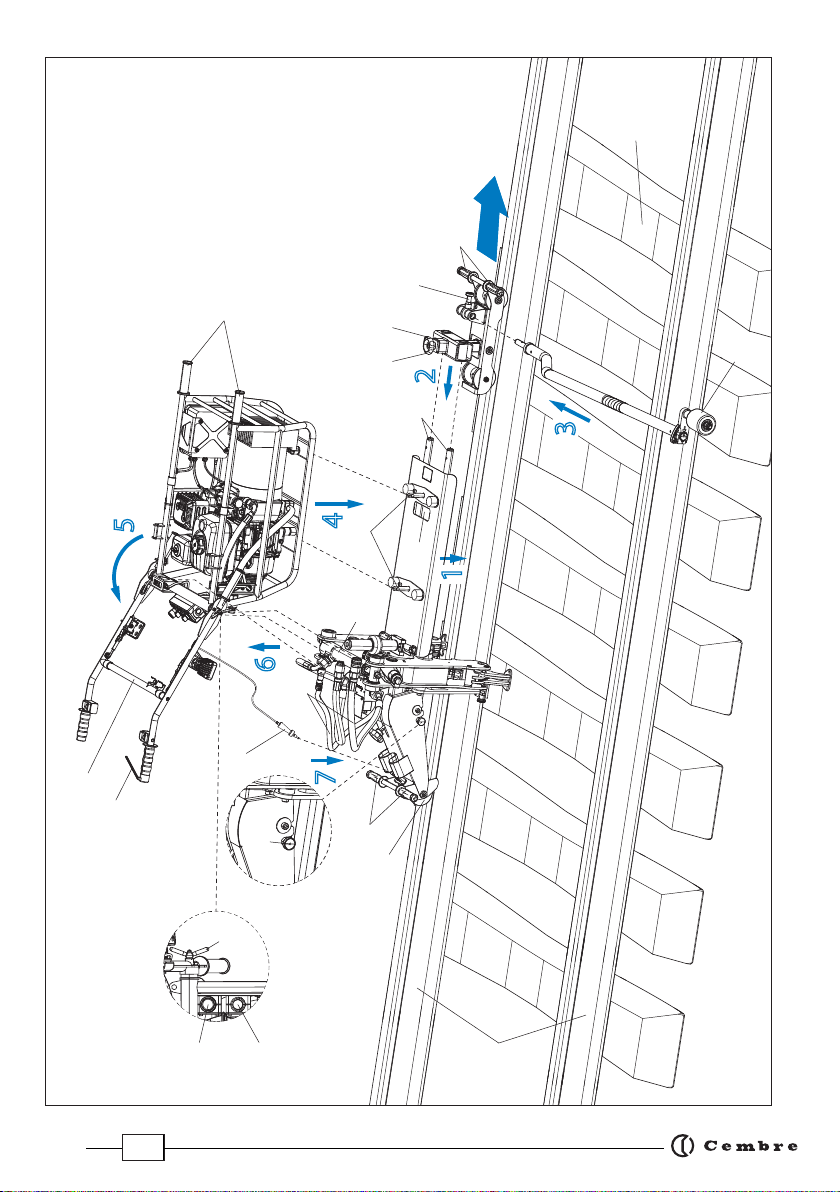

4.1 Assembling the machine ................................................................................................................................................. 8

