Stagnoli DAPHNE 6 User manual

Istruzioni Instructions

1

GB – Barrier

DAPHNE 6

Istruzioni Instructions

2

Attention!

• This manual is for qualified installers only and not for the end user. It is the installer’s job to

explain to the user how the automatism works, about possible ha ards related to it and the

need for periodical maintenance.

• Installation must be carried out by qualified personnel only, in compliance with current

standards concerning automatic closing mechanisms.

• Daphne has been designed and made specifically to manage the access control of

vehicles. It is therefore forbidden to use the product for different reasons other than those

foreseen in this manual.

• It is forbidden to use it for any other purposes or improperly.

• Use original components only. Stagnoli is not liable for damages if any other components

are used.

• Make absolutely certain the power is disconnected before carrying out any work on the

device.

• Connect the power lead only to supply lines with adequate electrical protection.

•

Be particularly careful when evaluating the safety devices to install and their location.

Always install an emergency stop device that will cut power off in the case of necessity

Istruzioni Instructions

3

Blinker

DAPHNE

230V - 50Hz

3x1,5

Digital or key selector

Barrier

Poli emo clolumn-type photocell

Magnetic loop

Omnipolar switch

Istruzioni Instructions

4

DAPHNE’S Technical Details

Tecnical Details DAPHNE 6

Power Supply 230V~ (50Hz)

Current absorbed otor (A) 5

otor Power Supply 24V –––––

aximum Power ax 120W

Opening Time (sec) 10

Operating Temperature (°C) -20 ↔ +60

Duty Cycle (%) 70

IP Protection 44

Weight* (Kg) 40

ax. Length of arm (mt) 6

Dimensions

Max. 6000 mm

218

1100

380

Istruzioni Instructions

5

Manual Manoeuvre

• The manual manoeuvring of the arm should

only be carried out when the motor has

stopped due to a cut in the power supply

• Pull off the self releasing cylinder (1) and with

the Alan key (2) unblock the motor turning the

key in an anticlockwise direction.

• To re start the transmission, insert the cylinder

with the red key inside it. Once it has reached

the mechanical stop keep the cylinder still and

pull the red key out.

• Warning! Do not carry out the manual

manoeuvring if the arm is not fixed to the

motor.

Preliminary Checks

• ake sure that the ground is ideal for holding the cement base, in which the foundation

plate will be mounted.

• ake sure to foresee the passage of the cables as in the ideal set-up. The cable passage

is situated in a central position on the back of the barrier.

• ake sure that there are no obstacles in the way of the arm’s radius that could stop it’s

movement.

Fixing of the foundation plate (Fig. 2)

The barrier can be positioned either to the right or to the left of the passage. Therefore, once

decided the correct position proceed to the following steps:

• Prepare a cement base where you can insert the foundation plate with the relative rods.

• ake sure that the plate is perfectly flat, that it’s surface is perfectly clean and that the

rods are precisely perpendicular to the ground.

Fig. 2

2

1

Istruzioni Instructions

6

Fixing the barrier

• Take the top cover off by unscrewing the screws (Fig. 3).

• Open the barrier wings, position the barrier on the foundation plate making sure that the

lower holes correspond to the screwable rods and screw everything in place with the 10

nuts. (Fig.4).

Fig. 3 Fig. 4

Fixing in the aluminium bar

• Fix down the bar holder bracket without wholly tightening down the screws (Fig. 5).

• Insert the 80mm diameter bar, resting still on the back support, and screw down

definitively the 8 screws (Fig.6).

• Assemble the fixing joint on the 80mm bar and insert the 60 mm bar into it.

• Fix down everything with the provided screws.

Fig. 5 Fig. 6

Istruzioni Instructions

7

Adjusting the arm:

the standard opening of the barrier is in an anticlockwise direction as in

(Fig. 7).

Fig. 7

• To invert the opening direction of the arm, move the spring to the opposite position (Fig.8)

and invert the connection of the electric motor to the control panel (Fig.9).

1

8

APM1

9

CHM1

10

LAMP

11

M1

LAMP

12

13

LC

LC

24V 120W

Fig.8 Fig. 9

Istruzioni Instructions

8

• Balance the barrier’s arm adjusting the screwable rods. The arm must be in equilibrium in

the half way position (45°) (Fig. 10).

45°

Fig. 10

• Proceed with the programming of the control panel following the specific electrical

instructions and after having carried out the complete programming regulate the position

of the arm’s limit switches, lowering or raising the relative rubber antivibration drums (1)

(Fig. 11).

