NOTICE: To receive any expressed or implied warranty, the tool must be repaired by an authorized Service Center.

The 3 in. (77 mm) Ergolite Random Orbital Sander Service Instructions section provided is for use after completion

of the warranty period.

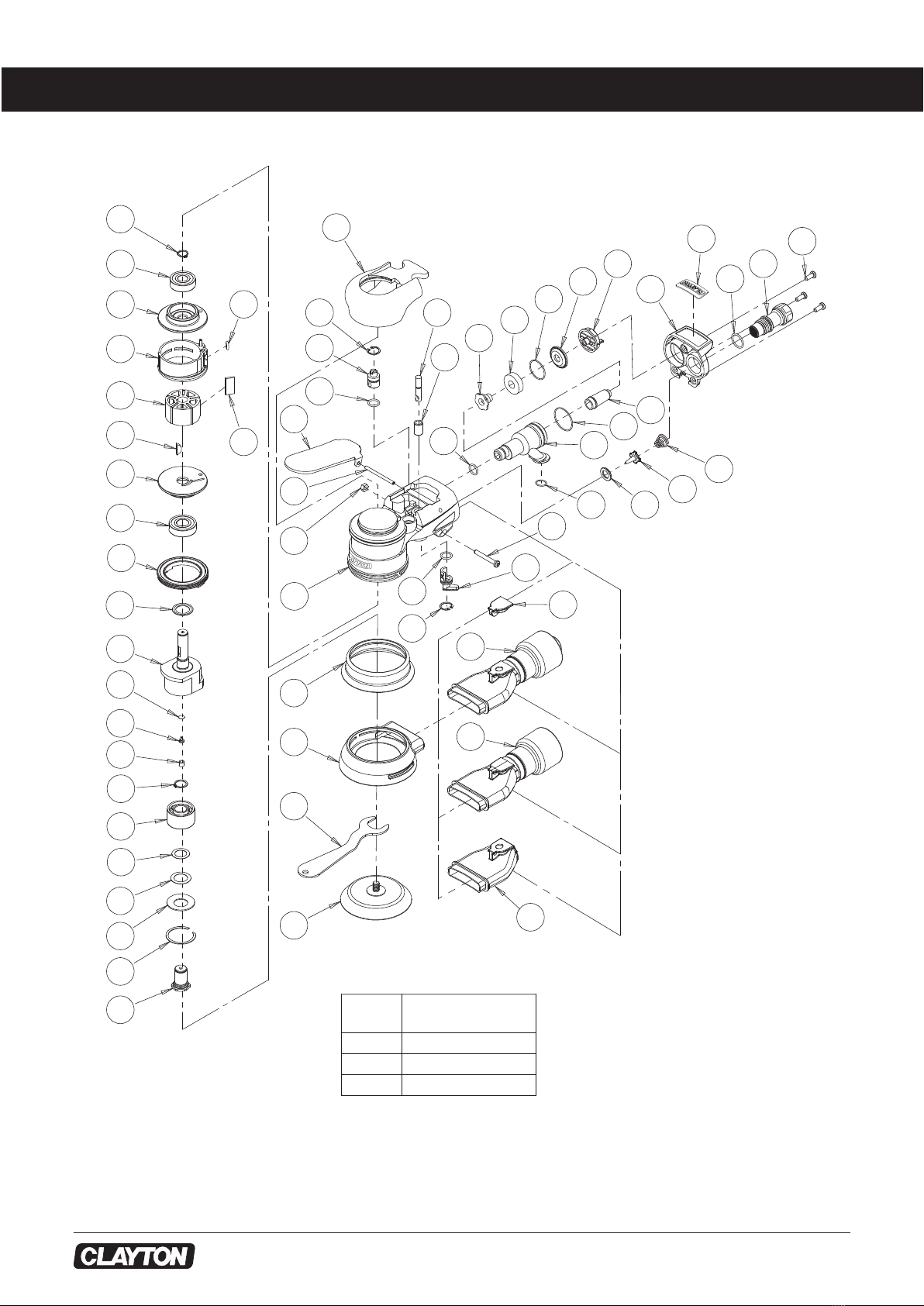

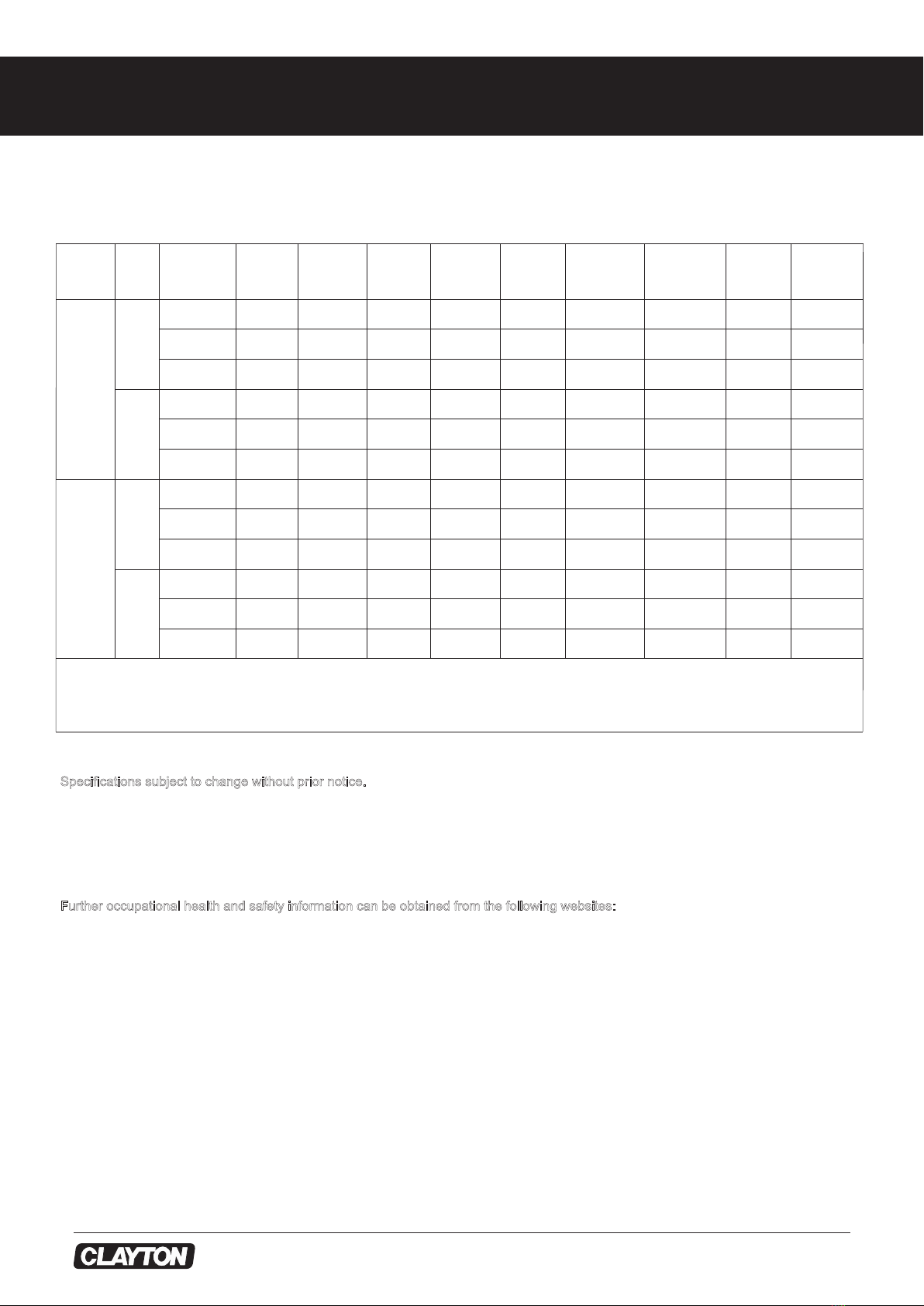

12,000 RPM 3 in. (77 mm) Ergolite ROS Service Instructions

Motor Disassembly:

1. Lightly secure the tool in a vise using the T-7 Service Col-

lar or padded jaws. Use a 17 mm Pad Wrench to secure

the Spindle and spin the Pad counter clock-wise off the

spindle.

2. Remove the Lock Ring with the T-6 Motor Lock Ring

Wrench/Spindle Puller Tool. The motor assembly can now

be lifted out of the Housing. Remove the O-Ring from the

Lock Ring.

3. Secure the motor assembly by clamping the Shaft

Balancer in a padded jaw vise and remove the Retaining

Ring from the end of the Shaft Balancer and the O-ring

from the Cylinder.

4. Remove the Rear Endplate. This may require support-

ing the Rear Endplate with a bearing separator. Use a

light press force to push the Shaft Balancer through the

Bearing. Then remove the Cylinder, Vanes and the Rotor.

