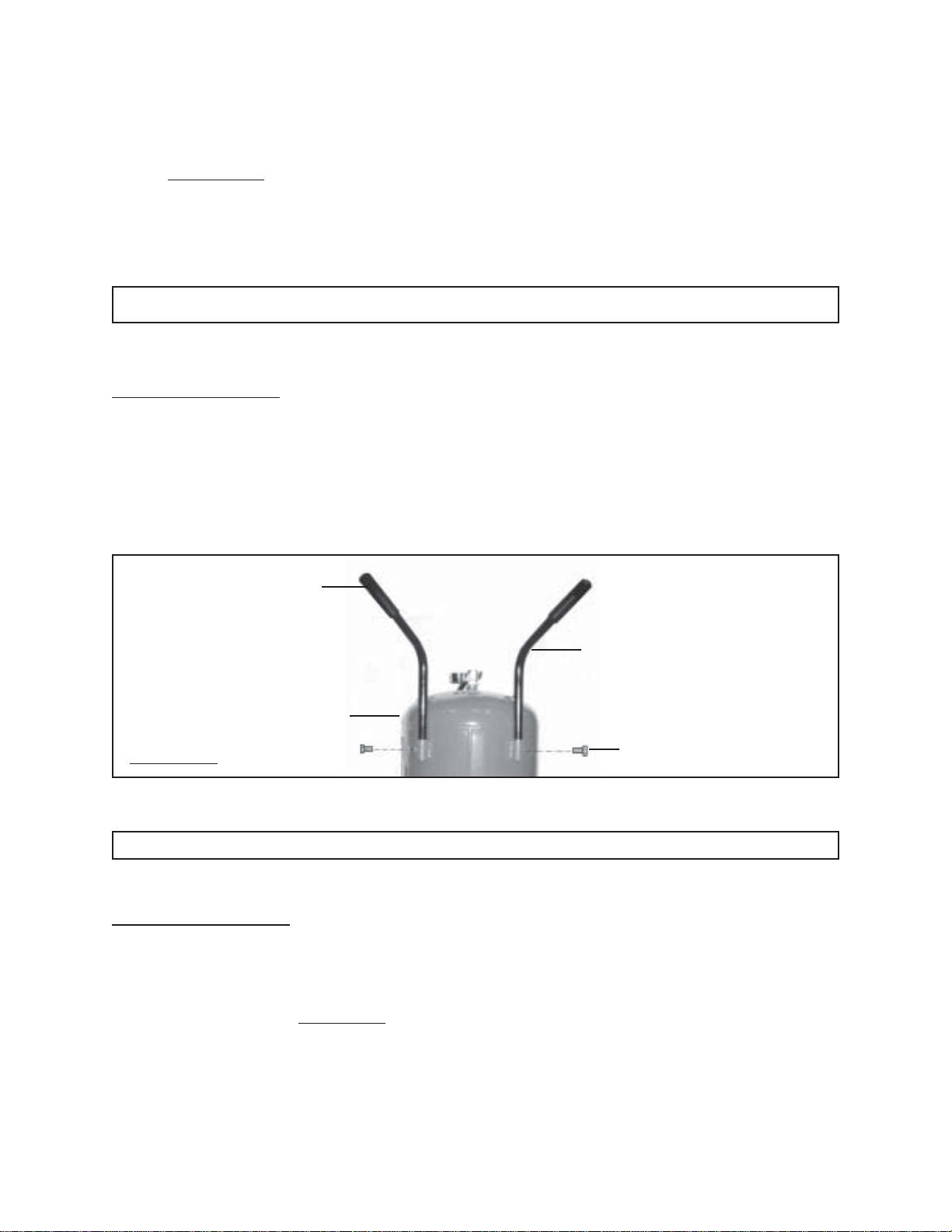

INSPECTION, MAINTENANCE, AND CLEANING

1. Before each use, inspect the general condition of the Air Tank. Check the Air

Tank for loose connections and joints, cracked, bent, or broken parts, damaged

Air Hose, damaged Tank, and any other condition that may affect the safe opera-

tion of the Air Tank. If a problem occurs, have the problem corrected before

further use. Do not use damaged equipment.

2. Daily: Slowly open the Drain Valve Assembly (1) by turning its Knob

counter-

clockwise

, and allow all moisture to drain from the Tank (15). Next, close the

Drain Valve Assembly by turning its Knob

clockwise

. Then, refill the Air Tank to

its maximum 125 PSI operating pressure rating.

3. When cleaning, use only water and a mild detergent. Then dry. Do not use

cleaners that are combustible or corrosive.