N.B Warning it is compulsory to use the fixed support for the bar.

1

Fig. 11

Istruzioni Instructions

9

Adjusting the chain’s tension

The chain’s tension is adjusted directly in the warehouse, however, if you notice that the chain is

slightly slack, adjust, using screws (1) as in example (Fig. 12).

1

Slackening

Tightening

Fig. 12

Ordinary Maintenance

It is advisable, after installation, to carry out checks on the moving parts, at least every 6 months:

• Check the balance of the arm ( if necessary rebalance the arm adjusting the screwable

rods) (see Fig. 10).

• Check the correct alignment of the arm.

• Verifying the tension on the transmission chain.

Every 500,000 manoeuvres carry out a revision of the following parts.

• Replace the rubber antivibration drums

• Check that the spring is balanced

• Check that the body of the barrier is securely grounded, check that the arm is still

tightly attached and check that the motor is still securely fixed.

• Check the relative functionality and efficiency of the control panel and the safety

accessories.

Fixing the photocell (optional):

Open the barrier door and fix the photocell as indicated in

figure.

Istruzioni Instructions

10

Connecting integrated lamps :

Open the top cover, unscrew the two lampholders and connect them as per the following

diagram:

2

-24

3

+24

4

-BAT

5

+BAT

6

VAC

7

VAC

F3 (T3.15A, 250V)

STOP

F.CL.

F.OP.

F1 (T10A, 250V)

A

B

C

D

E

F

G

H

I

J

RST

8

APM1

9

CHM1

10

LAMP

11

M1

LAMP

12

13

LC

LC

SIG.

- ENC

+ ENC

14

15

16

17

18

19

20

21

22

COM

F.OP

F.CL

STOP

PARZ

AP/CH

24

23 25 26

CH2 GND SIGCH2

DISPLAY

P1

P2

24V 120W

CONNETTORE MOLEX

F2 (T0.63A, 250V)

POWER

1

N.B Warning the integrated lamp’s bulbs must not have a total power greater than 20W. The bulbs

must always be connected in parallel.

Fixing the digital or key pad (optional):

open the barrier door, take off the cover (1) and fix

the pad as indicated in figure.