Remove the Key from the Shaft Balancer. Support the

Front Endplate with a bearing separator and use a light

press force to push the Shaft Balancer through the bear-

ing. It may be necessary to remove the Bearing with a

bearing separator if it came out of the Front Endplate and

stuck to the shaft of the Shaft Balancer.

5. Remove the Bearing(s) from the Endplates by using

the T-8 Endplate Bearing Removal Tool to press out the

Bearings.

Shaft Balancer and Spindle Disassembly:

1. Grip the shaft end of the Shaft Balancer in a padded vise.

With a thin screwdriver pick out the slotted end of the

Retaining Ring and peel out.

2. Screw the female end of the T-11 5/16-24 to 1/4-20

Adapter into the male end of the Service Wrench. Screw

the Service Wrench assembly into the Spindle Assembly

until hand tight. Apply a gentle heat from a propane torch

or hot air gun to the large end of the Shaft Balancer until

it is about 212° F (100° C) to soften the adhesive. Do not

over heat. Remove the Spindle Assembly by using the

Slider to give sharp outward blows to the Spindle. Allow

the parts to cool so they are safe to handle.

3. Remove the Retaining Ring from the Spindle Assembly.

Use a small Bearing Separator to remove the Bearing,

Shim, Bearing, Shim and the Washer from the Spindle

Assembly.

