3

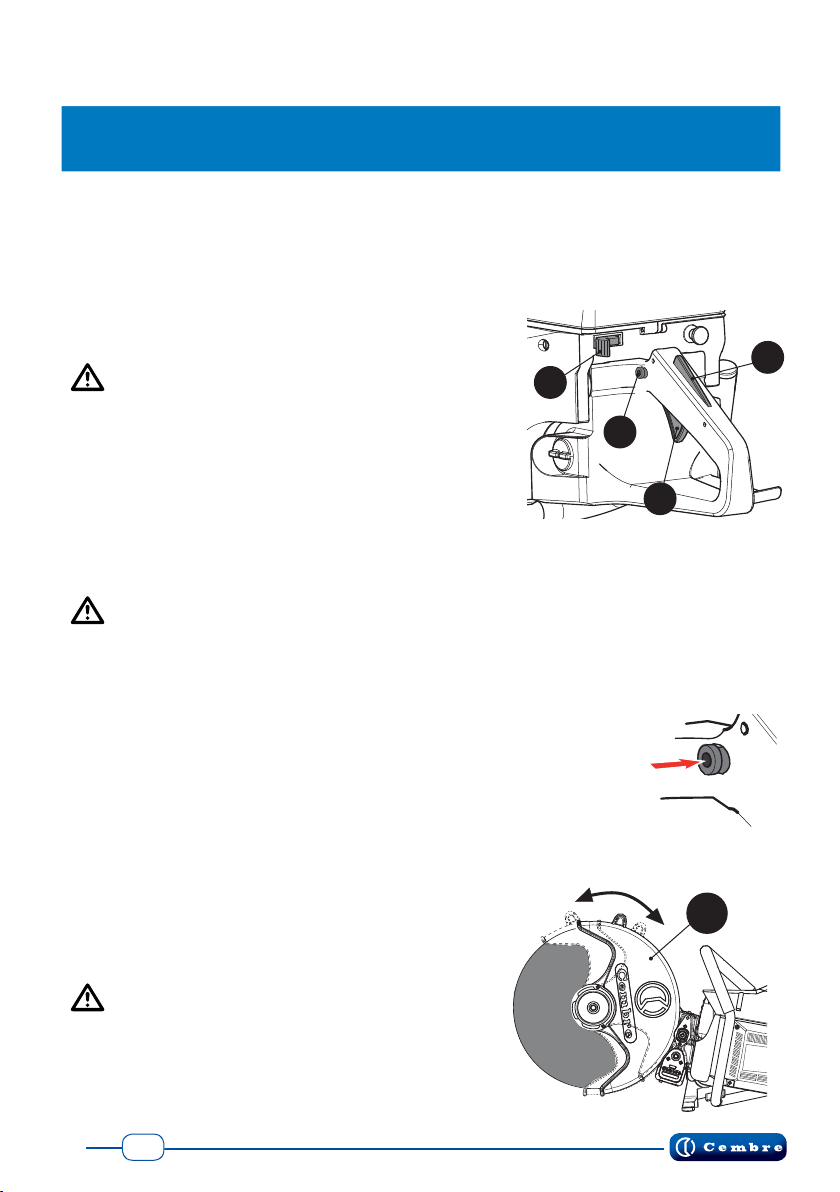

• Carefully follow the safety instructions set out by Cembre. Failure to observe these warnings

and the incorrect or improper use of the RAIL SAW may cause serious injury to the operator

and others close by.

• Always use personal protective equipment provided by your employer as result of a risk

evaluation prescribed by current national safety legislation, including: flame retardant

clothing, goggles or face shield, ear protectors, helmet, gloves, boots with anti slip soles

and steel toe-caps, airway protective mask.

• Anyone who uses or operates the RAIL SAW must first read this user manual carefully and be

familiar with the controls. The machine should only be used by trained, competent

personnel.