1

2

Istruzioni Instructions

11

Other manuals for DAPHNE 6

1

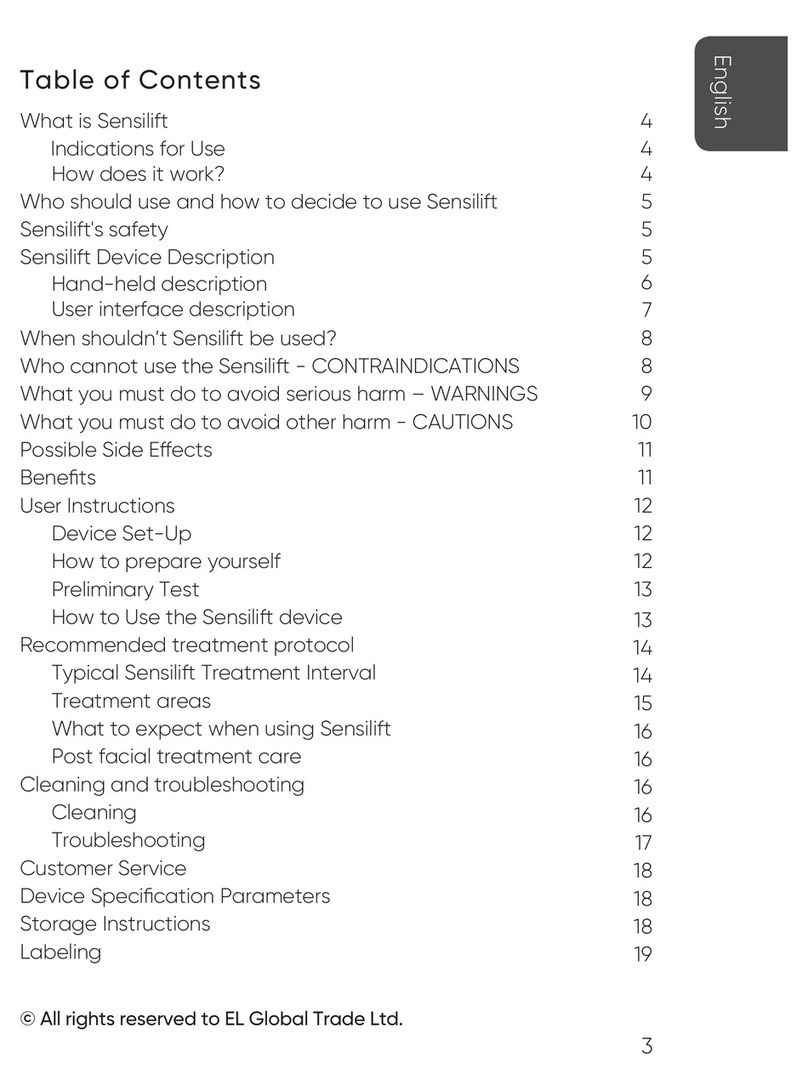

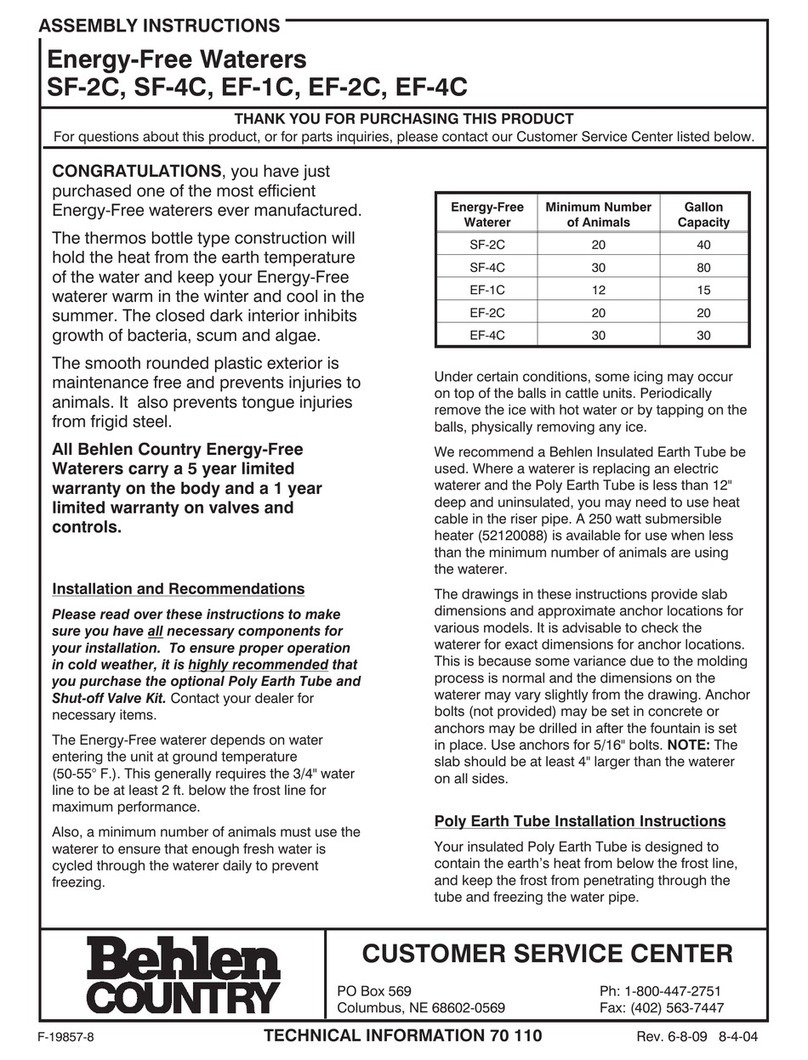

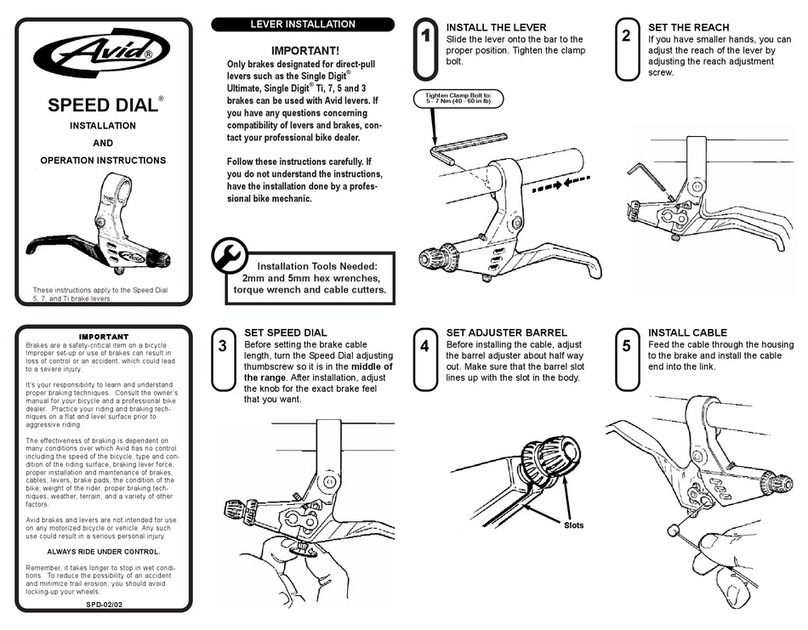

Table of contents

Popular Other manuals by other brands

Rothenberger

Rothenberger Roklima Plus 4F Instructions for use

Digital Watchdog

Digital Watchdog CP-01 instruction manual

Abicor Binzel

Abicor Binzel TCS-FP operating instructions

eSSL

eSSL TS1000 series user manual

Oase