SKU 91064 PAGE 7

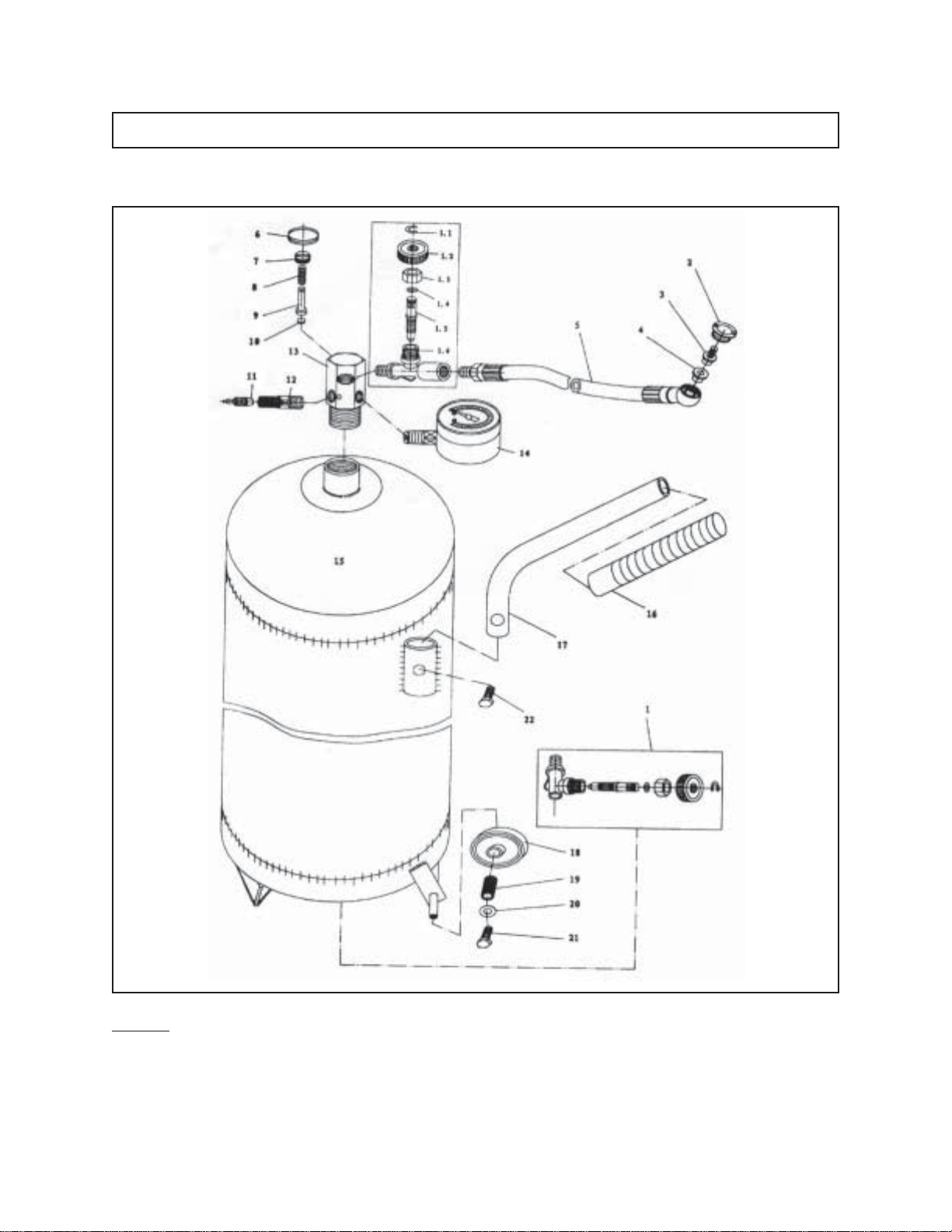

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN

THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES

ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF

THE PRODUCT. IN FACT, THE MANUFACTUER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL

REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNI-

CIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR

HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS

OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

PARTS LIST

Part

#Description Qt

. Part

#Description Qt

.

1 Drain Valve Assembly 2 9 Rod 1

1.1 Retaining Ring 2 10 Seal Washer 1

1.2 Air Outlet Knob 2 11 Core 1

1.3 Nut 2 12 Air Inlet Connecto

1

1.4 O-Ring 2 13 Valve Body 1

1.5 Rod 2 14 Pressure Gauge 1

1.6 Base 2 15 Tank 1

2 Cover 1 16 Handle Grip 2

3 Core 1 17 Handle 2

4 Seal Washer 1 18 Wheel 2

5 Air Hose 1 19 Bearing 2

6 Safety Release Valve 1 20 Washer 4

7 Nut 1 21 Retaining Ring 2

8 Spring 1 22 Bolt 2