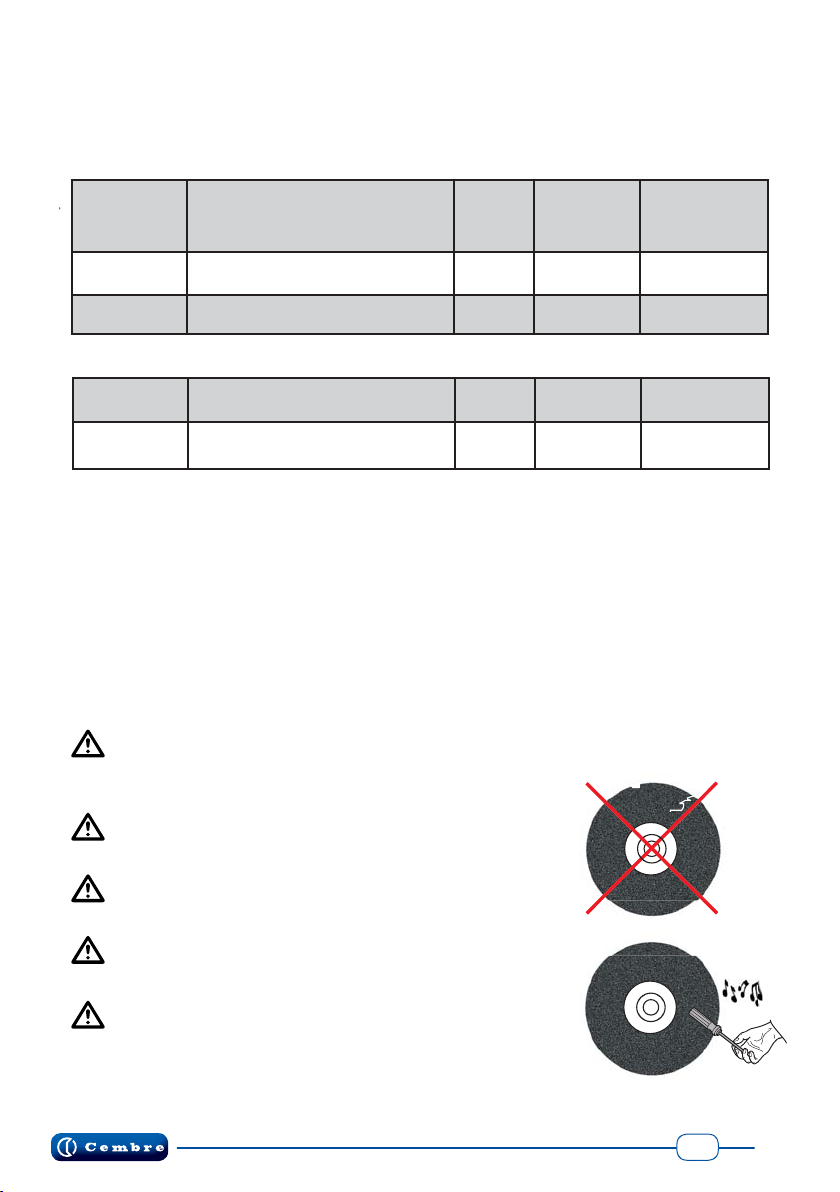

• Do not use the RAIL SAW for purposes other than those intended by Cembre or for

grinding operations using the side surface of the cutting disc as this may break and

cause serious injury. Never use a machine that is faulty, has been tampered with or

which has been modified from its original form.

• Control the surrounding area before operation; the safety distance around the RAIL

SAW for personnel not operating the machine should be at least 15 metres. Hot

sparks which fly off during cutting can cause fire if in the presence of flammable

materials such as dry grass, petrol, wood, etc.

• The RAIL SAW must only be used in conjunction with support arms supplied by Cembre.

• Never operate the RAIL SAW during personal ill health, when tired or under

the effects of alcohol, drugs or medicines which can alter the state of mind

and reduce reaction times; use good judgement in all situations.

• When operating, stand in a stable, secure position and grip the RAIL SAW tightly.

Be sure to work in good lighting conditions or with sufficient artificial lighting.

• Always keep a first aid kit and fire extinguisher on hand in order to intervene promptly

should remove the need arise.

• Avoid inhalation of Petrol fumes and exhaust emissions which contain Carbon Monoxide,

an odourless lethal gas. Ensure good ventilation.

• The fuel and its vapours are extremely flammable.

FIRE AND BURN HAZARD.

• Turn off the engine before refuelling. Dry any spilt fuel.

If the fuel comes into contact with clothing, change the clothing immediately.

Do not start the engine within 3 metres of the refuelling area.

• During transportation, always remove the cutting disc from the RAIL SAW.

Cfllfll h f i i bCbFil b h i