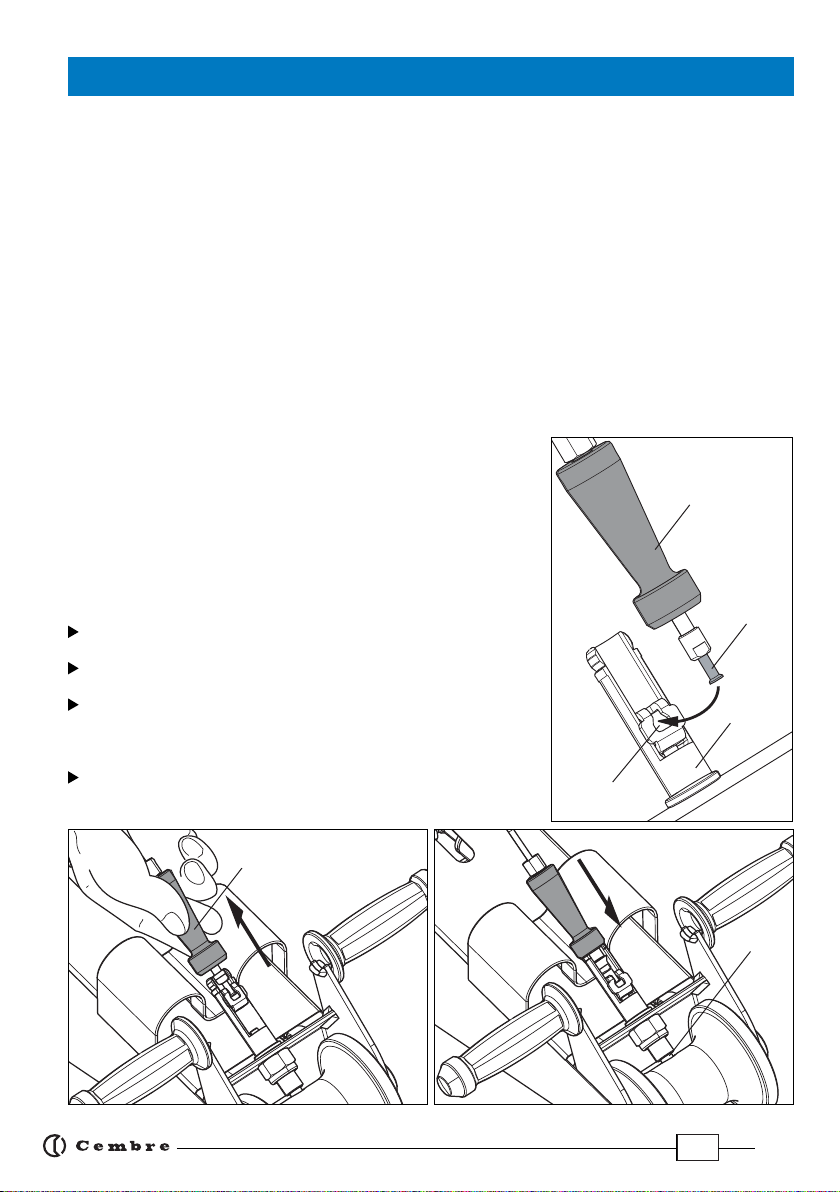

4.1.1 Braking device ...................................................................................................................................................................... 8

