IF THE SAW DOES NOT OPERATE

1 Check that the isolator is switched on.

2 Check air supply is correct.

3 Valve in handle (part no. 50034) could be worn and/or the seal is

broken, blocking an air passage. Check and replace if necessary.

4 Valve unit (Part No. 1139) may be stuck. IT IS IMPERATIVE TO REMOVE

THE SAW FROM THE AIRLINE BEFORE COMMENCING THIS CHECK.

Remove the two hexagonal nuts, push out valve piston with a pencil,

keeping note which end is top. Clean with oil only, NEVER USE

ABRASIVE. Clean valve bore with oil, re‐fit piston from top, keeping the

seal at the top end. Tighten nuts and reconnect saw to air supply.

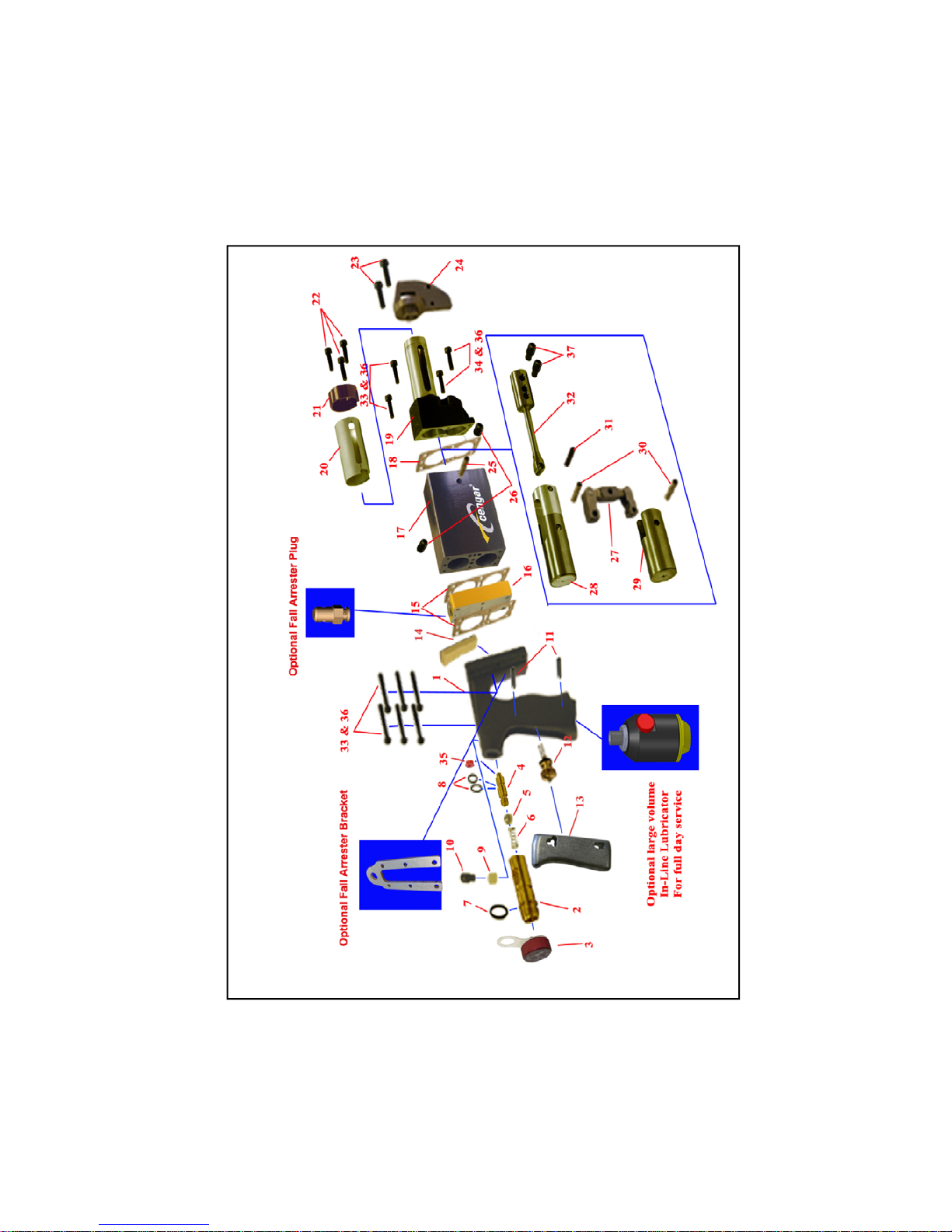

REPLACEMENTOFPISTONSON

1 The old pistons must be removed through the front of the body (blade

end) aer removing handle and front, push the top piston forward

(boom piston rearward) this will bring the link shoulders clear of the

cylinder walls.

2 Remove the centre sha, by firstly removing the two retaining screws

(Part No. 55516) and pushing the shaout carefully.

3 Push the top piston forward, (the boom piston will follow) unl

everything comes out.

4 Before refing, ensure that each piston is a smooth sliding fit in it’s

own bore, without being able to feel slackness.

5 Insert the pistons in to the bores from the front, in the same staggered

relaonship as during removal, to ensure that the link does not

damage the cylinder bores.

6 Refit the centre shaand securing screws, using a thread lock

adhesive on the screws.

7 Check that the pistons slide smoothly over the full travel, without

scking.

8

REPLACEMENTOFISOLATORASSEMBLY

1 All the parts of the isolator are available separately, however

for ease of service, we offer an isolator assembly (Part No 9552)

complete with retaining screw and détente spring, this has the

seat bonded in place already, and can be fied in seconds.