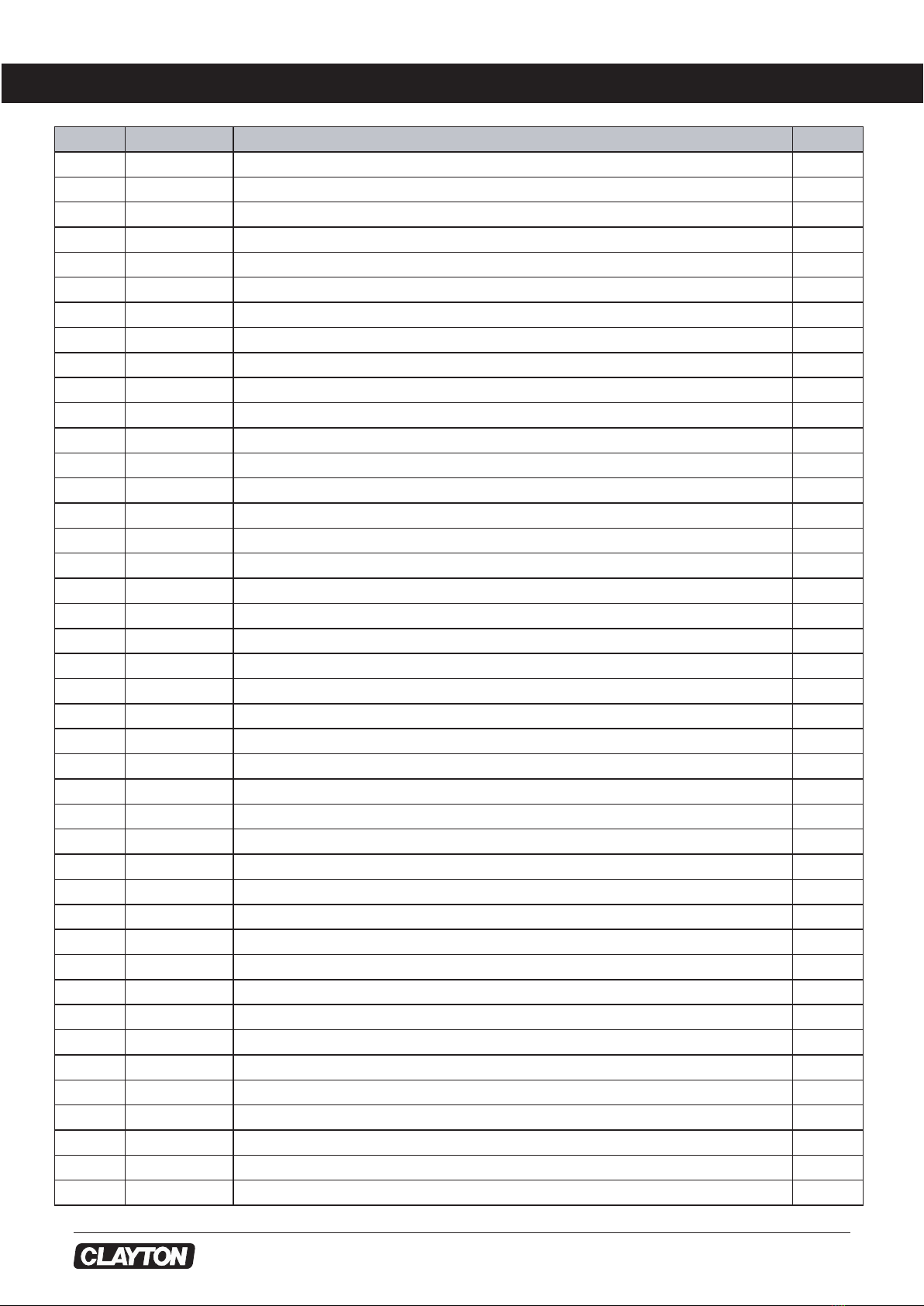

ASSEMBLY INSTRUCTIONS

NOTE: All assembly must be done with clean dry parts and

all bearings are to be pressed in place by the correct tools

and procedures as outlined by the bearing manufacturers.

Housing Assembly:

1. Install Throttle Lever into Housing with Spring Pin.

2. Lightly grease the O-Ring and place it on the Speed Con-

trol. Install the Valve Stem and O-ring (cleaned and lightly

greased) and insert the Speed Control into Housing in the

midway position. Install Retaining Ring.

CAUTION: Make sure the Retaining Ring is completely

snapped into groove in the Housing.

3. Install the Valve Seat, Valve and the Spring. Coat the

threads of the Inlet Bushing Assembly with 1 or 2 drops

of Loctite™ 222 or equivalent non-permanent pipe thread

sealant. Screw the Inlet Bushing Assembly into the inlet

port on the Housing. Torque to 60 in/lbs (6.77 Nm.)

Spindle Bearings, and Shaft Balancer

Assembly:

1. Place the T-5A Spindle Bearing Pressing Tool Base onto

with the spindle pocket facing upward. Place the Spindle

into the spindle pocket with the shaft facing upwards. See

Figures 1 and 2.

2. Place theWasher on the Spindle shaft with the curve of

the Washer facing out so that the outside diameter of the

Washer will contact the outer diameter of the Bearing

(one seal). Lay the Shim on the shoulder of the Spindle.

Place the Bearing (one seal) on the Spindle with the seal

side toward the Washer. NOTE: Make sure that both the

inner and outer races of the Bearings are supported by

the Bearing Press Tool when pressing them into place.

Press the Bearing onto the shoulder of Spindle using

the T-5B Spindle Bearing Pressing Tool Top as shown in

Figure 2.

3. Place the Shim over the Spindle shaft and onto the face

of the Bearing making sure it is on center. Press the

(no seals/shields) Bearing down using the T-5A Spindle

Bearing Pressing Tool Top, being careful to make sure

the Shim is still centered on the vertical axis of the

Spindle shaft and Bearing. See Figure 3. NOTE: When

the Spindle Assembly is done correctly, the Bearings will

rotate freely but not loosely and the Shim can be moved

but will not slide or move by gravity.

4. Secure the Retaining Ring onto the Spindle Assembly

making sure it is completely snapped into the groove. Set

the Spindle Assembly aside.

5. Take the Filter and center it on the small bore that

Valve into the bore so it is oriented correctly, then press

of the bearing bore.

6. Apply a pin head size drop of #271 Loctite® or equivalent

to the outside diameter of each of the bearings on the

Spindle Assembly. Spread the drop of bearing locker

around both bearings until distributed evenly. CAUTION:

Only a very small amount of bearing locker is needed

to prevent rotation of the bearing OD. Any excess will

into the bore of the Shaft Balancer and secure with the

Retaining Ring. CAUTION: Make sure that the Retaining

Ring is completely snapped into the groove in the Shaft

Balancer. Allow the adhesive to cure.

DISASSEMBLY INSTRUCTIONS

Changing Grips:

1. The Grip has two “tabs” that wrap around the body of the

sander under the inlet and exhaust. With a small screwdriver

pick out one of the “tabs” of the Grip, and then continue to go

underneath the grip with the screwdriver and pry the Grip off

the sander. To install a new Grip, hold the Grip by the tabs

making them face outward, align the Grip and slide it under

the Throttle Lever then press the Grip down until it seats onto

the top of the sander. Make sure the two “tabs” seat under the

inlet and exhaust.

10

Copyright © 1984-2016 CLAYTON Associates, Inc.

(732) 363-2100 • www.VacuumSanding.com

B-X3CT30-8

Revision 2019-05