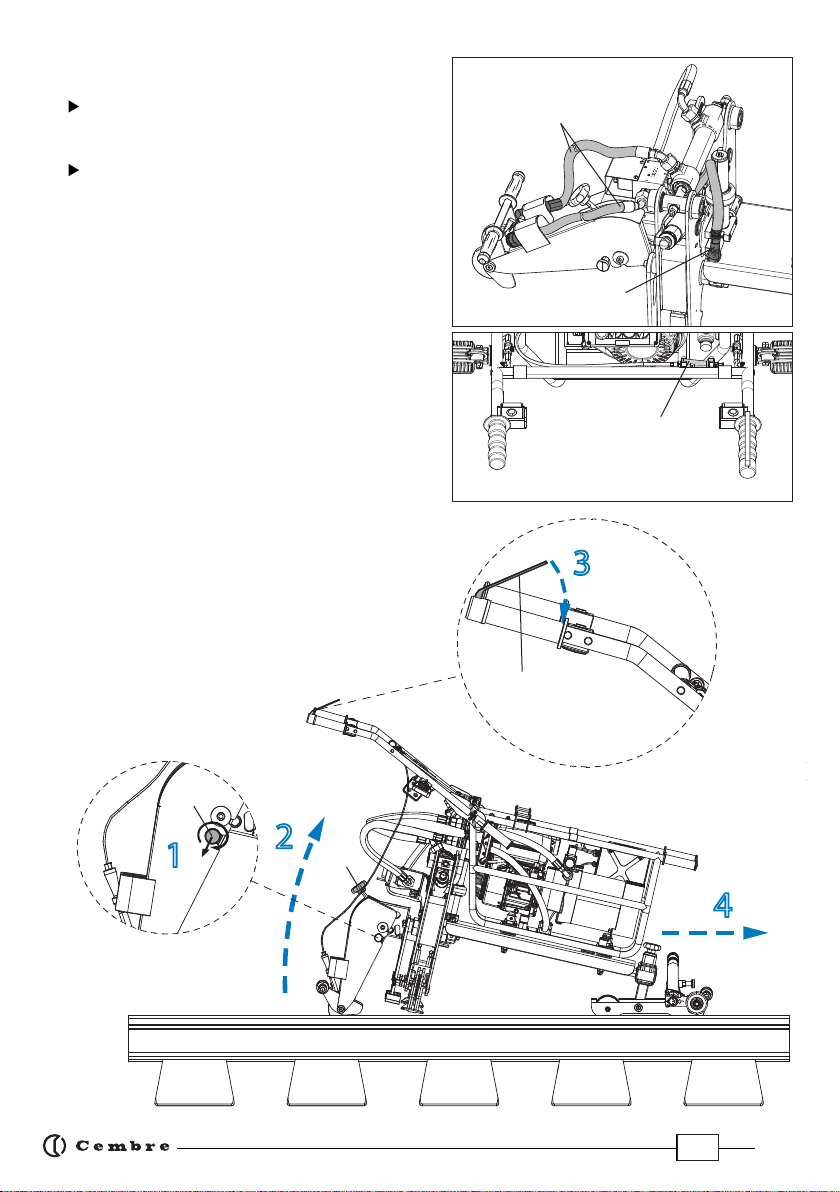

4.2 Disassembling the machine ........................................................................................................................................... 10

4.3 Moving the machine .......................................................................................................................................................... 10

4.4 Controls ................................................................................................................................................................................... 11

4.5 Description of the Pandrol Fast clip .............................................................................................................................. 12

4.6 Description of the Pandrol FE clip ................................................................................................................................. 13

4.7 Description of the Pandrol FCX clip .............................................................................................................................. 14

4.8 Preliminary machine adjustments ................................................................................................................................ 15

4.8.1 Adjusting the height of the front of the machine .................................................................................................... 15

4.8.2 Stable support of both insertion teeth ........................................................................................................................ 15

4.8.3 Adjusting the piston for lifting sleepers ...................................................................................................................... 16

4.8.4 Adjusting the clamp position .......................................................................................................................................... 16

4.9 Operation ................................................................................................................................................................................17

4.9.1 Inserting clips ........................................................................................................................................................................ 17

4.9.2 Extracting clips ..................................................................................................................................................................... 18

4.9.3 Adjusting the contrast foot for extraction .................................................................................................................. 18

5. Adjusting the piston stroke .............................................................................................................................................. 19

5.1 Adjusting the piston stroke for clip insertion ............................................................................................................ 19

5.2 Adjusting the piston stroke for clip extraction ......................................................................................................... 20

5.2.1 Parking position ................................................................................................................................................................... 20

5.2.2 Insulator change position ................................................................................................................................................ 20

6. Display ..................................................................................................................................................................................... 21

6.1 Information screens ............................................................................................................................................................ 21

6.2 Warnings ................................................................................................................................................................................. 21

6.3 Errors ........................................................................................................................................................................................ 22

7. Starting the engine ............................................................................................................................................................. 23

8. Maintenance ......................................................................................................................................................................... 24

8.1 Routine maintenance of the machine ......................................................................................................................... 24

8.1.1 Maintenance of braking device ...................................................................................................................................... 24

8.1.2 Maintenance of clamp unit .............................................................................................................................................. 25

8.1.3 Topping up the oil in the hydraulic pump .................................................................................................................. 26

8.1.4 Replacing the hydraulic pump oil lter ......................................................................................................................... 26

8.1.5 Adjusting the work lights ................................................................................................................................................. 26

8.1.6 Changing the gas springs ................................................................................................................................................. 27

8.2 Routine maintenance of the engine ............................................................................................................................. 27

8.3 Long periods of inactivity ................................................................................................................................................. 27

9. Return to Cembre for overhaul .................................................................................................................................... 30