Oase Biorb 46000 operating instructions

Rheem

Rheem RRNA-B SERIES installation instructions

Balluff

Balluff BIS V-6108-048-C002 Technical Reference, Operating Manual

NEC

NEC DSX PROGRAMMERS - Reference

Elitech

Elitech RC-5 operation instruction

Tetra

Tetra LightWave Timer instruction manual

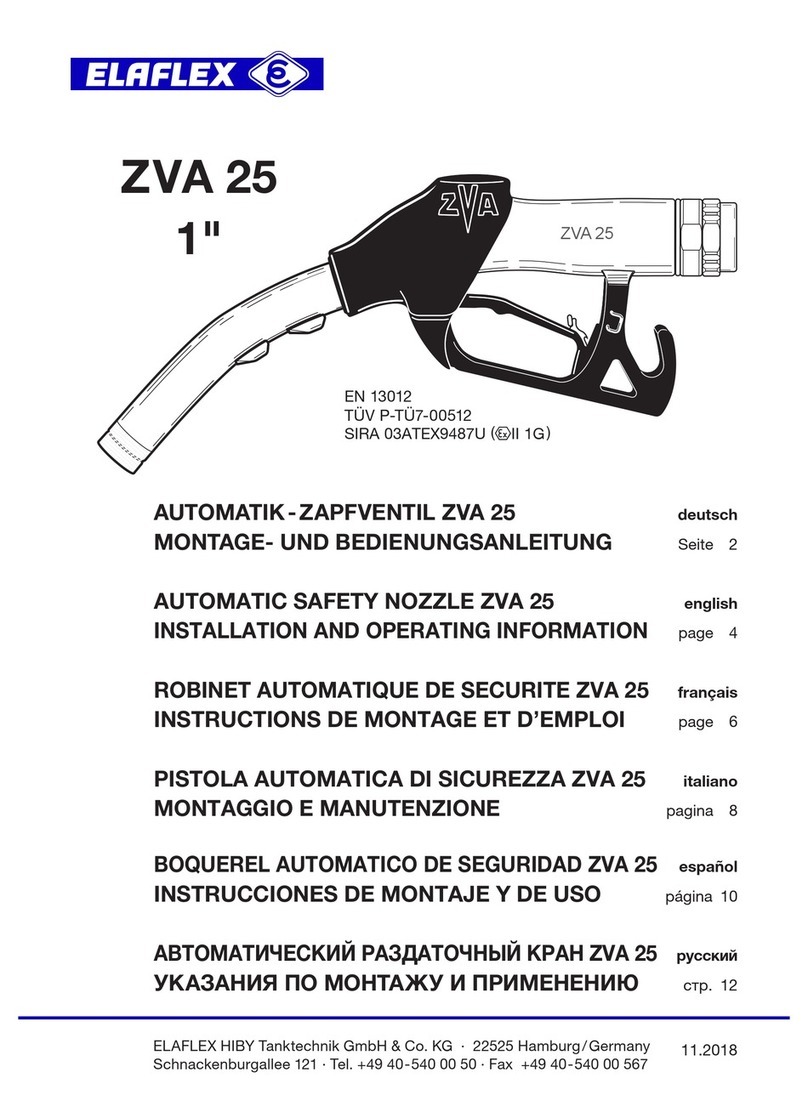

Elaflex

Elaflex ZVA 25 Installation and operating information

Torklift

Torklift A7200 Important owner-operator installation instructions